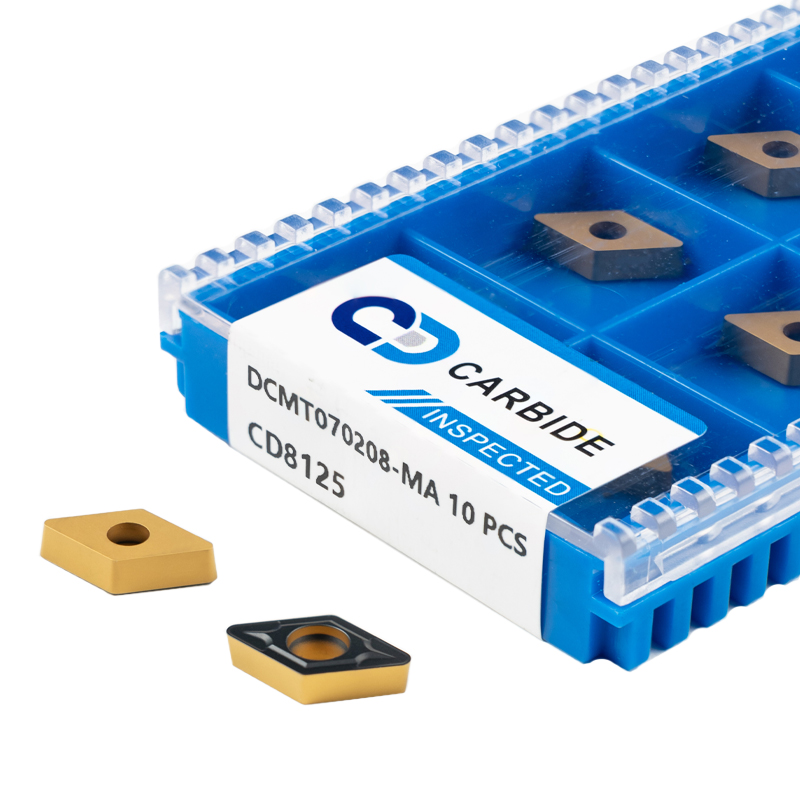

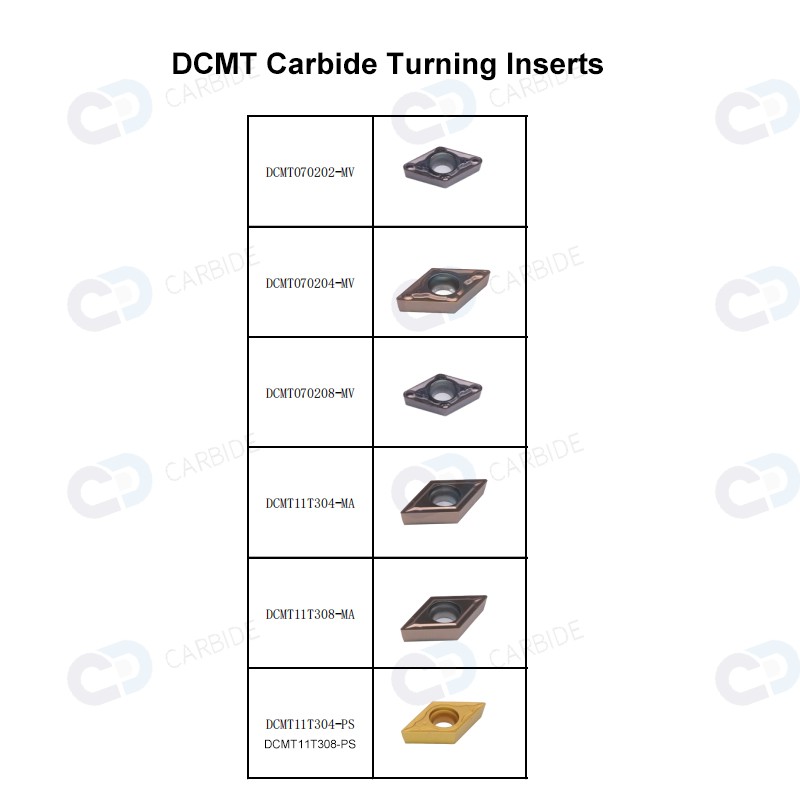

- Grade: CD8125

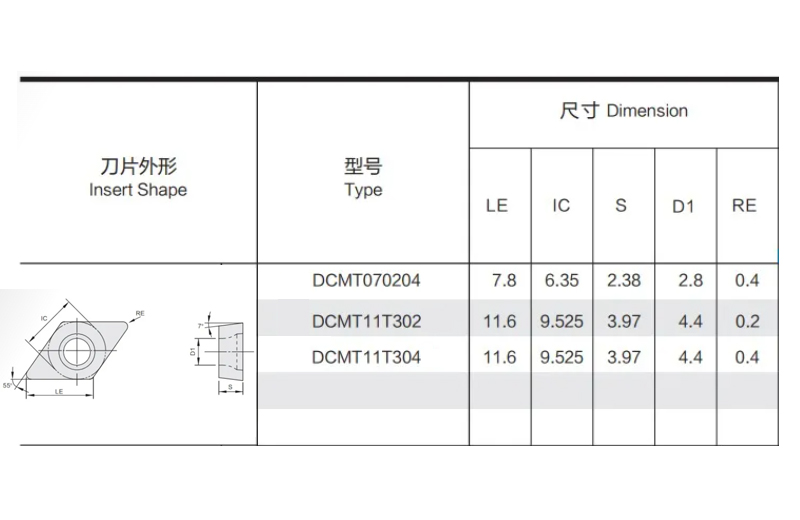

- Model: DCMT070204-MA DCMT070208-MA

- Application: CNC Lathe Machine

- Cutting Condition: High Precision Finishing Cutting

DISGRIFIAD

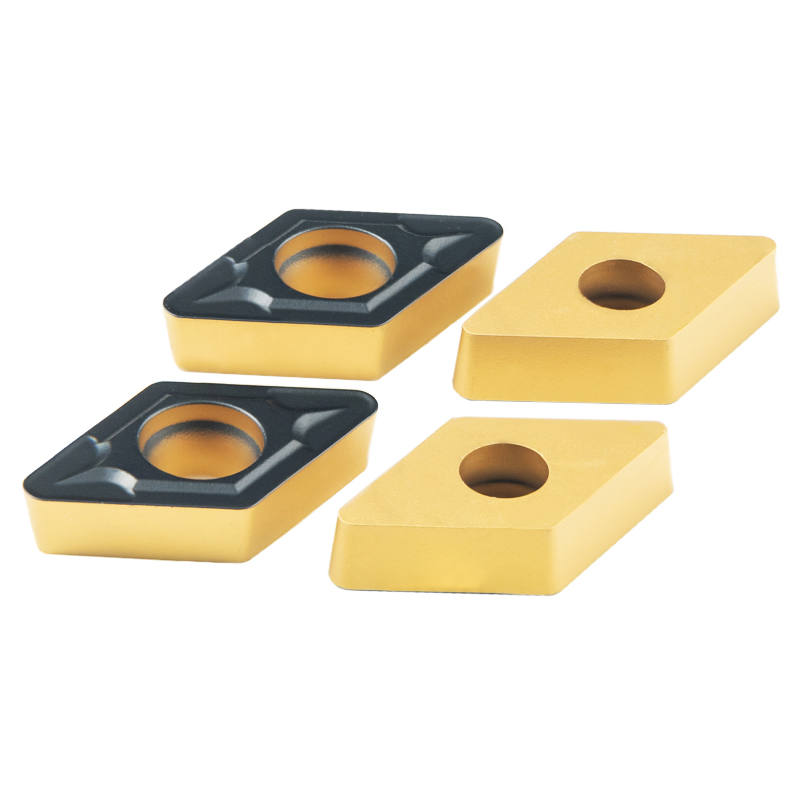

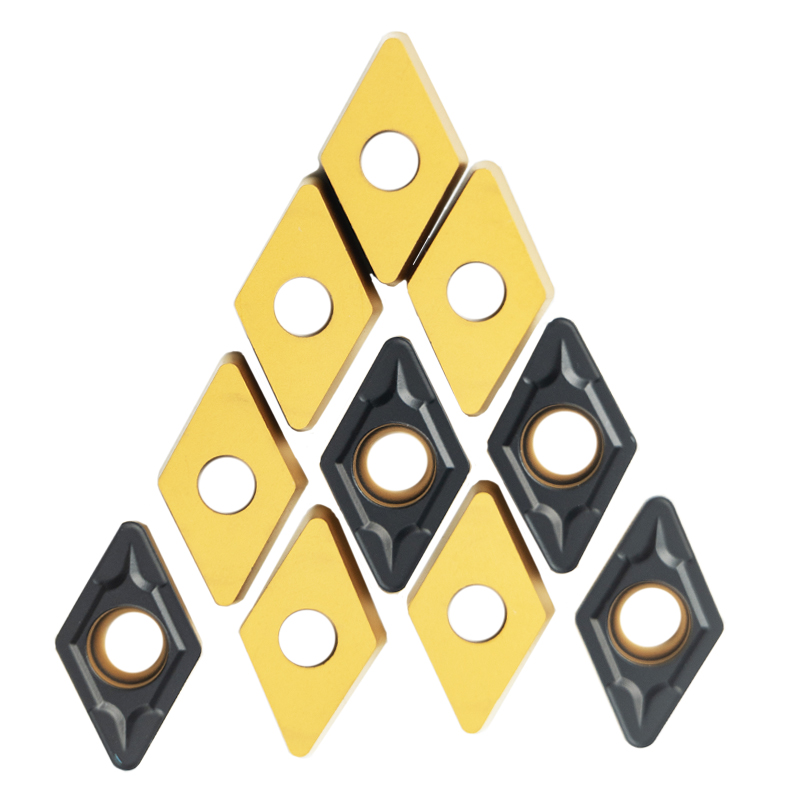

DCMT Carbide Cutting Inserts DCMT070204-MA DCMT070208-MA CNC Lathe Turning Inserts for Steel General machining

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

FAQ

1) Pryd alla i gael y pris?

Rydym fel arfer yn dyfynnu o fewn 24 awr ar ôl i ni gael eich ymholiad. Os ydych yn frys iawn i gael y pris, ffoniwch ni neu dywedwch wrthym yn eich e-bost fel y byddwn yn ystyried eich blaenoriaeth ymholiad.

2) Sut alla i gael sampl i wirio'ch ansawdd?

Ar ôl cadarnhad pris, gallwch ofyn am samplau i wirio ein hansawdd. Os mai dim ond sampl wag sydd ei angen arnoch i wirio ansawdd y dyluniad a'r papur, byddwn yn darparu sampl i chi am ddim, cyn belled â'ch bod yn fforddio'r cludo nwyddau cyflym.

3) Pa mor hir y gallaf ddisgwyl cael y sampl?

Ar ôl i chi dalu'r tâl sampl ac anfon ffeiliau wedi'u cadarnhau atom, bydd y samplau'n barod i'w danfon mewn 3-7 diwrnod. Bydd y samplau'n cael eu hanfon atoch trwy express ac yn cyrraedd mewn 3-7 diwrnod gwaith. Gallwch ddefnyddio eich cyfrif cyflym eich hun neu ein rhagdalu os nad oes gennych gyfrif.

4) Am ba mor hir mae'r weithdrefn gyfan yn cael ei gweithio allan?

Ar ôl i chi osod archeb, mae'r amser trin cynhyrchu tua 20-25 diwrnod. Mae angen 7 diwrnod i baratoi'r holl bethau yna 15 diwrnod ar gyfer gweithgynhyrchu.

5) Beth am y dyddiad cludo a dosbarthu?

Fel arfer rydym yn defnyddio llwyth i transprot y goods.It yw tua 7-25 days.It hefyd denpends ar ba coutry a phorthladd ydych yn. Gallai fod yn fyrrach os oes angen i anfon y nwyddau fel Asiaidd. Os bydd rhai argyfyngau gallwn anfon y nwyddau trwy air express, cyn belled â'ch bod yn fforddio'r gost traffig.

6) Ydych chi'n gwmni masnachu neu'n wneuthurwr?

Rydym yn wneuthurwr proffesiynol. Rydym nid yn unig yn berchen ar ein ffatri offer, ond mae gennym hefyd ffatri carbid smentio.

7) Ble mae eich ffatri wedi'i lleoli?

Rydym wedi ein lleoli yn ninas Zhuzhou, Talaith Hunan ., Tref sylfaen carbid twngsten Tsieina

8) Pa mor hir y gallaf ddisgwyl cael y sampl?

Ar ôl i chi dalu'r tâl sampl ac anfon ffeiliau wedi'u cadarnhau atom, bydd y samplau'n barod i'w danfon mewn 3-7 diwrnod. Bydd y samplau'n cael eu hanfon atoch trwy express ac yn cyrraedd mewn 3-5 diwrnod gwaith. Gallwch ddefnyddio eich cyfrif cyflym eich hun neu ein rhagdalu os nad oes gennych gyfrif.

9) Beth am eich stoc?

Mae gennym nifer fawr o gynhyrchion mewn stoc, mae mathau a meintiau rheolaidd i gyd mewn stoc.

10) A yw cludo am ddim yn bosibl?

Nid ydym yn cynnig gwasanaeth cludo am ddim. Gallwn gael gostyngiad os ydych chi'n prynu nifer fawr o gynhyrchion

Mae croeso i chi gysylltu â mi:

Aimee

Rheolwr Gwerthiant

Zhuzhou Chuangde smentio carbid Co Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Dinas Zhuzhou.

E-bost: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688