- Tungsten carbide

- Coating: PVD

- Hardness: 92HRA

Disgrifiadau

CCMT09T302-FM4 Turning Carbide Inserts in China

1.Product description:

The advantages:

1. Good chip control for steel machining . Provides perfect turning surface of the workpiece .

2. CVD coating ensures the high wear resistance.

3. Less tool breakage, saving costs and reduce the cost of each component to increase the profits .

4. Long tool life, get higher machine utilization and higher production.

5. A reliable and secure performance every time.

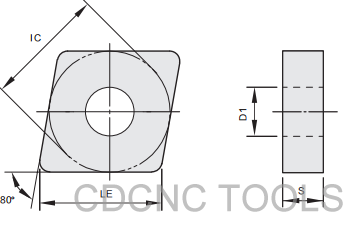

2.design drawings:

Insert Shape |

Type | Dimension | |||||

LE |

IC |

S |

D1 |

RE | |||

| Semi Finishing | CNMG120404-OMM | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

CNMG120408-OMM | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG160608-OMM | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 | ||

| CNMG090308-MF | 9.7 | 9.525 | 3.18 | 3.81 | 0.8 | |

CNMG120408-MF | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG120412-MF | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

CNMG160612-MF | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 | ||

| CNMG120404-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 | |

CNMG120408-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG120412-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

| Roughing | CNMG120408-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

CNMG120412-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

CNMG120416-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 1.6 | ||

CNMG160608-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 | ||

CNMG160612-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 1.2 | ||

CNMG160616-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 | ||

CNMG190608-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 0.8 | ||

CNMG190612-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 1.2 | ||

CNMG190616-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 1.6 | ||

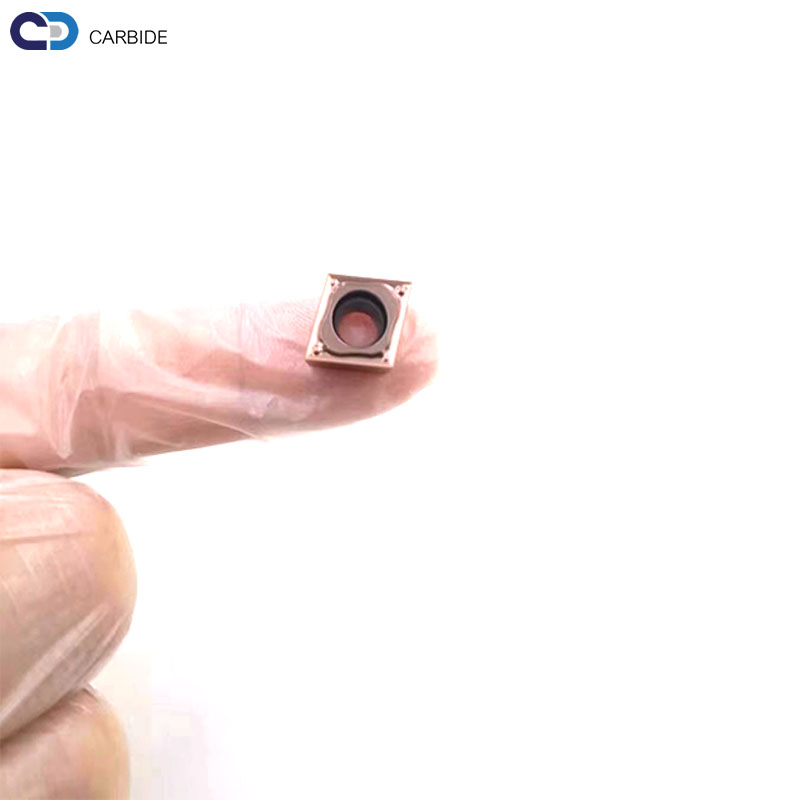

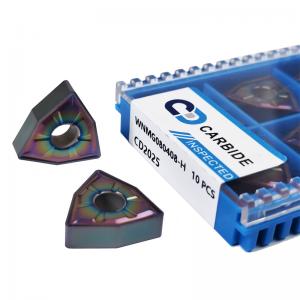

3. product show:

5.Grade:

| Grade for Turning Inserts | ||||

| GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

| CD8025 | CVD | golden yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. MT-TiCN+Al2O3+TiN coating has very good surface quality and help to recognize wear easily. It is suitable for semi-finishing and finishing steel machining. |

| (MT-TiCN+Al2O3+TiN) | ||||

| CD8125 | CVD | black | P10-P40 | The carbide substrate have mild cobalt content and high cubic content, combining with thick TiCN and Al2O3, treated by sepcial technology after coating treatment, which gives inserts strong wearing resistance. It is prority for semi-finishing to finishing steel machining. |

| (Multi-TiCN+Al2O3) | ||||

| CD8020 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel. |

| CD8010 | CVD | black | K10-K30 | The medium-coarse substrate combine with thick TiCN and textured Al2O3, after special coating treatment, it has strong |

| (thick TiCN+ textured Al2O3) | wear-resistance. The grade is suitable for high-speed semi-finishing cast iron turning under stable working condition. | |||

FAQ

1) Pryd alla i gael y pris?

Rydym fel arfer yn dyfynnu o fewn 24 awr ar ôl i ni gael eich ymholiad. Os ydych yn frys iawn i gael y pris, ffoniwch ni neu dywedwch wrthym yn eich e-bost fel y byddwn yn ystyried eich blaenoriaeth ymholiad.

2) Sut alla i gael sampl i wirio'ch ansawdd?

Ar ôl cadarnhad pris, gallwch ofyn am samplau i wirio ein hansawdd. Os mai dim ond sampl wag sydd ei angen arnoch i wirio ansawdd y dyluniad a'r papur, byddwn yn darparu sampl i chi am ddim, cyn belled â'ch bod yn fforddio'r cludo nwyddau cyflym.

3) Pa mor hir y gallaf ddisgwyl cael y sampl?

Ar ôl i chi dalu'r tâl sampl ac anfon ffeiliau wedi'u cadarnhau atom, bydd y samplau'n barod i'w danfon mewn 3-7 diwrnod. Bydd y samplau'n cael eu hanfon atoch trwy express ac yn cyrraedd mewn 3-7 diwrnod gwaith. Gallwch ddefnyddio eich cyfrif cyflym eich hun neu ein rhagdalu os nad oes gennych gyfrif.

4) Am ba mor hir mae'r weithdrefn gyfan yn cael ei gweithio allan?

Ar ôl i chi osod archeb, mae'r amser trin cynhyrchu tua 20-25 diwrnod. Mae angen 7 diwrnod i baratoi'r holl bethau yna 15 diwrnod ar gyfer gweithgynhyrchu.

5) Beth am y dyddiad cludo a dosbarthu?

Fel arfer rydym yn defnyddio llwyth i transprot y goods.It yw tua 7-25 days.It hefyd denpends ar ba coutry a phorthladd ydych yn. Gallai fod yn fyrrach os oes angen i anfon y nwyddau fel Asiaidd. Os bydd rhai argyfyngau gallwn anfon y nwyddau trwy air express, cyn belled â'ch bod yn fforddio'r gost traffig.

6) Ydych chi'n gwmni masnachu neu'n wneuthurwr?

Rydym yn wneuthurwr proffesiynol. Rydym nid yn unig yn berchen ar ein ffatri offer, ond mae gennym hefyd ffatri carbid smentio.

7) Ble mae eich ffatri wedi'i lleoli?

Rydym wedi ein lleoli yn ninas Zhuzhou, Talaith Hunan ., Tref sylfaen carbid twngsten Tsieina

8) Pa mor hir y gallaf ddisgwyl cael y sampl?

Ar ôl i chi dalu'r tâl sampl ac anfon ffeiliau wedi'u cadarnhau atom, bydd y samplau'n barod i'w danfon mewn 3-7 diwrnod. Bydd y samplau'n cael eu hanfon atoch trwy express ac yn cyrraedd mewn 3-5 diwrnod gwaith. Gallwch ddefnyddio eich cyfrif cyflym eich hun neu ein rhagdalu os nad oes gennych gyfrif.

9) Beth am eich stoc?

Mae gennym nifer fawr o gynhyrchion mewn stoc, mae mathau a meintiau rheolaidd i gyd mewn stoc.

10) A yw cludo am ddim yn bosibl?

Nid ydym yn cynnig gwasanaeth cludo am ddim. Gallwn gael gostyngiad os ydych chi'n prynu nifer fawr o gynhyrchion

Mae croeso i chi gysylltu â mi:

Aimee

Rheolwr Gwerthiant

Zhuzhou Chuangde smentio carbid Co Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Dinas Zhuzhou.

E-bost: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688