- Tungsten carbide

- Coating: PVD

- Hardness: 92HRA

BESKRIUWING

CCMT09T302-FM4 Turning Carbide Inserts in China

1.Product description:

The advantages:

1. Good chip control for steel machining . Provides perfect turning surface of the workpiece .

2. CVD coating ensures the high wear resistance.

3. Less tool breakage, saving costs and reduce the cost of each component to increase the profits .

4. Long tool life, get higher machine utilization and higher production.

5. A reliable and secure performance every time.

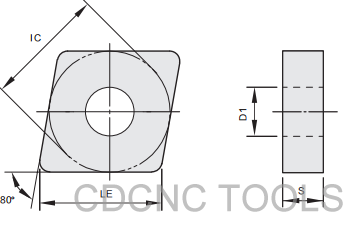

2.design drawings:

Insert Shape |

Type | Dimension | |||||

LE |

IC |

S |

D1 |

RE | |||

| Semi Finishing | CNMG120404-OMM | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

CNMG120408-OMM | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG160608-OMM | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 | ||

| CNMG090308-MF | 9.7 | 9.525 | 3.18 | 3.81 | 0.8 | |

CNMG120408-MF | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG120412-MF | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

CNMG160612-MF | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 | ||

| CNMG120404-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 | |

CNMG120408-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG120412-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

| Roughing | CNMG120408-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

CNMG120412-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

CNMG120416-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 1.6 | ||

CNMG160608-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 | ||

CNMG160612-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 1.2 | ||

CNMG160616-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 | ||

CNMG190608-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 0.8 | ||

CNMG190612-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 1.2 | ||

CNMG190616-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 1.6 | ||

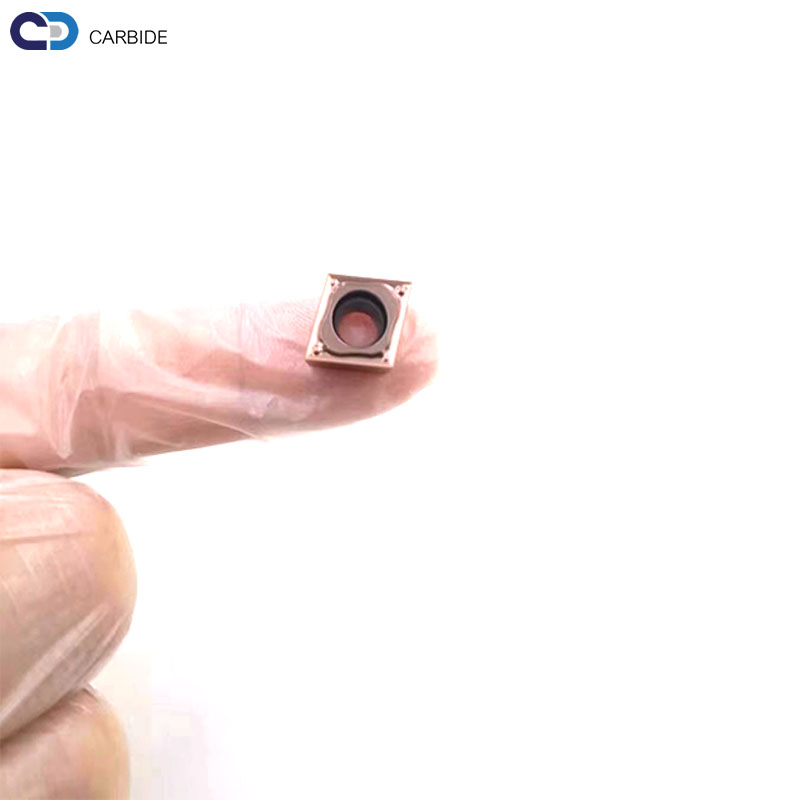

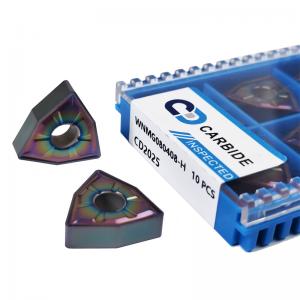

3. product show:

5.Grade:

| Grade for Turning Inserts | ||||

| GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

| CD8025 | CVD | golden yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. MT-TiCN+Al2O3+TiN coating has very good surface quality and help to recognize wear easily. It is suitable for semi-finishing and finishing steel machining. |

| (MT-TiCN+Al2O3+TiN) | ||||

| CD8125 | CVD | black | P10-P40 | The carbide substrate have mild cobalt content and high cubic content, combining with thick TiCN and Al2O3, treated by sepcial technology after coating treatment, which gives inserts strong wearing resistance. It is prority for semi-finishing to finishing steel machining. |

| (Multi-TiCN+Al2O3) | ||||

| CD8020 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel. |

| CD8010 | CVD | black | K10-K30 | The medium-coarse substrate combine with thick TiCN and textured Al2O3, after special coating treatment, it has strong |

| (thick TiCN+ textured Al2O3) | wear-resistance. The grade is suitable for high-speed semi-finishing cast iron turning under stable working condition. | |||

FAQ

1) Wannear kin ik de priis krije?

Wy sitearje normaal binnen 24 oeren nei't wy jo fraach krije. As jo heul driuwend binne om de priis te krijen, belje ús dan asjebleaft of fertel ús yn jo e-post, sadat wy jo ûndersyksprioriteit sille beskôgje.

2) Hoe kin ik in stekproef krije om jo kwaliteit te kontrolearjen?

Nei priisbefêstiging kinne jo samples fereaskje om ús kwaliteit te kontrolearjen. As jo gewoan in lege stekproef nedich binne om it ûntwerp en papierkwaliteit te kontrolearjen, sille wy jo fergees sample leverje, salang't jo de ekspresfracht betelje.

3) Hoe lang kin ik ferwachtsje om de stekproef te krijen?

Nei't jo de samplekosten betelje en ús befêstige bestannen stjoere, sille de samples yn 3-7 dagen klear wêze foar levering. De samples wurde fia ekspresje nei jo stjoerd en komme yn 3-7 wurkdagen. Jo kinne jo eigen express-akkount brûke of ús foarôf betelje as jo gjin akkount hawwe.

4) Hoe lang wurdt de hiele proseduere útwurke?

Nei't jo in bestelling pleatse, is de produksjetiid sawat 20-25 dagen. Wy hawwe 7 dagen nedich om al it spul te meitsjen, dan 15 dagen foar fabrikaazje.

5) Wat oer de transport- en leveringsdatum?

Normaal brûke wy ferstjoering om it guod te transprotearjen. It giet oer 7-25 dagen. It hinget ek ôf fan hokker lân en haven jo binne. It kin koarter wêze as jo it guod lykas Aziatyske stjoere moatte. As d'r wat needgefallen binne, kinne wy it guod fia air express stjoere, salang't jo de ferkearskosten betelje.

6) Binne jo hannelsbedriuw as fabrikant?

Wy binne profesjonele fabrikant. Wy hawwe net allinich ús arkfabryk, mar hawwe ek cemented carbide fabryk.

7) Wêr leit jo fabryk?

Wy binne fêstige yn Zhuzhou stêd, Hunan Provinsje., wolfraam carbid basis stêd fan Sina

8) Hoe lang kin ik ferwachtsje om de stekproef te krijen?

Nei't jo de samplekosten betelje en ús befêstige bestannen stjoere, sille de samples yn 3-7 dagen klear wêze foar levering. De samples wurde fia ekspresje nei jo stjoerd en komme yn 3-5 wurkdagen. Jo kinne jo eigen express-akkount brûke of ús foarôf betelje as jo gjin akkount hawwe.

9) Hoe sit it mei jo stock?

Wy hawwe produkten yn grutte kwantiteit op foarried, reguliere soarten en maten binne allegear op foarried.

10) Is fergees ferstjoeren mooglik?

Wy biede gjin fergese ferstjoertsjinst. Wy kinne hawwe in koarting as jo keapje in grutte kwantiteit produkten

Fiel dy frij Kontakt mei my op te nimmen :

Aimee

Sales manager

Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

E-post: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688