404 Flaterpagina

- Thús

- |- Oer ús

- |- Products

- |-- Turning Inserts ark

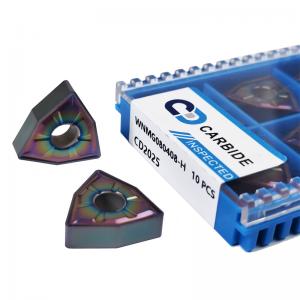

- |--- Turning ark foar Steel Processing

- |--- Turning ark foar Stainless Steel Processing

- |--- Turning ark foar Cast Iron Processing

- |--- Drilling Inserts

- |--- Turning ark foar Aluminium Processing

- |--- CBN & PCD Inserts

- |--- Cermet Inserts

- |--- CNC Tool Holder

- |--- Orizjinele Inserts

- |-- Solid Carbide End Mills

- |--- Houtwurkjende snijwurk

- |--- 2/4 Corner Radius End Mills

- |--- 2/4 Flutes Ball Nose End Mills

- |--- 2/4 Flutes Flat End Mills

- |--- HRC55 Square End molens foar Cutting

- |--- Roughing End Mills

- |--- Chamfer einmole

- |--- Solid Carbide Drills

- |--- Carbide Reamers

- |-- Cermet End Mill

- |- Download

- |-- Help dokumint

- |-- triem download

- |- Nijs

- |-- Bedriuw nij

- |--- Ofdieling nijs

- |-- Yndustry nijs

- |- Foto

- |-- Fotoalbum fan wurknimmers

- |-- Klant gefal

- |- Kontakt mei ús opnimme