404 Duilleag mearachd

- Dachaigh

- |- Mu ar deidhinn

- |- Bathar

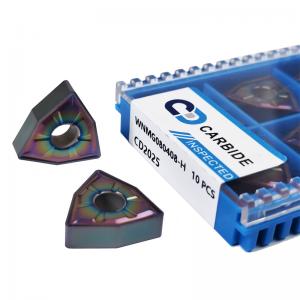

- |-- Tionndaidh innealan Inserts

- |--- Innealan tionndaidh airson Steel Processing

- |--- Innealan tionndaidh airson giullachd stàilinn gun staoin

- |--- Innealan tionndaidh airson Pròiseas Iarainn Cast

- |--- Drilling Inserts

- |--- Innealan tionndaidh airson Pròiseas Aluminium

- |--- Cuir a-steach CBN & PCD

- |--- Cermet a’ dol a-steach

- |--- Neach-gleidhidh inneal CNC

- |--- Cuir a-steach tùsail

- |-- Muilnean crìochnachaidh carbide soladach

- |--- Innealan gearradh fiodha

- |--- Muilnean crìochnachaidh 2/4 Corner Radius

- |--- 2/4 Muilnean Deireadh Sròn Ball Flutes

- |--- 2/4 Flutes Muilnean Flat End

- |--- Muilnean Ceàrnag HRC55 airson Gearradh

- |--- Muilnean Roughing End

- |--- Muileann crìochnachaidh chamfer

- |--- Drilean carbide cruaidh

- |--- Carbide Reamers

- |-- Muileann Ceann Cermet

- |- Luchdaich sìos

- |-- Sgrìobhainn cuideachaidh

- |-- luchdachadh sìos

- |- Naidheachdan

- |-- Companaidh ùr

- |--- Roinn naidheachdan

- |-- Naidheachdan gnìomhachas

- |- Dealbh

- |-- Leabhar dhealbhan de luchd-obrach a

- |-- Cùis teachdaiche

- |- Cuir fios thugainn