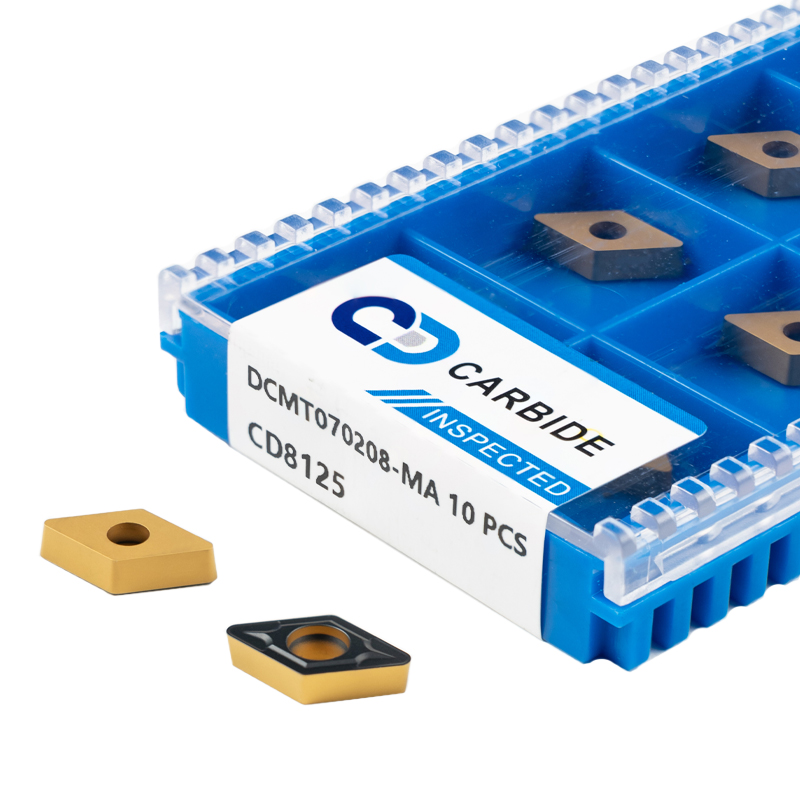

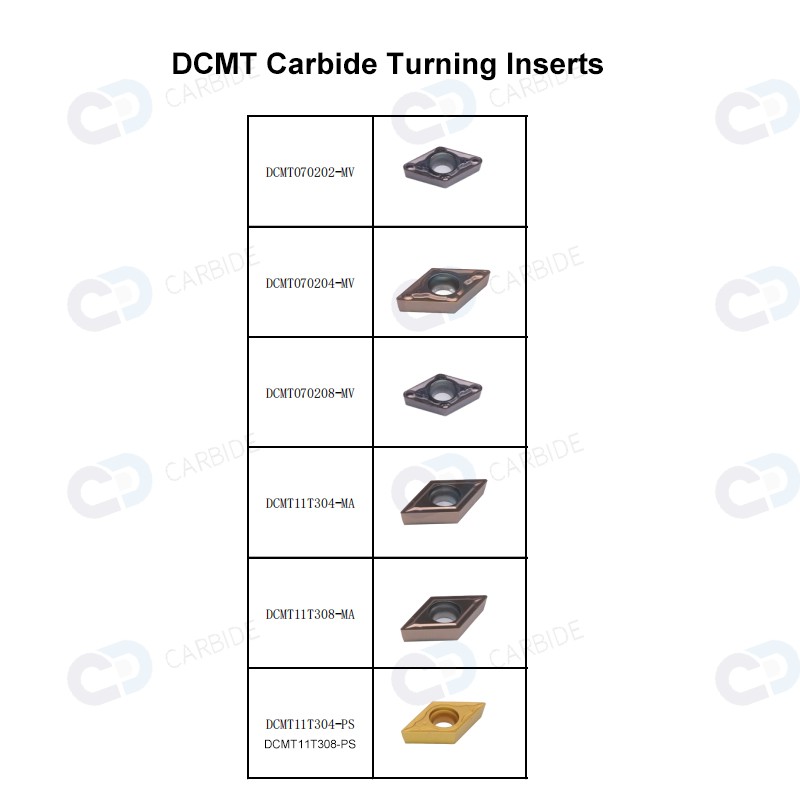

- Grade: CD8125

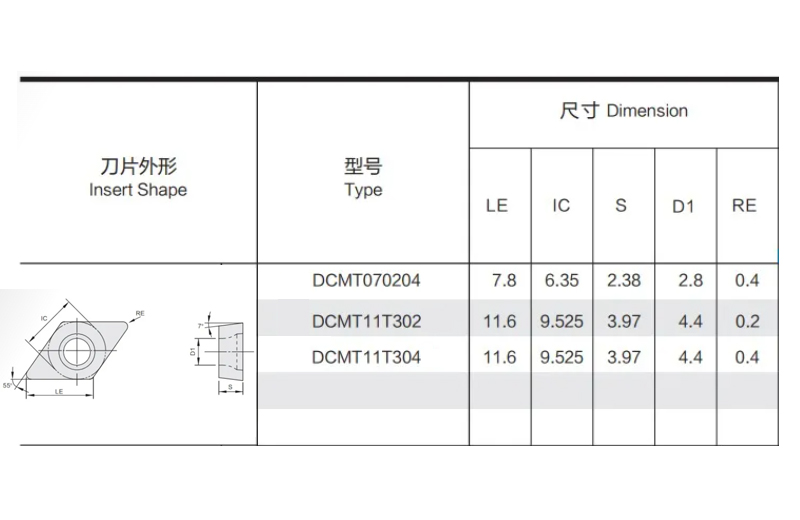

- Model: DCMT070204-MA DCMT070208-MA

- Application: CNC Lathe Machine

- Cutting Condition: High Precision Finishing Cutting

BAYANI

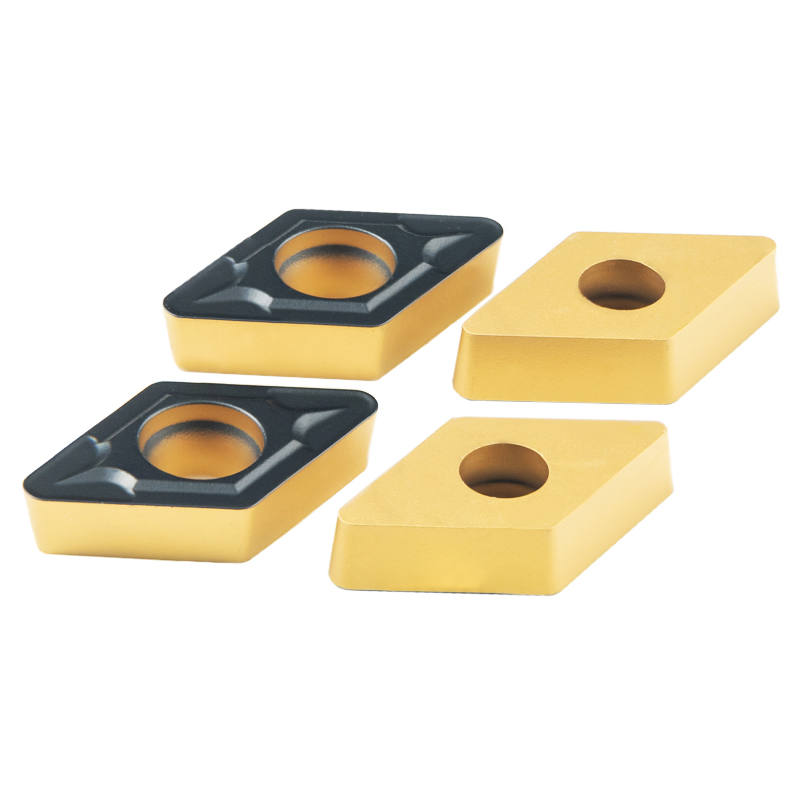

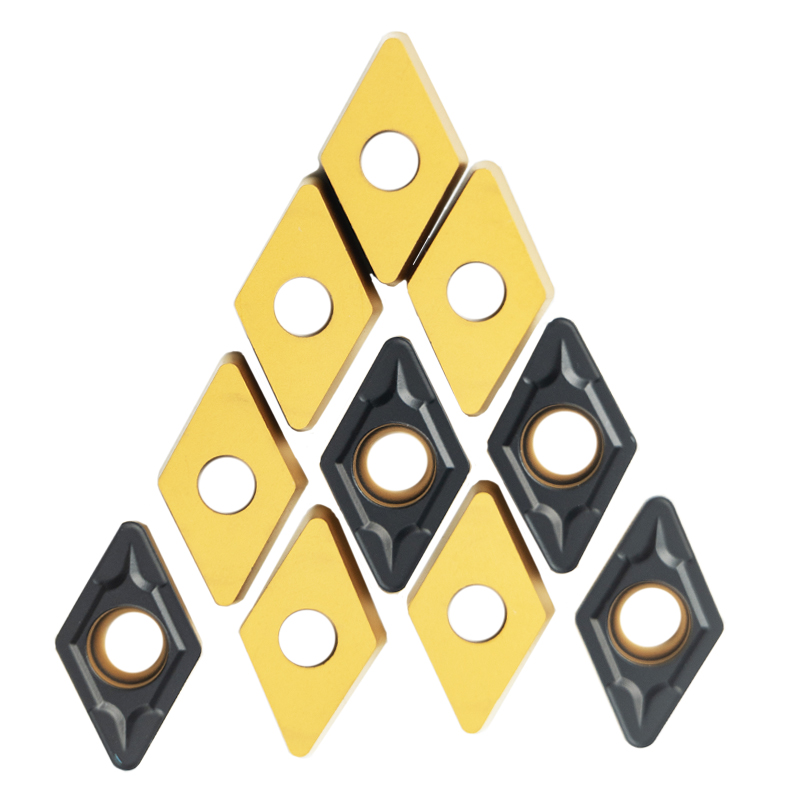

DCMT Carbide Cutting Inserts DCMT070204-MA DCMT070208-MA CNC Lathe Turning Inserts for Steel General machining

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

FAQ

1) Yaushe zan iya samun farashin?

Yawancin lokaci muna magana a cikin sa'o'i 24 bayan mun sami tambayar ku. Idan kuna da gaggawa don samun farashin, da fatan za a kira mu ko ku gaya mana a cikin imel ɗin ku don mu ɗauki fifikon bincikenku.

2) Ta yaya zan iya samun samfurin don duba ingancin ku?

Bayan tabbatar da farashin, zaku iya buƙatar samfuran don bincika ingancin mu. Idan kawai kuna buƙatar samfurin fanko don bincika ƙirar ƙira da ingancin takarda, za mu ba ku samfurin kyauta, muddin kuna iya ɗaukar jigilar kayayyaki.

3) Har yaushe zan iya tsammanin samun samfurin?

Bayan kun biya cajin samfurin kuma aika mana fayilolin da aka tabbatar, samfuran za su kasance a shirye don bayarwa a cikin kwanaki 3-7. Za a aiko muku da samfuran ta hanyar bayyanawa kuma su zo cikin kwanakin aiki 3-7. Kuna iya amfani da asusun ajiyar ku ko ku biya mu kafin lokaci idan ba ku da asusu.

4) Yaya tsawon lokacin da ake aiwatar da dukan aikin?

Bayan kun sanya oda, lokacin sarrafa samarwa shine kimanin kwanaki 20-25. Muna buƙatar kwanaki 7 don shirya duk kayan sannan kwanaki 15 don masana'anta.

5) Me game da sufuri da kwanan watan bayarwa?

Yawancin lokaci muna amfani da jigilar kaya don jigilar kaya. Yana da kusan kwanaki 7-25. Hakanan ya dogara da wane yanki da tashar jiragen ruwa kuke. Zai iya zama ya fi guntu idan kuna buƙatar aika kaya kamar Asiya. Idan akwai wasu abubuwan gaggawa za mu iya aika kayan ta hanyar jirgin sama, muddin kuna da kuɗin zirga-zirga.

6) Shin kai kamfani ne ko masana'anta?

Mu ƙwararrun masana'anta ne. Ba wai kawai mun mallaki masana'antar kayan aikin mu ba, har ma muna da masana'antar siminti ta carbide.

7) Ina ma'aikatar ku take?

Muna cikin garin Zhuzhou na lardin Hunan, garin tungsten carbide na kasar Sin

8) Har yaushe zan iya tsammanin samun samfurin?

Bayan kun biya cajin samfurin kuma aika mana fayilolin da aka tabbatar, samfuran za su kasance a shirye don bayarwa a cikin kwanaki 3-7. Za a aiko muku da samfuran ta hanyar bayyanawa kuma su zo cikin kwanakin aiki 3-5. Kuna iya amfani da asusun ajiyar ku ko ku biya mu kafin lokaci idan ba ku da asusu.

9) Yaya game da hajar ku?

Muna da samfura masu yawa a hannun jari, iri na yau da kullun da girma duk suna cikin haja.

10) Shin yana yiwuwa jigilar kaya kyauta?

Ba mu bayar da sabis na jigilar kaya kyauta. Za mu iya samun rangwame idan kun sayi samfura masu yawa

Jin dadin tuntube ni:

Aimee

Manajan tallace-tallace

Kudin hannun jari Zhuzhou Chuangde Cemented Carbide Co.,Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Gundumar Tianyuan, Birnin Zhuzhou.

Imel: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

WhatsApp/wechat/Skype: 0086 13786352688