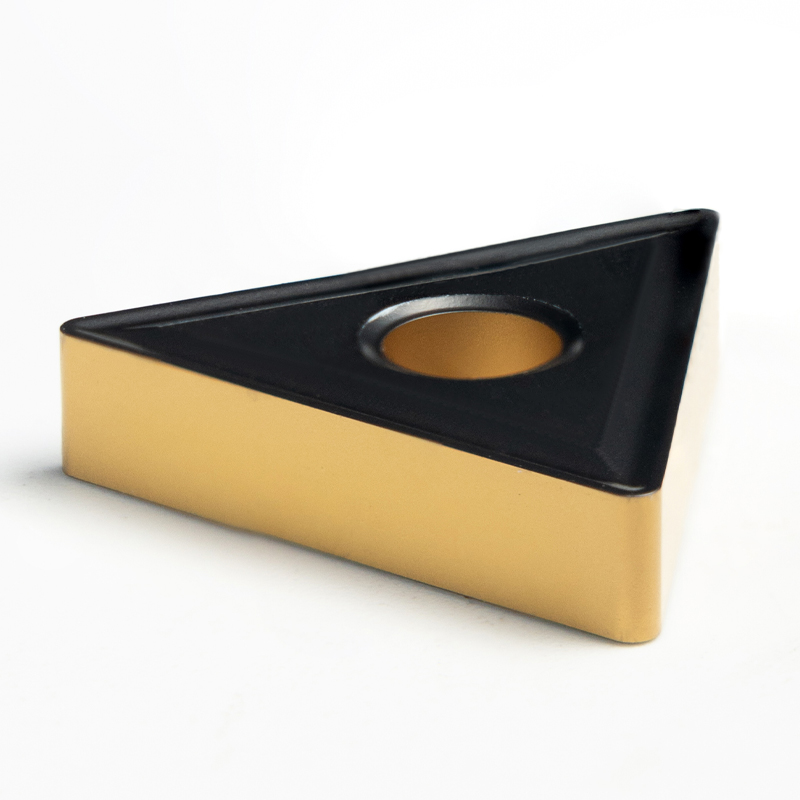

- Grade: CD8125

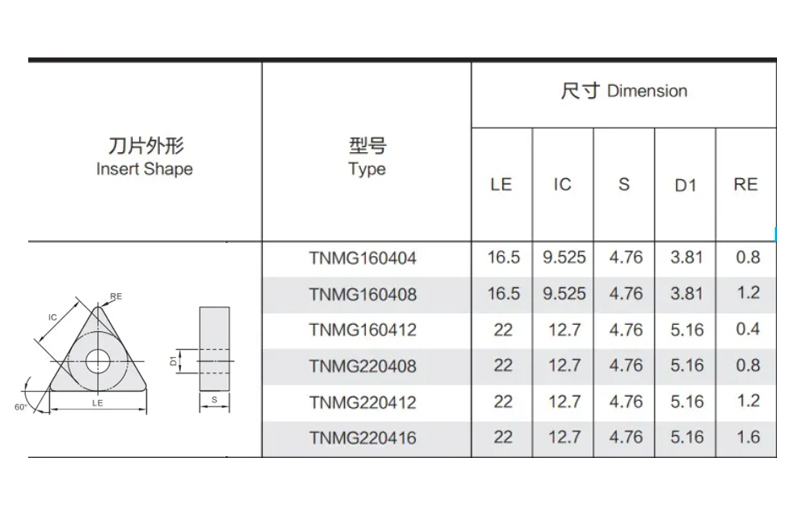

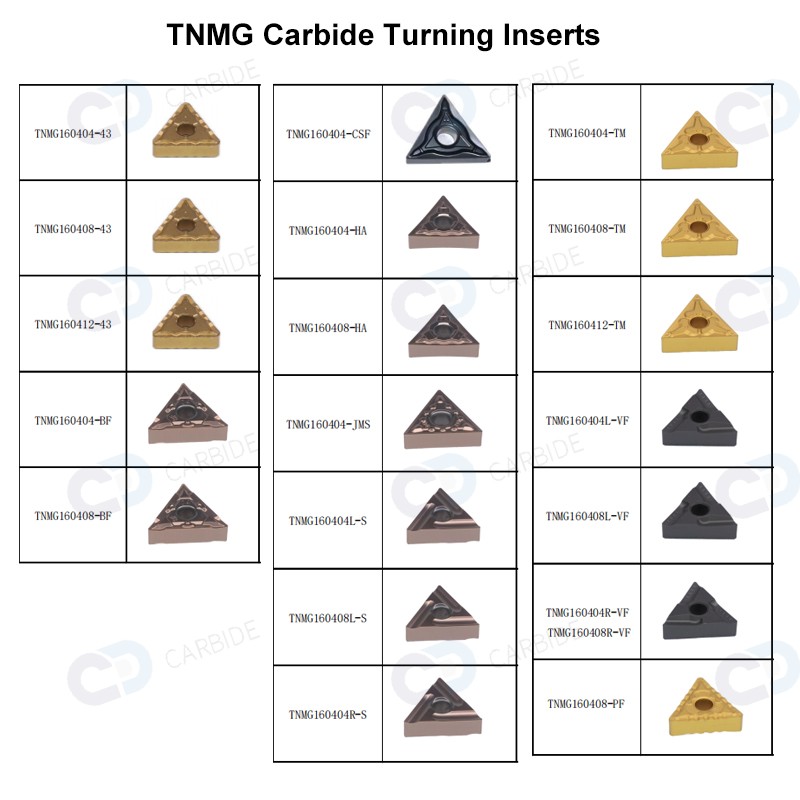

- Model: TNMG220404-TC TNMG220408-TC

- Coating:PVD/CVD

- Application: For the general processing of steel parts

HOIKE

TNMG220404-TC TNMG220408-TC TNMG Carbide cutting tool inserts CNC Lathe Turning Inserts for Steel General machining

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

FAQ

1) I ka manawa hea e hiki ai iaʻu ke loaʻa ke kumukūʻai?

Hoʻopuka pinepine mākou i loko o 24 mau hola ma hope o ka loaʻa ʻana o kāu nīnau.

2) Pehea e hiki ai iaʻu ke loaʻa i kahi laʻana e nānā i kou maikaʻi?

Ma hope o ka hōʻoia ʻana o ke kumukūʻai, hiki iā ʻoe ke koi i nā laʻana e nānā i kā mākou maikaʻi. Inā makemake ʻoe i kahi laʻana hakahaka e nānā i ka hoʻolālā a me ka maikaʻi o ka pepa, e hāʻawi mākou iā ʻoe i kahi laʻana no ka manuahi, ʻoiai ʻoe e hāʻawi i ka ukana hōʻike.

3) Pehea ka lōʻihi e hiki ai iaʻu ke manaʻo e loaʻa ka hāpana?

Ma hope o kou uku ʻana i ka uku hāpana a hoʻouna iā mākou i nā faila i hoʻopaʻa ʻia, e mākaukau nā laʻana no ka lawe ʻana i nā lā 3-7. E hoʻouna ʻia nā laʻana iā ʻoe ma o ka express a hōʻea i nā lā hana 3-7. Hiki iā ʻoe ke hoʻohana i kāu moʻokāki ponoʻī a i ʻole e uku mua iā mākou inā ʻaʻohe āu moʻokāki.

4) Pehea ka lōʻihi o ke kaʻina hana holoʻokoʻa?

Ma hope o kāu kau ʻana i kahi kauoha, ʻo ka manawa hana hana ma kahi o 20-25 mau lā. Pono mākou i nā lā 7 e hoʻomākaukau i nā mea āpau a laila 15 mau lā no ka hana ʻana.

5) Pehea e pili ana i ka lawe ʻana a me ka lā lawe?

Hoʻohana maʻamau mākou i ka hoʻouna ʻana e transprot i ka goods.It ma kahi o 7-25 mau lā. It also denpends on which coutry and port you are.It hiki ke pōkole inā pono ʻoe e hoʻouna i nā waiwai e like me ʻAsia. Inā loaʻa kekahi mau pilikia hiki iā mākou ke hoʻouna aku i nā ukana ma o ka air express, ʻoiai ke loaʻa iā ʻoe ka uku kaʻa.

6) He hui kālepa ʻoe a mea hana paha?

He mea hana 'oihana mākou. ʻAʻole wale mākou i kā mākou hale hana mea hana, akā ua loaʻa pū kekahi hale hana carbide cemented.

7) Aia ma hea kāu hale hana?

Aia mākou ma ke kūlanakauhale ʻo Zhuzhou, ka moku ʻo Hunan., ke kūlanakauhale kumu tungsten carbide o Kina

8) Pehea ka lōʻihi e hiki ai iaʻu ke manaʻo e loaʻa ka hāpana?

Ma hope o kou uku ʻana i ka uku hāpana a hoʻouna iā mākou i nā faila i hoʻopaʻa ʻia, e mākaukau nā laʻana no ka lawe ʻana i nā lā 3-7. E hoʻouna ʻia nā laʻana iā ʻoe ma o ka express a hōʻea i nā lā hana 3-5. Hiki iā ʻoe ke hoʻohana i kāu moʻokāki ponoʻī a i ʻole e uku mua iā mākou inā ʻaʻohe āu moʻokāki.

9) Pehea kāu waiwai?

Loaʻa iā mākou nā huahana nui i loko o ka waihona, nā ʻano maʻamau a me nā nui āpau i ka waihona.

10) Hiki ke hoʻouna manuahi?

ʻAʻole mākou hāʻawi i ka lawelawe hoʻouna manuahi. Hiki iā mākou ke loaʻa ke kumukūʻai inā kūʻai ʻoe i nā huahana nui

E ʻoluʻolu e kelepona mai iaʻu:

Aimee

Luna kuai

ʻO Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

Alanui Taishan, Apana Tianyuan, Kulanakauhale o Zhuzhou.

Leka uila: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688