Dab tsi yog carbide inserts siv rau?

Carbide inserts ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm niaj hnub ua haujlwm thoob plaws ntau yam kev lag luam, vim lawv

tshwj xeeb durability, versatility, thiab precision. Cov inserts no yog siv nyob rau hauv ntau yam ntawm kev txiav thiab shaping

cov txheej txheem, muab cov txiaj ntsig tseem ceeb tshaj li cov cuab yeej siv high-speed steel. Hauv tsab xov xwm no, peb delve rau hauv

cov ntawv thov, qhov zoo, thiab cov ntsiab lus tseem ceeb cuam tshuam nrog carbide inserts.

Taw qhia rau Carbide Inserts:

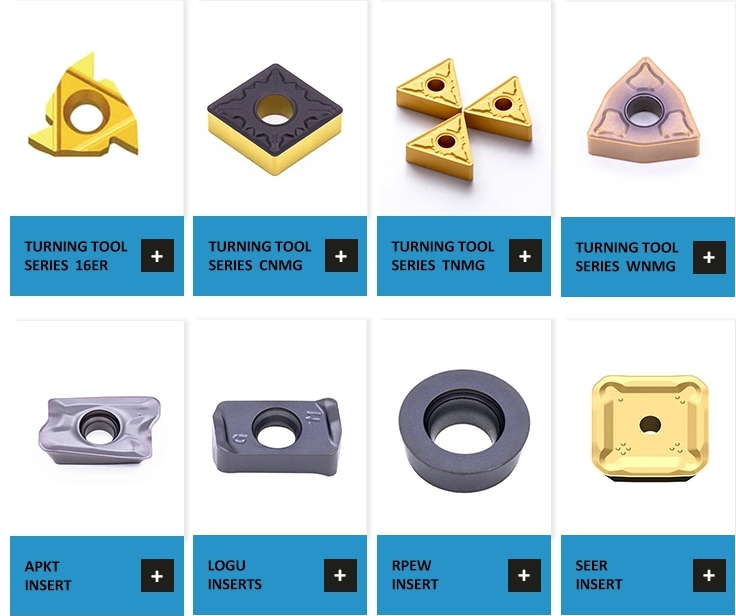

Chuangde yog cov chaw tsim khoom thiab xa khoom ntawm cov cuab yeej carbide thiab lwm yam khoom siv nyob hauv Zhuzhou, Suav. Lub tuam txhab tsim carbide tej cuab yeej siv nyob rau hauv machining thiab metalworking txheej txheem rau hardness thiab hnav tsis kam. Cov no muaj xws li inserts, kawg mills, xyaum, reamers, burr, thiab tshwj xeeb tooling. Nws cov khoom tsim los rau Hlau ua haujlwm.Peb muab cov nqi sib tw thiab cov khoom zoo. Hauv Tshuag, qauv dawb.

Daim ntawv thov:

Carbide inserts dav siv nyob rau hauv cov xov tig, txiav thiab grooving thiab lwm yam. Nws yog ib qho kev xaiv zoo rau roughing, semi-finishing, finishing.general machining steel, stainless hlau thiab cam khwb cia hlau.

1. Tig thiab Milling: Carbide inserts yog siv dav hauv kev xa thiab milling ua haujlwm thoob plaws

ntau yam ntawm cov ntaub ntawv, xws li steel, stainless hlau, cam khwb cia hlau, aluminium, thiab high-temperature alloys.

Lawv ua tau zoo hauv kev tsim cov contours, threads, thiab nto nrog superior nto tiav.

2. Drilling thiab tho txawv: Carbide inserts yog ua hauj lwm nyob rau hauv drilling thiab tho txawv daim ntaub ntawv los tsim lub qhov

sib txawv qhov tob thiab txoj kab uas hla. Lawv siab thermal conductivity thiab tsis kam mus deformation xyuas kom meej

kev ua tau zoo ib yam txawm tias nyob rau hauv kev nyuaj drilling.

3. Xov: Carbide inserts yog nyiam rau kev ua haujlwm threading vim lawv muaj peev xwm tswj tau ntse

txiav cov npoo dhau siv ntev, ua rau cov xov raug raug thiab txo cov cuab yeej hnav.

4. Grooving thiab Parting: Carbide inserts pab txhawb kev ua haujlwm zoo grooving thiab parting, ua kom lub

creation ntawm nqaim raws thiab kev sib cais ntawm workpieces nrog tsawg kawg nkaus cov khoom wastage.

5. High-Speed Machining (HSM): Carbide inserts yog indispensable nyob rau hauv HSM daim ntaub ntawv uas ceev cov ntaub ntawv.

cov nqi tshem tawm yog qhov tseem ceeb. Lawv superior hardness thiab thermal stability pab txhawb kev txiav ceev

thiab pub tus nqi, txhim kho productivity thiab nqi-effectiveness.

Qhov zoo:

1. Extended Tool Life: Carbide inserts nthuav dav lub cuab tam lub neej ntev dua piv rau cov pa high-speed.

cov cuab yeej steel, txo cov cuab yeej hloov pauv thiab poob qis.

2. Txhim kho Productivity: Qhov kev ua tau zoo tshaj plaws thiab hnav tsis kam ntawm carbide inserts ua rau

ceev machining speeds thiab nce throughput, txhim khu tag nrho productivity.

3. Txhim kho nto tiav: Carbide inserts tsim smoother nto tiav nrog tsawg burrs thiab tsis xws luag,

tshem tawm qhov xav tau rau kev ua haujlwm tiav thib ob thiab txhim kho qhov zoo.

4. Versatility: Carbide inserts muaj nyob rau hauv ntau yam geometries, coatings, thiab qib tailored rau

tshwj xeeb machining daim ntaub ntawv, muab versatility thiab yooj nyob rau hauv cov cuab yeej xaiv.

5. Kev Txuag Nqi: Txawm tias lawv cov nqi pib ntau dua, carbide inserts xa cov nqi zoo dua rau lawv

lifespan vim txo cov nqi siv hluav taws xob, txhim kho cov khoom tsim tau, thiab cov nqi qis dua ib feem machining.

Hauv kev xaus, carbide inserts sawv cev rau lub hauv paus ntawm cov cuab yeej siv niaj hnub no, muab kev ua haujlwm tsis sib xws, kev siv ntau yam, thiab kev ua haujlwm raug nqi thoob plaws ntau hom kev siv.