- Grade: CD8125

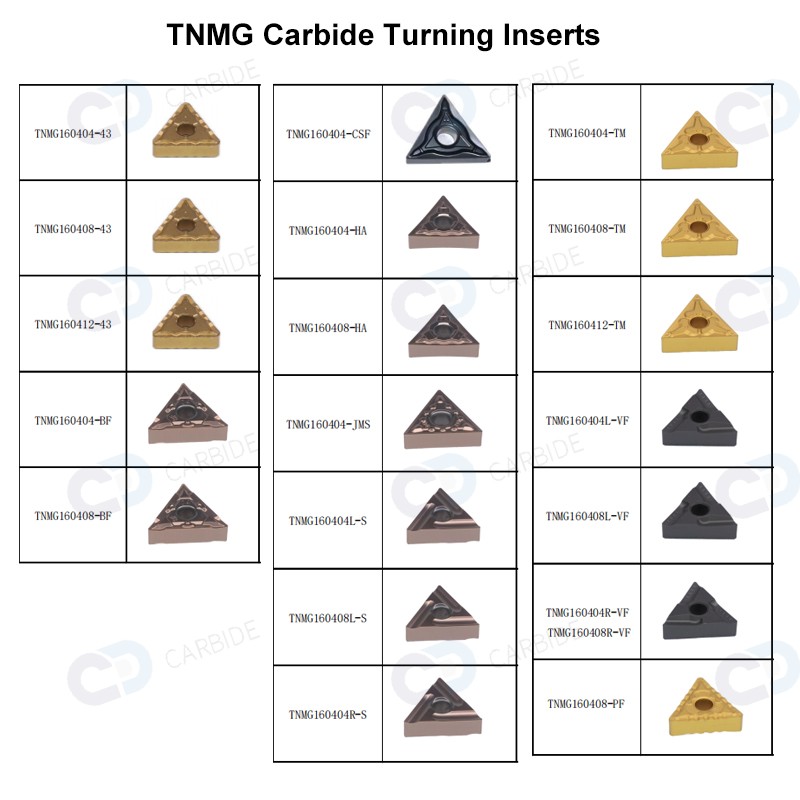

- Model: TNMG220404-TC TNMG220408-TC

- Coating:PVD/CVD

- Application: For the general processing of steel parts

Kev piav qhia

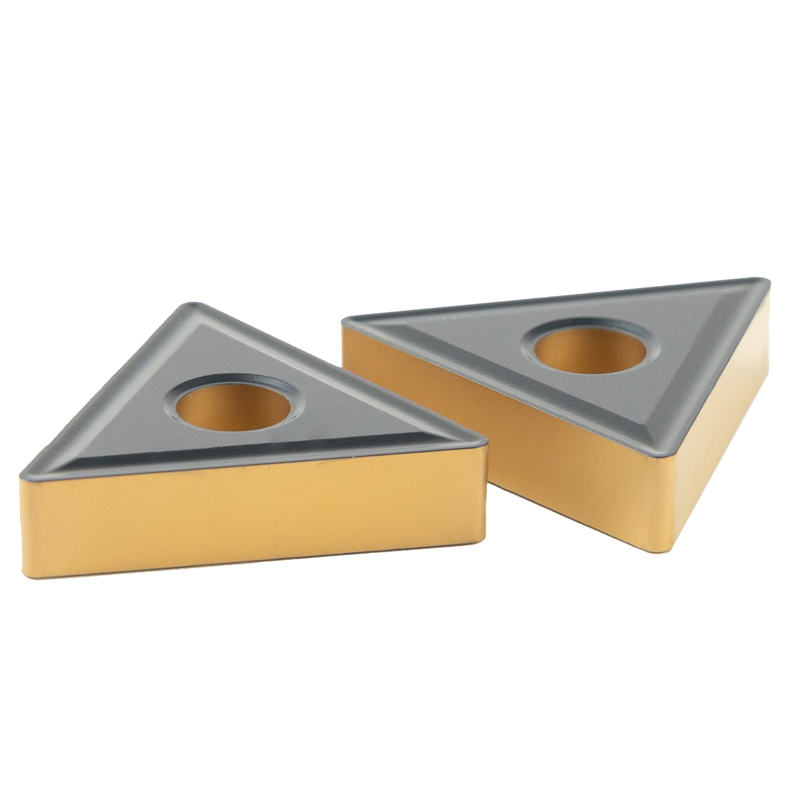

CNC Turning Tools TNMG220404-TC TNMG220408-TC TNMG Carbide cutting inserts for Lathe

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

FAQ

1) Thaum twg kuv tuaj yeem tau txais tus nqi?

Peb feem ntau hais tsis pub dhau 24 teev tom qab peb tau txais koj qhov kev nug.Yog tias koj ceev heev kom tau txais tus nqi, thov hu rau peb los yog qhia rau peb hauv koj tus email kom peb yuav suav txog koj qhov kev nug tseem ceeb.

2) Kuv tuaj yeem tau txais tus qauv los kuaj xyuas koj li cas?

Tom qab tus nqi lees paub, koj tuaj yeem xav tau cov qauv los kuaj xyuas peb qhov zoo. Yog tias koj tsuas yog xav tau ib qho qauv dawb los kuaj xyuas tus qauv tsim thiab ntawv zoo, peb yuav muab cov qauv dawb rau koj, tsuav yog koj them tus nqi thauj khoom.

3) Kuv tuaj yeem cia siab tias yuav tau txais tus qauv ntev npaum li cas?

Tom qab koj them tus nqi coj mus kuaj thiab xa peb cov ntaub ntawv lees paub, cov qauv yuav npaj rau kev xa khoom hauv 3-7 hnub. Cov qauv yuav raug xa tuaj rau koj ntawm kev nthuav qhia thiab tuaj txog hauv 3-7 hnub ua haujlwm. Koj tuaj yeem siv koj tus kheej tus account lossis them nyiaj ua ntej yog tias koj tsis muaj tus account.

4) Ntev npaum li cas tag nrho cov txheej txheem tau ua tiav?

Tom qab koj tso qhov kev txiav txim, lub sijhawm ua haujlwm yog li 20-25 hnub. Peb xav tau 7 hnub los npaj tag nrho cov khoom ces 15 hnub rau kev tsim khoom.

5) Yuav ua li cas txog hnub thauj thiab xa khoom?

Feem ntau peb siv cov khoom xa tuaj rau transprot cov khoom.Nws yog li ntawm 7-25 hnub.Nws kuj denpends ntawm qhov twg coutry thiab chaw nres nkoj koj nyob.Nws yuav luv dua yog tias koj xav tau xa cov khoom xws li Neeg Esxias. Yog tias muaj qee qhov xwm txheej peb tuaj yeem xa cov khoom ntawm huab cua nthuav qhia, tsuav yog koj them cov nqi tsheb thauj mus los.

6) Puas yog koj lub tuam txhab lag luam lossis tus tsim khoom?

Peb yog cov chaw tsim khoom tshaj lij. Peb tsis tsuas yog muaj peb lub Hoobkas cov cuab yeej, tab sis kuj muaj cov cemented carbide Hoobkas.

7) Koj lub Hoobkas nyob qhov twg?

Peb nyob hauv Zhuzhou nroog, Hunan Province ., tungsten carbide puag lub nroog ntawm Tuam Tshoj

8) Kuv tuaj yeem cia siab tias yuav tau txais tus qauv ntev npaum li cas?

Tom qab koj them tus nqi coj mus kuaj thiab xa peb cov ntaub ntawv lees paub, cov qauv yuav npaj rau kev xa khoom hauv 3-7 hnub. Cov qauv yuav raug xa tuaj rau koj ntawm kev nthuav qhia thiab tuaj txog hauv 3-5 hnub ua haujlwm. Koj tuaj yeem siv koj tus kheej tus account lossis them nyiaj ua ntej yog tias koj tsis muaj tus account.

9) Yuav ua li cas txog koj cov khoom?

Peb muaj cov khoom lag luam ntau hauv Tshuag, hom tsis tu ncua thiab qhov ntau thiab tsawg yog txhua yam hauv Tshuag.

10) Puas muaj kev xa khoom dawb?

Peb tsis muaj kev pabcuam shipping dawb. Peb tuaj yeem muaj luv nqi yog tias koj yuav cov khoom lag luam ntau

Xav tias dawb hu rau kuv:

Aimee

Tus neeg muag khoom

Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

Taishan Road, Tianyuan District, Zhuzhou City.

Email: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

whatspp/wechat/Skype: 0086 13786352688