404 Yuam Kev

- Lub tsev

- |- Hais txog peb

- |- Cov khoom

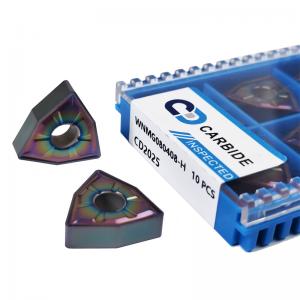

- |-- Tig Inserts cuab yeej

- |--- Tig cov cuab yeej rau Steel Processing

- |--- Tig cov cuab yeej rau Stainless hlau ua

- |--- Tig cov cuab yeej rau Cast Iron Processing

- |--- Drilling Inserts

- |--- Tig cov cuab yeej rau Aluminium Ua

- |--- CBN & PCD Inserts

- |--- Cermet Inserts

- |--- CNC Tool Holder

- |--- Original Inserts

- |-- Khoom Carbide End Mills

- |--- Woodworking txiav cov cuab yeej

- |--- 2/4 Corner Radius End Mills

- |--- 2/4 Flutes Ball Nose End Mills

- |--- 2/4 Flutes Flat End Mills

- |--- HRC55 Square End mills rau Txiav

- |--- Roughing End Mills

- |--- Chamfer kawg zeb

- |--- Khoom Carbide Drills

- |--- Carbide Reamers

- |-- Cermet End Mill

- |- Download tau

- |-- Pab ntaub ntawv

- |-- ntaub ntawv download

- |- Xov xwm

- |-- Tuam txhab tshiab

- |--- Department of xov xwm

- |-- Xov xwm kev lag luam

- |- Duab

- |-- Cov neeg ua haujlwm yees duab album

- |-- Cov neeg siv khoom

- |- Tiv tauj peb