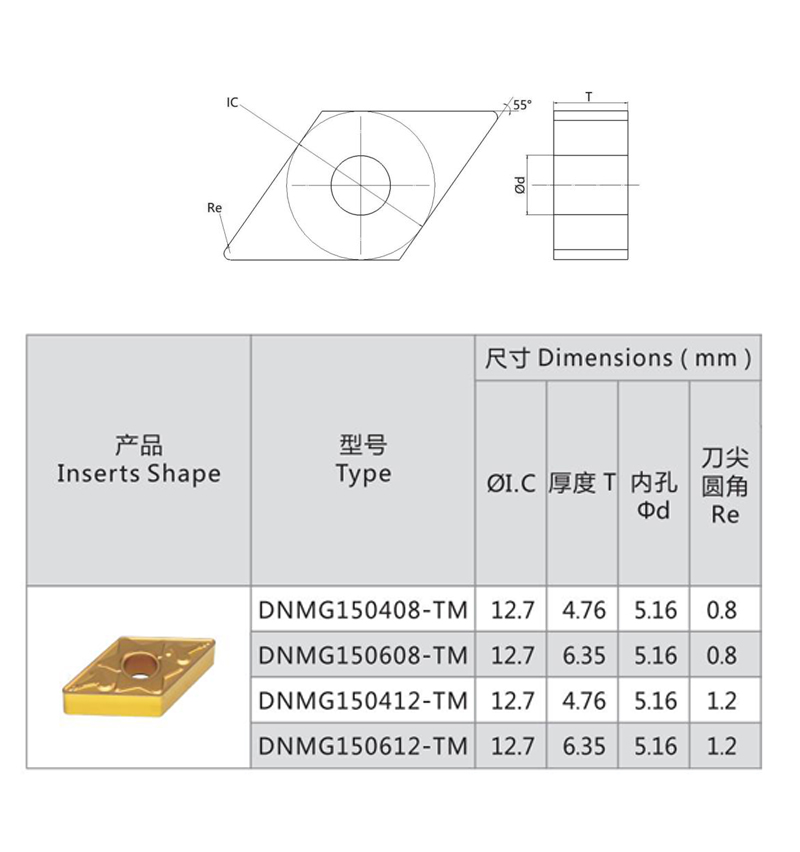

- Grade: CD8125

- Model: DNMG150608-TM DNMG150612-TM

- Application: CNC Lathe Machine

- Cutting Condition: High Precision Finishing Cutting

OPIS

DNMG Carbide Cutting Inserts DNMG150608-TM DNMG150612-TM CNC Lathe Turning Inserts for Steel General machining

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

Pitanja

1) Kada mogu dobiti cijenu?

Obično nudimo ponudu u roku od 24 sata nakon što dobijemo vaš upit. Ako ste vrlo hitni da dobijete cijenu, nazovite nas ili nam recite u svojoj e-pošti kako bismo razmotrili prioritet vašeg upita.

2) Kako mogu dobiti uzorak za provjeru vaše kvalitete?

Nakon potvrde cijene, možete zatražiti uzorke kako biste provjerili našu kvalitetu. Ako vam je potreban samo prazan uzorak za provjeru dizajna i kvalitete papira, mi ćemo vam dati uzorak besplatno, sve dok si priuštite ekspresni teret.

3) Koliko dugo mogu očekivati da ću dobiti uzorak?

Nakon što platite cijenu uzorka i pošaljete nam potvrđene datoteke, uzorci će biti spremni za isporuku za 3-7 dana. Uzorci će vam biti poslani ekspresno i stići za 3-7 radnih dana. Možete koristiti svoj brzi račun ili nam platiti unaprijed ako nemate račun.

4) Koliko dugo se cijeli postupak razrađuje?

Nakon što naručite, vrijeme obrade je oko 20-25 dana. Potrebno nam je 7 dana za pripremu svih materijala, a zatim 15 dana za proizvodnju.

5) Što je s datumom prijevoza i isporuke?

Obično koristimo pošiljku za prijenos robe. To je oko 7-25 dana. Također ovisi o tome u kojoj se zemlji i luci nalazite. Može biti kraće ako trebate poslati robu poput azijske. Ako postoje hitni slučajevi, robu možemo poslati zračnim putem, sve dok si priuštite troškove prometa.

6) Jeste li trgovačko poduzeće ili proizvođač?

Mi smo profesionalni proizvođač. Ne samo da posjedujemo našu tvornicu alata, već imamo i tvornicu cementnog karbida.

7) Gdje se nalazi vaša tvornica?

Nalazimo se u gradu Zhuzhou, provinciji Hunan., gradu na bazi volfram karbida u Kini

8) Koliko dugo mogu očekivati da dobijem uzorak?

Nakon što platite cijenu uzorka i pošaljete nam potvrđene datoteke, uzorci će biti spremni za isporuku za 3-7 dana. Uzorci će vam biti poslani ekspresno i stići za 3-5 radnih dana. Možete koristiti svoj brzi račun ili nam platiti unaprijed ako nemate račun.

9) Što je s vašim zalihama?

Imamo velike količine proizvoda na lageru, uobičajene vrste i veličine su na zalihama.

10) Je li moguća besplatna dostava?

Ne nudimo uslugu besplatne dostave. Možemo imati popust ako kupite veliku količinu proizvoda

Slobodno me kontaktiraj :

Aimee

Voditelj prodaje

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Okrug Tianyuan, Grad Zhuzhou.

E-pošta: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688