- Grade: CD7225

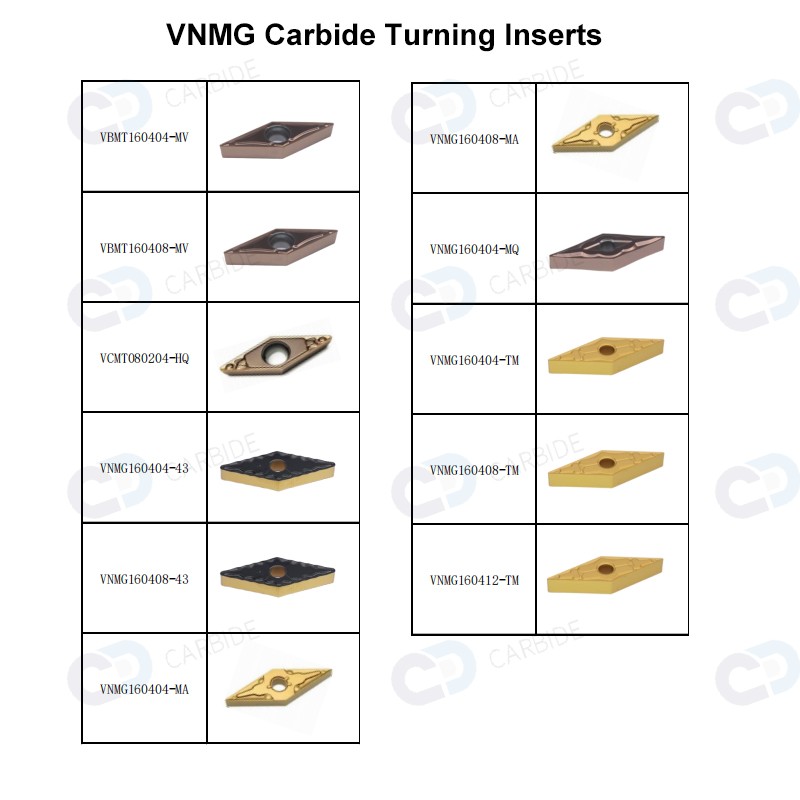

- Model: VNMG160404-MA VNMG160408-MA

- Application: CNC Lathe Machine

- Cutting Condition: High Precision Finishing Cutting

Nkọwa

Cemented tungsten carbide turning insert VNMG160404-MA VNMG160408-MA for CNC steel Machine

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

FAQ

1) Kedu mgbe m nwere ike nweta ọnụahịa ahụ?

Anyị na-ehotakarị n'ime awa 24 mgbe anyị nwetasịrị ajụjụ gị. Ọ bụrụ na ị dị ngwa ngwa iji nweta ọnụahịa ahụ, biko kpọọ anyị ma ọ bụ gwa anyị na email gị ka anyị wee leba anya na ajụjụ gị dị mkpa.

2) Kedu ka m ga-esi nweta sample iji lelee ogo gị?

Mgbe nkwenye ọnụahịa gasịrị, ị nwere ike ịchọ maka nlele iji lelee àgwà anyị. Ọ bụrụ na ịchọrọ naanị nlele oghere iji lelee imewe na ịdị mma akwụkwọ, anyị ga-enye gị nlele n'efu, ọ bụrụhaala na ị na-enweta ibu awara awara.

3) Ogologo oge ole ka m ga-atụ anya inweta sample?

Mgbe ịkwụchara ụgwọ nlele ma ziga anyị faịlụ ndị enwetara, ihe nlele ahụ ga-adị njikere maka nnyefe na ụbọchị 3-7. A ga-ezigara gị ihe nlele ahụ site na ngwa ngwa wee bịarute n'ime ụbọchị ọrụ 3-7. Ị nwere ike iji akaụntụ awara awara nke gị ma ọ bụ kwụọ anyị ụgwọ ma ọ bụrụ na ịnweghị akaụntụ.

4) Ogologo oge ole ka a na-arụ ọrụ ahụ dum?

Mgbe ị nyechara iwu, oge njikwa mmepụta ihe dị ka ụbọchị 20-25. Anyị chọrọ ụbọchị 7 iji dozie ihe niile wee 15 ụbọchị maka nrụpụta.

5) Kedu maka ụbọchị njem na nnyefe?

Dị ka ọ na-adịkarị, anyị na-eji mbupu na-ebufe ngwongwo ndị ahụ. Ọ bụ ihe dị ka ụbọchị 7-25. Ọ na-adaberekwa na ọdụ ụgbọ mmiri na ọdụ ụgbọ mmiri ị nọ. Ọ nwere ike ịdị mkpụmkpụ ma ọ bụrụ na ịchọrọ iziga ngwaahịa dị ka Asia. Ọ bụrụ na enwere ụfọdụ ihe mberede, anyị nwere ike izipu ngwongwo ndị ahụ site na ikuku ikuku, ọ bụrụhaala na ị na-akwụ ụgwọ ụgwọ okporo ụzọ.

6) Ị bụ ụlọ ọrụ azụmaahịa ma ọ bụ onye nrụpụta?

Anyị bụ ndị nrụpụta ọkachamara. Ọ bụghị naanị na anyị nwere ụlọ ọrụ akụrụngwa anyị, mana anyị nwekwara ụlọ ọrụ carbide cimented.

7) Ebee ka ụlọ ọrụ mmepụta ihe gị dị?

Anyị dị na Zhuzhou obodo, Hunan Province., Tungsten carbide isi obodo China.

8) Ogologo oge ole ka m ga-atụ anya inweta sample?

Mgbe ịkwụchara ụgwọ nlele ma ziga anyị faịlụ ndị enwetara, ihe nlele ahụ ga-adị njikere maka nnyefe na ụbọchị 3-7. A ga-ezigara gị ihe nlele ahụ site na ngwa ngwa wee bịarute n'ime ụbọchị ọrụ 3-5. Ị nwere ike iji akaụntụ awara awara nke gị ma ọ bụ kwụọ anyị ụgwọ ma ọ bụrụ na ịnweghị akaụntụ.

9) Kedu maka ngwaahịa gị?

Anyị nwere nnukwu ngwaahịa ngwaahịa na ngwaahịa, ụdị oge niile na nha niile dị na ngwaahịa.

10) Enwere ike mbupu n'efu?

Anyị anaghị enye ọrụ mbupu n'efu. Anyị nwere ike ịnwe mbelata ma ọ bụrụ na ịzụtara nnukwu ngwaahịa

Enwere onwe gị ịkpọtụrụ m:

Aimee

Onye njikwa ịre ahịa

Ụgwọ nke ụlọ ọrụ Zhuzhou Chuangde Cemented Carbide Co., Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrikti, City Zhuzhou .

Email: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

WhatsApp/wechat/Skype: 0086 13786352688