404 Njehie

- Ulo

- |- Gbasara anyị

- |- Ngwaahịa

- |-- Ngwa mgbakwunye na-atụgharị

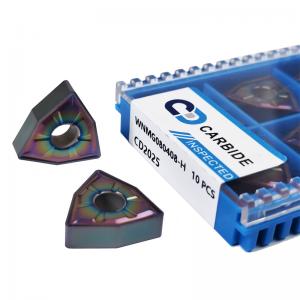

- |--- Ngwa ntụgharị maka Nhazi igwe

- |--- Ngwa ntụgharị maka nhazi igwe anaghị agba nchara

- |--- Ngwa ntụgharị maka Nhazi nke igwe nkedo

- |--- Ihe ntinye egwu egwu

- |--- Ngwa ntụgharị maka Nhazi Aluminom

- |--- Ihe ntinye CBN na PCD

- |--- Ntinye Cermet

- |--- Ihe njide Ngwá Ọrụ CNC

- |--- Ntinye izizi

- |-- Mills Ọgwụgwụ Carbide siri ike

- |--- Ngwa osisi na-egbutu

- |--- 2/4 Nkuku Radius Ọgwụgwụ Mills

- |--- 2/4 Ọjà Igwe Ọgwụgwụ bọọlụ

- |--- 2/4 Ọjà Flat End Mills

- |--- HRC55 Square End igwe ihe igwe maka ịkpụ

- |--- Roughing End Mills

- |--- Ụlọ ihe nkiri Chamfer

- |--- Mgbochi Carbide siri ike

- |--- Ndị na-ahụ maka Carbide Reamers

- |-- Cermet End Mill

- |- Budata

- |-- Akwụkwọ enyemaka

- |-- nbudata faịlụ

- |- Akụkọ

- |-- Ụlọ ọrụ ọhụrụ

- |--- Ngalaba ozi

- |-- Akụkọ ụlọ ọrụ

- |- Foto

- |-- Album foto onye ọrụ

- |-- Ikpe ndị ahịa

- |- Kpọtụrụ anyị