- Grade: CD7225

- Model: DCMT070208-MV

- Application: CNC Lathe Machine

- Cutting Condition: High Precision Finishing Cutting

DESKRIPSI

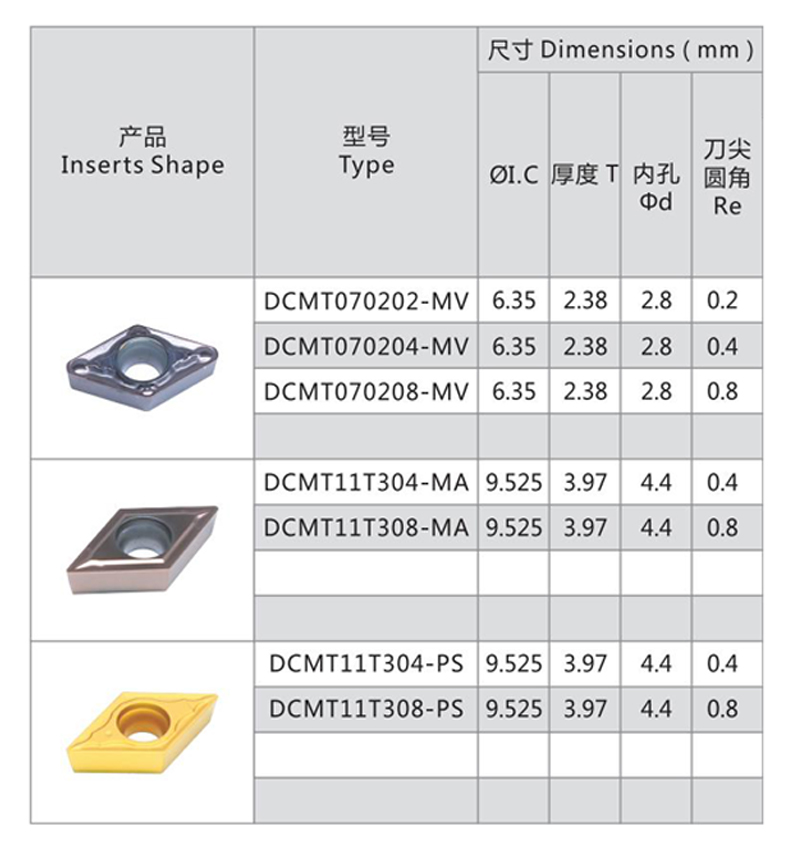

DCMT070204-MV DCMT070208-MV CNC Carbide Turning Inserts Manufacturer Turning Inserts Lathe Carbide Inserts for Steel and Stainless Steel

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

FAQ

1) Nalika aku bisa njaluk rega?

Kita biasane ngutip sajrone 24 jam sawise njaluk pitakon sampeyan.

2) Kepiye carane njaluk sampel kanggo mriksa kualitas sampeyan?

Sawise konfirmasi rega, sampeyan bisa njaluk conto kanggo mriksa kualitas kita. Yen sampeyan mung butuh sampel kosong kanggo mriksa desain lan kualitas kertas, kita bakal menehi conto gratis, anggere sampeyan bisa mbayar pengiriman ekspres.

3) Suwene aku bisa nyana kanggo njaluk sampel?

Sawise sampeyan mbayar biaya sampel lan ngirim file dikonfirmasi, conto bakal siap kanggo pangiriman ing 3-7 dina. Sampel bakal dikirim menyang sampeyan liwat ekspres lan teka ing 3-7 dina kerja. Sampeyan bisa nggunakake akun ekspres dhewe utawa prabayar yen sampeyan ora duwe akun.

4) Suwene suwene kabeh prosedur ditindakake?

Sawise sampeyan nggawe pesenan, wektu penanganan produksi kira-kira 20-25 dina. Kita butuh 7 dina kanggo nyiapake kabeh barang banjur 15 dina kanggo manufaktur.

5) Apa babagan transportasi lan tanggal pangiriman?

Biasane kita nggunakake kiriman kanggo transprot barang. Iku bab 7-25 dina. Iku uga denpends kang coutry lan port sampeyan.Bisa dadi luwih cendhek yen sampeyan kudu ngirim barang kaya Asia. Yen ana sawetara kahanan darurat, kita bisa ngirim barang liwat ekspres udara, anggere sampeyan bisa mbayar biaya lalu lintas.

6) Apa sampeyan perusahaan dagang utawa pabrikan?

Kita minangka produsen profesional. Kita ora mung duwe pabrik alat, nanging uga duwe pabrik karbida semen.

7) Where is pabrik Panjenengan?

Kita dumunung ing kutha Zhuzhou, Provinsi Hunan., Kutha basis tungsten karbida China

8) Suwene aku bisa nyana kanggo njaluk sampel?

Sawise sampeyan mbayar biaya sampel lan ngirim file dikonfirmasi, conto bakal siap kanggo pangiriman ing 3-7 dina. Sampel bakal dikirim menyang sampeyan liwat ekspres lan teka ing 3-5 dina kerja. Sampeyan bisa nggunakake akun ekspres dhewe utawa prabayar yen sampeyan ora duwe akun.

9) Kepiye babagan saham sampeyan?

We duwe produk jumlahe akeh ing Simpenan, jinis biasa lan ukuran kabeh ing Simpenan.

10) Apa pengiriman gratis bisa?

Kita ora nawakake layanan pengiriman gratis. Kita bisa duwe diskon yen sampeyan tuku produk jumlahe akeh

Bebas bae kanggo hubungi kula:

Aimee

Manajer sales

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrik, Zhuzhou City.

Email: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688