- Grade: CD8125

- Coating:PVD

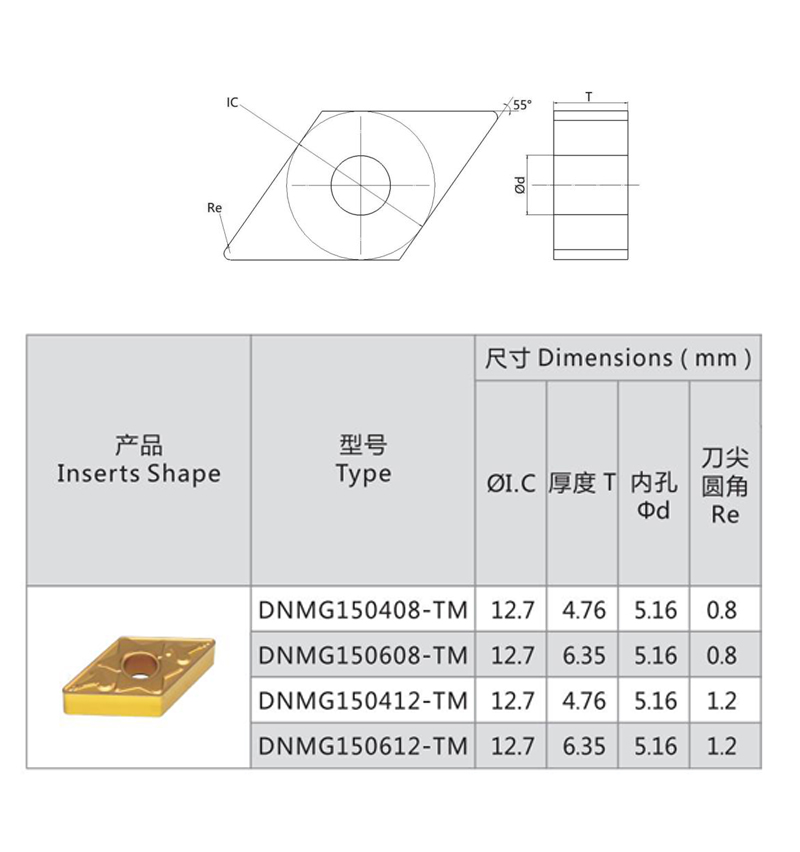

- Model: DNMG150608-TM DNMG150612-TM

- Application: For the general processing of steel parts

WHAKAMAHI

DNMG Carbide Cutting Inserts DNMG150608-TM DNMG150612-TM CNC Lathe Turning Inserts for Steel General machining

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

FAQ

1) Ahea e taea ai e au te utu?

I te nuinga o nga wa ka korero matou i roto i nga haora 24 i muri i to maatau patai.Mehemea kei te tino akiaki koe ki te tiki i te utu, waea mai ki a maatau, korero mai ranei i to imeera kia whai whakaaro ai matou ki to patai.

2) Me pehea e taea ai e au he tauira hei tirotiro i to kounga?

I muri i te haamauraa utu, ka taea e koe te tono mo nga tauira hei tirotiro i to maatau kounga. Mena ka hiahia noa koe ki tetahi tauira waatea hei tirotiro i te hoahoa me te kounga o te pepa, ka tukuna atu e matou he tauira mo te kore utu, i te mea ka taea e koe te utu mo te utu utu.

3) Kia pehea te roa ka tumanako ahau ki te tiki i te tauira?

I muri i to utu i te utu tauira me te tuku mai i nga konae kua whakamanahia, ka rite nga tauira mo te tuku i nga ra 3-7. Ka tukuna atu nga tauira ki a koe ma te korero ka tae mai i nga ra mahi 3-7. Ka taea e koe te whakamahi i to ake putea korero, utu tomua ranei ki a maatau mena kaore he putea.

4) Kia pehea te roa o te mahi katoa?

I muri i to tuunga ota, ko te waa whakahaere mo te 20-25 ra. Me 7 nga ra ki te whakarite i nga mea katoa ka 15 nga ra mo te hanga.

5) He aha te waa kawe me te ra tuku?

Ko te tikanga ka whakamahia e matou he tuku ki te whakawhiti i nga taonga. Ko te 7-25 nga ra. Ka whakawhirinaki ano ki tehea whenua me te tauranga kei a koe. He poto ake mena ka hiahia koe ki te tuku i nga taonga penei i a Ahia. Mena he ohorere ka taea e matou te tuku i nga taonga ma te rererangi rererangi, mena ka utua e koe nga utu hokohoko.

6) He kamupene hokohoko koe, he kaihanga ranei?

He kaihanga ngaio matou. Ehara i te mea kei a matou anake o maatau wheketere taputapu, engari he wheketere carbide cimented hoki.

7) Kei hea to wheketere?

Kei roto matou i te taone nui o Zhuzhou, te Porowini o Hunan., te taone nui o Haina

8) Kia pehea te roa ka tumanako ahau ki te tiki i te tauira?

I muri i to utu i te utu tauira me te tuku mai i nga konae kua whakamanahia, ka rite nga tauira mo te tuku i nga ra 3-7. Ka tukuna atu nga tauira ki a koe ma te korero ka tae mai i nga ra mahi 3-5. Ka taea e koe te whakamahi i to ake putea korero, utu tomua ranei ki a maatau mena kaore he putea.

9) Me pehea to taonga?

He maha nga hua kei roto i nga taonga, ko nga momo me nga rahi kei roto katoa.

10) Ka taea te tuku kore utu?

Kaore matou e tuku ratonga kaipuke kore utu. Ka taea e taatau te utu mena ka hoko koe i nga hua nui

Tena koa whakapiri mai ki ahau:

Aimee

Kaiwhakahaere hokohoko

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Īmēra: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688