- Grade: CD7225

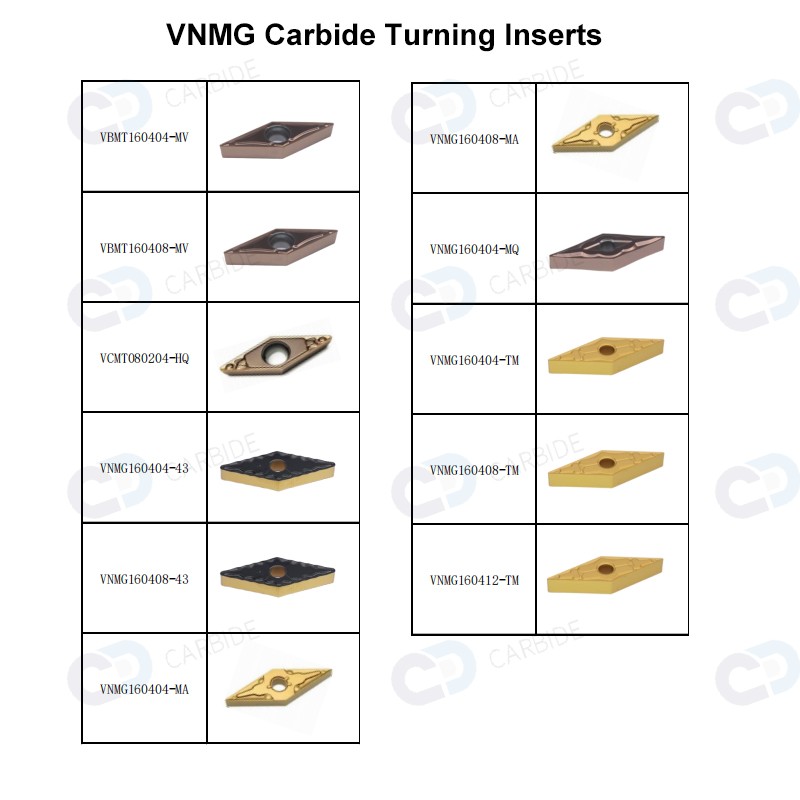

- Model: VNMG160404-MA VNMG160408-MA

- Application: CNC Lathe Machine

- Cutting Condition: High Precision Finishing Cutting

DESKRIZZJONI

Cemented tungsten carbide turning insert VNMG160404-MA VNMG160408-MA for CNC steel Machine

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

FAQ

1) Meta nista 'nikseb il-prezz?

Normalment nikkwotaw fi żmien 24 siegħa wara li nġibu l-inkjesta tiegħek. Jekk int urġenti ħafna biex tikseb il-prezz, jekk jogħġbok ċempelna jew għidilna fl-email tiegħek sabiex inqisu l-prijorità tal-inkjesta tiegħek.

2) Kif nista 'nikseb kampjun biex niċċekkja l-kwalità tiegħek?

Wara l-konferma tal-prezz, tista 'teħtieġ li l-kampjuni jiċċekkjaw il-kwalità tagħna. Jekk għandek bżonn biss kampjun vojt biex tiċċekkja d-disinn u l-kwalità tal-karta, aħna nipprovdulek kampjun b'xejn, sakemm taffordja l-merkanzija espressa.

3) Kemm nista' nistenna li nikseb il-kampjun?

Wara li tħallas il-ħlas tal-kampjun u tibgħatilna fajls ikkonfermati, il-kampjuni jkunu lesti għall-kunsinna fi żmien 3-7 ijiem. Il-kampjuni jintbagħtulek permezz express u jaslu fi 3-7 ijiem tax-xogħol. Tista' tuża l-kont espress tiegħek stess jew tħallasna minn qabel jekk ma jkollokx kont.

4) Kemm idum il-proċedura kollha li qed tinħadem?

Wara li tagħmel ordni, il-ħin tal-immaniġġjar tal-produzzjoni huwa ta 'madwar 20-25 jum. Għandna bżonn 7 ijiem biex nippreparaw l-għalf kollu imbagħad 15-il jum għall-manifattura.

5) Xi ngħidu dwar it-trasport u d-data tal-kunsinna?

Normalment nużaw il-vjaġġ bil-baħar biex jittrasportaw il-merkanzija. Huwa ta 'madwar 7-25 ġurnata. Jiddependi wkoll minn liema pajjiż u port int. Jista' jkun iqsar jekk għandek bżonn tibgħat l-oġġetti bħall-Asja. Jekk ikun hemm xi emerġenzi nistgħu nibagħtu l-merkanzija permezz ta 'air express, sakemm taffordja l-ispiża tat-traffiku.

6) Int kumpanija kummerċjali jew manifattur?

Aħna manifattur professjonali. Aħna mhux biss tippossjedi l-fabbrika tal-għodod tagħna, iżda għandna wkoll fabbrika tal-karbur tas-siment.

7) Fejn tinsab il-fabbrika tiegħek?

Aħna jinsabu fil-belt ta 'Zhuzhou, Provinċja ta' Hunan., belt bażi tal-karbur tat-tungstenu taċ-Ċina

8) Kemm nista' nistenna li nikseb il-kampjun?

Wara li tħallas il-ħlas tal-kampjun u tibgħatilna fajls ikkonfermati, il-kampjuni jkunu lesti għall-kunsinna fi żmien 3-7 ijiem. Il-kampjuni jintbagħtulek permezz express u jaslu fi 3-5 ijiem tax-xogħol. Tista' tuża l-kont espress tiegħek stess jew tħallasna minn qabel jekk ma jkollokx kont.

9) Kif dwar l-istokk tiegħek?

Għandna prodotti ta 'kwantità kbira fl-istokk, tipi u daqsijiet regolari huma kollha fl-istokk.

10) Huwa possibbli tbaħħir b'xejn?

Aħna ma noffrux servizz ta 'tbaħħir b'xejn. Nistgħu jkollna skont jekk tixtri prodotti ta 'kwantità kbira

Ħossok liberu li tikkuntattjani:

Aimee

Manager tal-bejgħ

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Distrett Tianyuan, Belt Zhuzhou.

Email: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688