- Tungsten carbide

- Coating: PVD

- Hardness: 92HRA

Deskrizzjoni

CCMT09T302-FM4 Turning Carbide Inserts in China

1.Product description:

The advantages:

1. Good chip control for steel machining . Provides perfect turning surface of the workpiece .

2. CVD coating ensures the high wear resistance.

3. Less tool breakage, saving costs and reduce the cost of each component to increase the profits .

4. Long tool life, get higher machine utilization and higher production.

5. A reliable and secure performance every time.

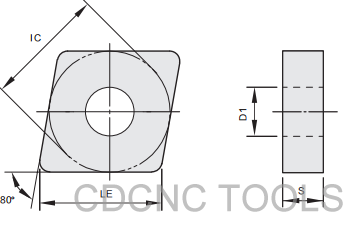

2.design drawings:

Insert Shape |

Type | Dimension | |||||

LE |

IC |

S |

D1 |

RE | |||

| Semi Finishing | CNMG120404-OMM | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

CNMG120408-OMM | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG160608-OMM | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 | ||

| CNMG090308-MF | 9.7 | 9.525 | 3.18 | 3.81 | 0.8 | |

CNMG120408-MF | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG120412-MF | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

CNMG160612-MF | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 | ||

| CNMG120404-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 | |

CNMG120408-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG120412-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

| Roughing | CNMG120408-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

CNMG120412-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

CNMG120416-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 1.6 | ||

CNMG160608-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 | ||

CNMG160612-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 1.2 | ||

CNMG160616-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 | ||

CNMG190608-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 0.8 | ||

CNMG190612-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 1.2 | ||

CNMG190616-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 1.6 | ||

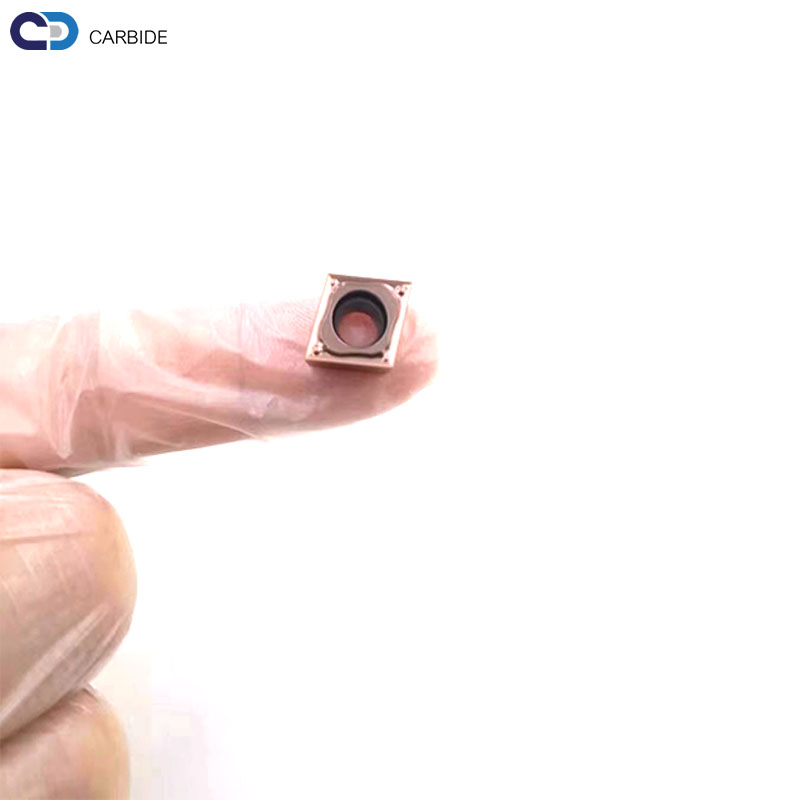

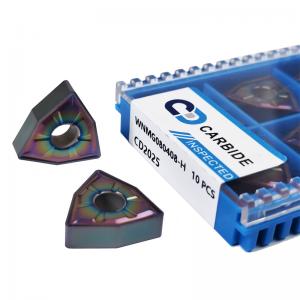

3. product show:

5.Grade:

| Grade for Turning Inserts | ||||

| GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

| CD8025 | CVD | golden yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. MT-TiCN+Al2O3+TiN coating has very good surface quality and help to recognize wear easily. It is suitable for semi-finishing and finishing steel machining. |

| (MT-TiCN+Al2O3+TiN) | ||||

| CD8125 | CVD | black | P10-P40 | The carbide substrate have mild cobalt content and high cubic content, combining with thick TiCN and Al2O3, treated by sepcial technology after coating treatment, which gives inserts strong wearing resistance. It is prority for semi-finishing to finishing steel machining. |

| (Multi-TiCN+Al2O3) | ||||

| CD8020 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel. |

| CD8010 | CVD | black | K10-K30 | The medium-coarse substrate combine with thick TiCN and textured Al2O3, after special coating treatment, it has strong |

| (thick TiCN+ textured Al2O3) | wear-resistance. The grade is suitable for high-speed semi-finishing cast iron turning under stable working condition. | |||

FAQ

1) Meta nista 'nikseb il-prezz?

Normalment nikkwotaw fi żmien 24 siegħa wara li nġibu l-inkjesta tiegħek. Jekk int urġenti ħafna biex tikseb il-prezz, jekk jogħġbok ċempelna jew għidilna fl-email tiegħek sabiex inqisu l-prijorità tal-inkjesta tiegħek.

2) Kif nista 'nikseb kampjun biex niċċekkja l-kwalità tiegħek?

Wara l-konferma tal-prezz, tista 'teħtieġ li l-kampjuni jiċċekkjaw il-kwalità tagħna. Jekk għandek bżonn biss kampjun vojt biex tiċċekkja d-disinn u l-kwalità tal-karta, aħna nipprovdulek kampjun b'xejn, sakemm taffordja l-merkanzija espressa.

3) Kemm nista' nistenna li nikseb il-kampjun?

Wara li tħallas il-ħlas tal-kampjun u tibgħatilna fajls ikkonfermati, il-kampjuni jkunu lesti għall-kunsinna fi żmien 3-7 ijiem. Il-kampjuni jintbagħtulek permezz express u jaslu fi 3-7 ijiem tax-xogħol. Tista' tuża l-kont espress tiegħek stess jew tħallasna minn qabel jekk ma jkollokx kont.

4) Kemm idum il-proċedura kollha li qed tinħadem?

Wara li tagħmel ordni, il-ħin tal-immaniġġjar tal-produzzjoni huwa ta 'madwar 20-25 jum. Għandna bżonn 7 ijiem biex nippreparaw l-għalf kollu imbagħad 15-il jum għall-manifattura.

5) Xi ngħidu dwar it-trasport u d-data tal-kunsinna?

Normalment nużaw il-vjaġġ bil-baħar biex jittrasportaw il-merkanzija. Huwa ta 'madwar 7-25 ġurnata. Jiddependi wkoll minn liema pajjiż u port int. Jista' jkun iqsar jekk għandek bżonn tibgħat l-oġġetti bħall-Asja. Jekk ikun hemm xi emerġenzi nistgħu nibagħtu l-merkanzija permezz ta 'air express, sakemm taffordja l-ispiża tat-traffiku.

6) Int kumpanija kummerċjali jew manifattur?

Aħna manifattur professjonali. Aħna mhux biss tippossjedi l-fabbrika tal-għodod tagħna, iżda għandna wkoll fabbrika tal-karbur tas-siment.

7) Fejn tinsab il-fabbrika tiegħek?

Aħna jinsabu fil-belt ta 'Zhuzhou, Provinċja ta' Hunan., belt bażi tal-karbur tat-tungstenu taċ-Ċina

8) Kemm nista' nistenna li nikseb il-kampjun?

Wara li tħallas il-ħlas tal-kampjun u tibgħatilna fajls ikkonfermati, il-kampjuni jkunu lesti għall-kunsinna fi żmien 3-7 ijiem. Il-kampjuni jintbagħtulek permezz express u jaslu fi 3-5 ijiem tax-xogħol. Tista' tuża l-kont espress tiegħek stess jew tħallasna minn qabel jekk ma jkollokx kont.

9) Kif dwar l-istokk tiegħek?

Għandna prodotti ta 'kwantità kbira fl-istokk, tipi u daqsijiet regolari huma kollha fl-istokk.

10) Huwa possibbli tbaħħir b'xejn?

Aħna ma noffrux servizz ta 'tbaħħir b'xejn. Nistgħu jkollna skont jekk tixtri prodotti ta 'kwantità kbira

Ħossok liberu li tikkuntattjani:

Aimee

Manager tal-bejgħ

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Distrett Tianyuan, Belt Zhuzhou.

Email: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688