How to choose a carbide burr correctly?

Choosing the right carbide burr is essential to ensure efficient processing and work safety. Here are the steps

and considerations for choosing a carbide burr:

1. Determine the processing material and application scenario

Material type:Determine the material you need to process, such as steel, aluminum, copper, wood, etc. Different

carbide burrs are suitable for different types of materials.

Processing requirements:Consider whether it is rough processing, finishing or processing of a specific shape,

such as chamfering, grooving, opening, etc.

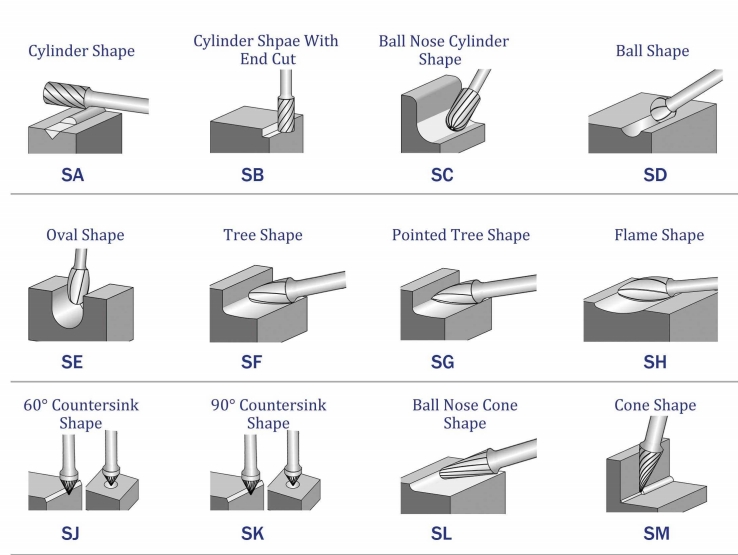

2. Choose the right carbide rotary burr shape and cutting type

Shape:Carbide burrs have a variety of shapes, such as spherical, cylindrical, conical, round head, comb, etc.

Choose a shape that suits your processing needs to ensure that the expected processing effect can be achieved.

Cutting type:Choose single cut, double cut, or diamond cut as needed. Each cutting type has its own unique

application scenario and cutting characteristics.

3. Determine the size and fit of the carbide burr bit

Diameter and length:Choose the carbide burr size that fits your equipment, usually measured in diameter and

length (length of the working part).

Clamping method:Make sure the clamping method of the carbide burr (usually 1/4 inch or 1/8 inch diameter)

is compatible with your processing equipment, such as handheld air tools or electric tools.

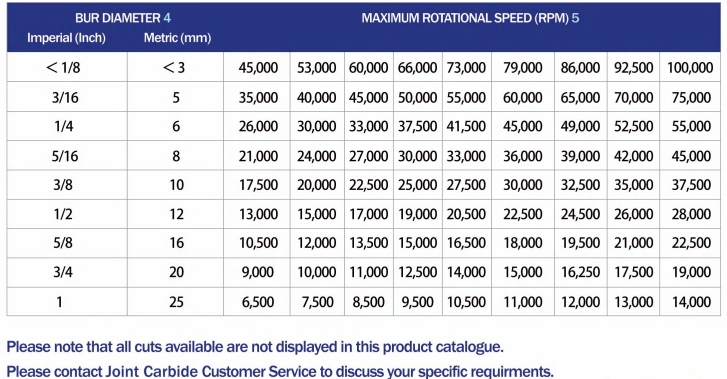

4. Consider processing speed and cutting quality

RPM recommendation:Understand the optimal speed range of the carbide burr to avoid too high or too low

speed affecting cutting effect and tool life.

Cutting quality:Choose a carbide burr with excellent cutting quality that can provide smooth surfaces and

precise processing dimensions.

5. Pay attention to safety and durability

Wear resistance and high temperature resistance:Make sure the selected carbide burr has sufficient wear

resistance and high temperature resistance to cope with long-term and high-intensity processing requirements.

Safety measures:Always wear safety glasses and gloves when using a carbide burr to prevent injuries caused

by flying metal chips and debris.

By following the above steps, you can be more confident in choosing the carbide burr that suits your

processing needs, thereby improving production efficiency and processing quality, while ensuring work safety

and tool life.

welcome to choose carbide burr from our website: https://www.cdcnctools.com/Carbide-burr.html