Kutembenuka Kusankha: Kusankha Kwabwino Kwambiri Padziko Lonse

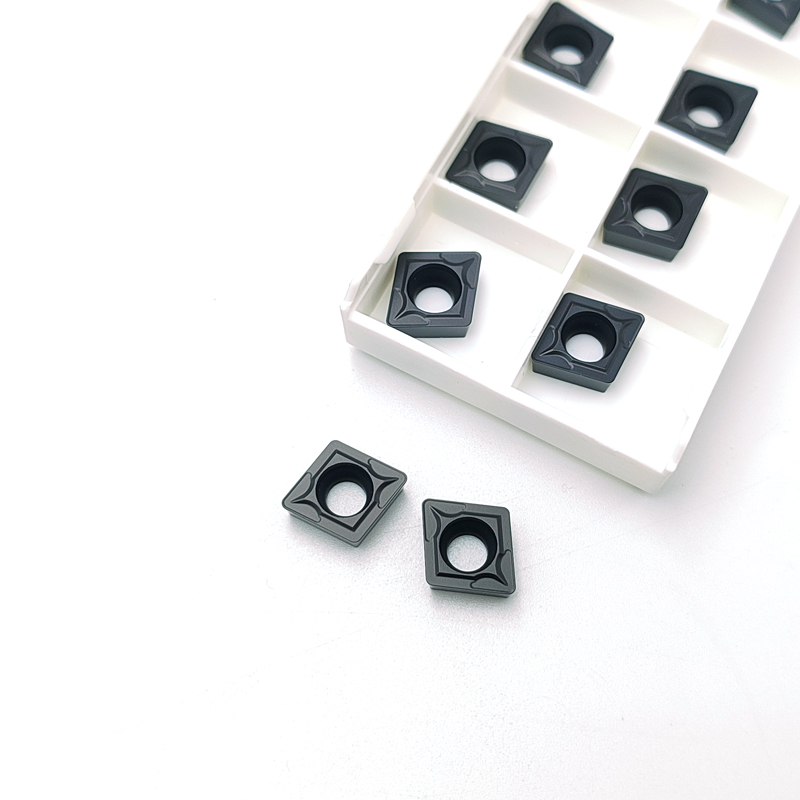

Kutembenuka Kuyikandi zigawo zigawo zomwe zimagwiritsidwa ntchito mu lathe. Ntchito yawo yayikulu ndikuchotsa zowonjezera kuchokera kuntchito kudzera mu gulu lozungulira pakati pa chowongolera chozungulira ndi chokhazikika, potero mumayesa ntchito yomwe mukufuna ndi kukula kwake. Zili ngati chida cholondola chonyamula zinthu zomwe zingathetse zinthu zosiyanasiyana ndikuchita zazikulu mu gawo la kupanga makina.

Poyerekeza ndi zida zachikhalidwe, ma caring a carbide amakhala ndi maubwino otsatirawa

1. Kuuma kwakukulu ndi kuvala kukana:

Kuumitsa kwa carbide ndikokwera kwambiri kuposa momwe zida zimakhalira ndi zida zachikhalidwe, monga chitsulo chothamanga kwambiri. Izi zimathandiza kuti ma carbide osintha kukhala akuthwa bwino panthawi yodulira ndikupewa kuvala zomangira pamphumi, potero kukulitsa moyo wa Mbali. Mwachitsanzo, pokonza zinthu zolimba kwambiri ngati ma elloy chitsulo komanso chitsulo chouma, kuvala kukana kwa ma carbide makamaka.

2. Mphamvu zazikulu komanso kulimba:

Zipangizo zamagalimoto sizokhazokha, komanso khalani ndi mphamvu zina komanso kulimba. Potembenuka, amatha kupirira mphamvu zambiri ndikusintha mphamvu, ndipo sakonda kupsinjika ndi kuwonongeka. Mosiyana ndi izi, zida zachikhalidwe zachikhalidwe zimakonda kusokonezeka ndikuwonongeka mukakhala ndi katundu waukulu, zomwe zikukhudza kulondola komanso kuchita bwino.

3. Kukhazikika Kwabwino:

Kutentha kwakukulu kumapangidwa mukamasinthira, kupangitsa kuti kutentha kwa chikhale bwino. Zovala za Carbide ali ndi kutentha kwambiri komanso kukhazikika kwa matenthedwe, kumatha kukhalabe ndi mphamvu pamakina otentha kwambiri, ndipo sizophweka kufewetsa kapena kusokonekera chifukwa cha kutentha kwambiri. Izi zimapangitsa kuti magalimoto azisintha ma carbide omwe amasinthana bwino mosenda kwambiri, kudula kowuma ndi zinthu zina zogwirira ntchito, ndipo zitha kuwonetsetsa kuti kukonza bwino komanso kulondola.

4.. Kuwongolera bwino komanso kudula kwabwino:

Kutanthauzira kwa kapangidwe ka kanyumba kanyumba kumakhala kokwanira, komanso kulondola kwapamwamba, kungokhala kulondola kwa masamba atha kukhala otsimikizika. Izi zimathandiza kuti masamba azitha kudula molondola panthawi yodulira, ndipo ntchito zopangira zomwe zimachitika zimakhala ndi zolondola komanso zabwino. Nthawi yomweyo, kudula mutu wa ma carbide ndi lakuthwa ndi kovuta komanso kocheperako ndikochepa, komwe kumachepetsa mphamvu, kuchepetsa zida zamakina, ndikusintha zida zamakina.

5.

Kuyika kwa carbides kubisala kumatha kusankha zida zosiyanasiyana, mawonekedwe, kukula ndi zokutira mosiyanasiyana, kuphatikiza chitsulo chosiyanasiyana, ndi matalala ochulukirapo.

Zolemba Zogwiritsira Ntchito

1.Roughing:

Mu mtundu woyipa, kusinthika kumagwiritsidwa ntchito makamaka kuchotsa mwachangu zinthu zambiri. Pakadali pano, amaika ndi zigawo zazikulu zodulira komanso kulimba kwambiri nthawi zambiri kumasankhidwa, monga zigawo zazikuluzikulu za carbide. Makina awa amatha kupirira mphamvu zodulidwa ndikugwiritsa ntchito kuyang'ono kwakukulu ndikumadyetsa kukonza bwino. Mwachitsanzo, mukamagwiritsa ntchito zigawo zazikulu za zigawo zazikulu, kuwononga zigawo zosinthira kumatha kuchotsa zinthu zochuluka ndikupanga ntchito yolumikizirana.

2.Semi-finishing:

Gawo lomalizidwa ndikuwongolera kulondola kwapafupipafupi komanso mawonekedwe ake pamtundu wazomanga. Pakadali pano, zoyika zotembenukira zomwe zasankhidwa ziyenera kukhala ndi kukhazikika kwabwino ndikulondola, zoteremonga ma camond opangidwa ndi ma camond. Mwa kuchepetsa moyenera kudula ndikudya, ntchitoyo imakonzedwa pogwiritsa ntchito mtsinjewo kuti mukonzekere kumaliza.

3.Finishing:

Kumaliza kumafuna kusintha kwa kusinthaku kuti uthe kukonza molondola kwambiri, malo otsika-otsika-otsika. Nthawi zambiri, masamba okhala ndi mbali zakuthwa komanso molondola kwambiri amasankhidwa, monga mapangidwe a croramic kapena ma gwiritsitsani ma carbide ndi zokutira zabwino. Pakadali pano, kudula kwake komanso kuchuluka kwa chakudya ndizochepa kwambiri, ndipo tsamba limagwiritsidwa ntchito kwambiri kudula bwino pa malo ogwirira ntchito. Mwachitsanzo, pokonzanso magawo ambiri monga manja, tsamba lomaliza lotembenukira limatha kupangitsa kuti malo ogwirira ntchito akhale a ra0.8μm kapena zochepa.

Zitsanzo

1.clation ndi zinthu:makamaka carbideng masamba, ma ceramic potembenukira masamba, zitsulo zamitundu, etc. Zida za Carbidet Zida zimakhala ndi kulimbikira kwambiri komanso koyenera, koyenera kukonza zinthu zambiri; Masamba osinthira masamba okhala ndi kuuma kwambiri ndikulimbana, kuyenera kudula kwambiri ndikukonzekera zinthu zolimba; Zida za zitsulo zotembenukira zimaphatikiza zabwino za carbide ndi centics, ndikudulira bwino ndikuthana.

2.clation ndi mawonekedwe:Anthu wamba ndi tyaangle, lalikulu, diamondi, bwalo, etc. Masamba osinthika ndi oyenera kukonzekera mosiyanasiyana, ndikumaliza, ndi masamba a diamondi kuchita bwino

3.Clation pogwiritsa ntchito:Kuphatikiza mabowo akunja, dzenje lamkati la masamba, kudula masamba, kuluma masamba, etc. Tsitsi lililonse la Kutembenuka limapangidwa ndi zosowa zingapo ndikugwiritsa ntchito zofuna kusintha.

Mawonekedwe a zinthu

1.Kulondola komanso kuuma:Kukhala ndi zovuta zapadera monga kuuma kwambiri, kuvala kukana komanso kutsiriza kwa malizani kuti muwonetsetse kusalala.

Tekinoloje ya 2.idadled kuti muwonetsetse kuti: Kukhumudwa ndi kuwuma kumapangidwa kudzera muukadaulo wapamwamba kwambiri ndipo ali ndi mphamvu yolimba komanso nthawi yayitali, ndikudula pang'onopang'ono komanso kuvala zambiri.

3.Kulimbana ndi kupembedzera:Zida zapamwamba kwambiri kuti muchepetse kuvala ndikuchepetsa mikangano, osatha kuyambitsa tsamba kapena kusweka.

Zowonetsera zathu