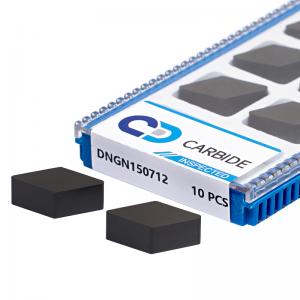

- Material:100% virgin tungsten carbide

- Type: CBN insert

- Coating:As required, PVD CVD, TiAIN, TiCN

- Usage:External turning tool, External turning tools

DESCRIPTION

Product description

Material | tungsten carbide & CBN material |

Coating | As required, PVD CVD, TiAIN, TiCN |

Model Number | WNMG080408/WNMG Series |

Workpiece | Steel/Stainless Steel/Cast Iron |

Place of origin | Zhuzhou,Hunan,China |

Usage | External turning tool, External turning tools |

Introduction to turning inserts

Turning inserts are the most widely used tools in metal cutting. They can be used to process outer circles, end planes, threads, and inner holes on lathes, as well as grooving and cutting. In terms of structure, turning tools can be divided into integral turning tools, welding-assembled turning tools and turning tools with mechanically clamped blades.

Features of tungsten carbide CNC turning inserts

1. High precision: the blade and the tool holder have high precision, and the fine-tuning tool holder is adopted to improve the tool precision.

2. Good reliability: reliable structure, stable chip breaking.

3. Quick tool change: improve processing efficiency.

4. Blade material: carbide, coating material.

5. Tool holder truncation: square, round (related to the lathe tool holder system).

The properties of CNC turning insert materials

1. Hardness and wear resistance. The higher the hardness of the tool material, the better the wear resistance, and the stronger the wear resistance of the cutting part of the tool.

2. Strength and toughness. CNC lathe tools must have sufficient bending strength and impact toughness to avoid fracture and chipping of the tool material during cutting.

3. Heat resistance and chemical stability. The better the heat resistance, the higher the allowable cutting speed and the higher the resistance to plastic deformation of the cutting edge. The better the chemical stability, the slower the tool wear.

4. In addition, CNC turning inserts also have good manufacturability and economy.

FAQ

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2) How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you just need a blank sample to check the design and paper quality, we will provide you sample for free, as long as you afford the express freight.

3) How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-7 workdays. You can use your own express account or prepay us if you do not have an account.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 20-25 days. We need 7 days to prepare all the stuff then 15 days for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 7-25 days.It also denpends on which coutry and port you are.It could be shorter if you need to send the goods like Asian. If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.

6) Are you trading company or manufaturer?

We are professional manufacturer. We not only owns our tools factory, but also have cemented carbide factory.

7) Where is your factory located?

We are located in Zhuzhou city , Hunan Province .,tungsten carbide base town of China

8) How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-5 workdays. You can use your own express account or prepay us if you do not have an account.

9) How about your stock?

We have large quantity products in stock, regular types and sizes are all in stock.

10) Is free shipping possible?

We don't offer free shipping service. We can have a discount if you buy a large quantity products