- Material: tungsten carbide

- Application: cutting steel

- Features: High hardness, wear resistance, heat resistance and corrosion resistance

- Package: 10 pcs per box

DESCRIPTION

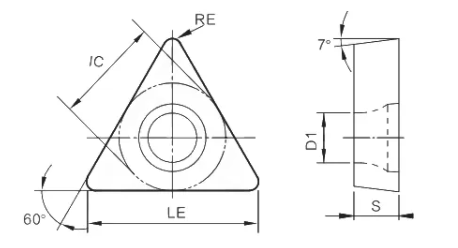

High Stability TCMT110204/TCMT110208 for Steel Machining Carbide Turning Inserts Tools

1.Product Description:

Material | 100% virgin tungsten carbide |

Model | TCMT110204 |

Color | Black/Yellow |

Workpiece | Steel/Stainless steel |

Coating | CVD/PVD coating |

Package | 10pcs/box |

Place of origin | Zhuzhou,Hunan,China |

Feature | Long service life, high wear resistance, high hardness, |

2. Drawings and Type:

3. Grade Chart:

FAQ

1) When can I get the price?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2) How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality. If you just need a blank sample to check the design and paper quality, we will provide you sample for free, as long as you afford the express freight.

3) How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-7 workdays. You can use your own express account or prepay us if you do not have an account.

4) How long does the whole procedure being worked out?

After you place a order,the production handling time is about 20-25 days. We need 7 days to prepare all the stuff then 15 days for manufacturing.

5) What about the transportation and delivery date?

Normally we use shipment to transprot the goods.It is about 7-25 days.It also denpends on which coutry and port you are.It could be shorter if you need to send the goods like Asian. If there are some emergencies we can send the goods via air express, as long as you afford the traffic expense.

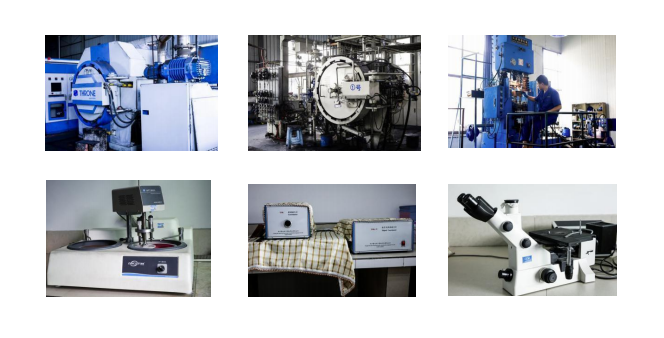

6) Are you trading company or manufaturer?

We are professional manufacturer. We not only owns our tools factory, but also have cemented carbide factory.

7) Where is your factory located?

We are located in Zhuzhou city , Hunan Province .,tungsten carbide base town of China

8) How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-5 workdays. You can use your own express account or prepay us if you do not have an account.

9) How about your stock?

We have large quantity products in stock, regular types and sizes are all in stock.

10) Is free shipping possible?

We don't offer free shipping service. We can have a discount if you buy a large quantity products