- Tungsten carbide

- Coating: AlTiN, TiAIN, TiCN, Tin

- Appllication: Steel Processing

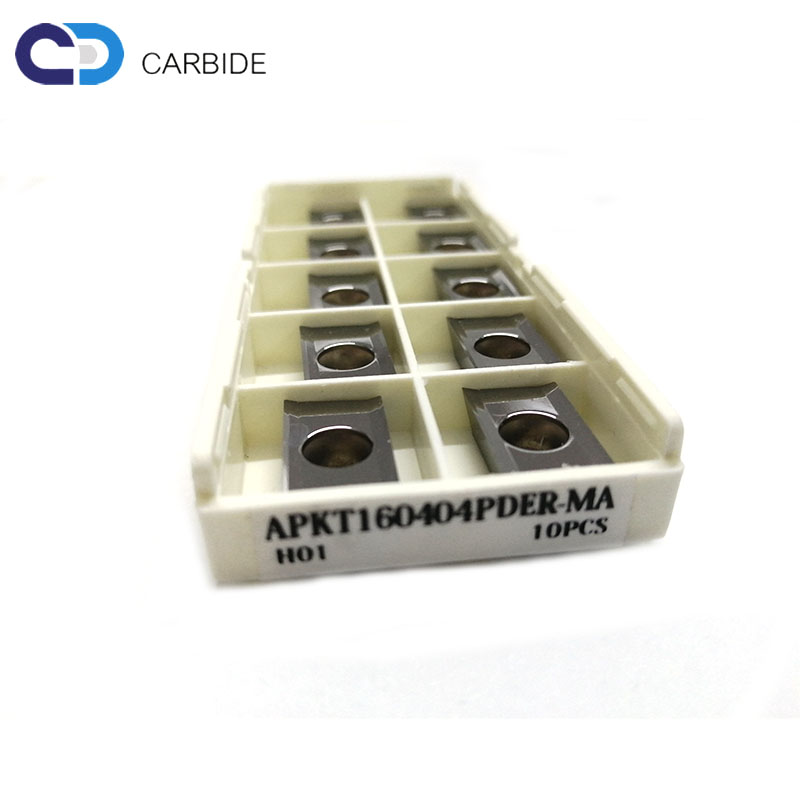

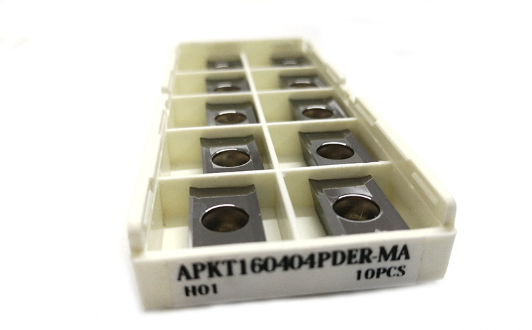

FAAMATALAGA

Tungsten carbide milling tool insert/milling cutters/indexbale milling inserts of APMT1135PDER

1.Prodcut description:

Advantages :

1.Tungsten carbide material

2.Large stock can deliver fast

3.High wear and abrasive resistance

4.Attractive price and high quality with good service

5.Precision ground and polished

3.Product show:

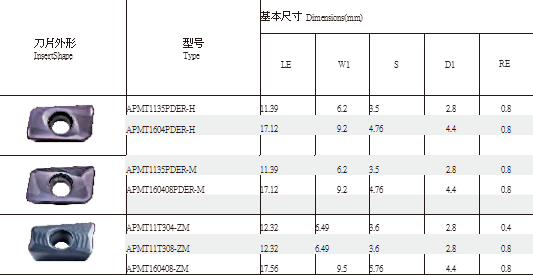

4.Grade:

FAQ

1) O afea e mafai ai ona ou maua le tau?

E masani ona matou sii maia i totonu ole 24 itula talu ona maua lau suʻesuʻega.Afai e te matua faanatinati e maua le tau, faʻamolemole valaʻau mai pe taʻu mai ia i matou i lau imeli ina ia matou manatu i lau suʻesuʻega faʻamuamua.

2) E mafai faapefea ona ou maua se faʻataʻitaʻiga e siaki ai lou tulaga lelei?

A maeʻa faʻamaoniga tau, e mafai ona e manaʻomia mo faʻataʻitaʻiga e siaki ai lo matou lelei. Afai e te manaʻomia se faʻataʻitaʻiga avanoa e siaki ai le mamanu ma le tulaga lelei o pepa, matou te tuʻuina atu ia te oe faʻataʻitaʻiga e aunoa ma se totogi, pe afai e te gafatia le uta faʻaalia.

3) O le a le umi e mafai ona ou faʻamoemoe e maua ai le faʻataʻitaʻiga?

A maeʻa ona e totogiina le tau faʻataʻitaʻiga ma auina mai ia i matou faila faʻamaonia, o le a saunia faʻataʻitaʻiga mo le tuʻuina atu i le 3-7 aso. O faʻataʻitaʻiga o le a tuʻuina atu ia te oe e ala ile faʻaalia ma taunuu ile 3-7 aso faigaluega. E mafai ona e fa'aogaina lau oe fa'amatalaga fa'amatalaga pe totogi muamua matou pe a leai sau teugatupe.

4) O le a le umi e fa'atino ai le fa'agasologa atoa?

A maeʻa ona e tuʻuina se faʻatonuga, o le taimi e faʻatautaia ai le gaosiga e tusa ma le 20-25 aso. Matou te manaʻomia 7 aso e saunia ai mea uma ona 15 aso mo le gaosiga.

5) Ae faapefea le felauaiga ma le tuʻuina atu o aso?

E masani lava matou te faʻaaogaina uta e faʻafeiloaʻi ai oloa. E tusa ma le 7-25 aso. E faʻalagolago foi i le coutry ma le taulaga e te iai. Afai e iai ni fa'alavelave fa'afuase'i e mafai ona matou lafo atu oloa e ala i le ea express, pe afai e te gafatia le tau o felauaiga.

6) O oe kamupani fefaʻatauaʻiga poʻo le faʻatau?

O matou o le gaosiga faʻapolofesa. E le gata ina matou umia a matou fale gaosi mea faigaluega, ae o loʻo iai foʻi fale gaosi carbide sima.

7) O fea o iai lau falegaosimea?

O loʻo matou i totonu o le taulaga o Zhuzhou, Hunan Province., Tungsten carbide base taulaga o Saina

8) O le a le umi e mafai ona ou faʻamoemoe e maua ai le faʻataʻitaʻiga?

A maeʻa ona e totogiina le tau faʻataʻitaʻiga ma auina mai ia i matou faila faʻamaonia, o le a saunia faʻataʻitaʻiga mo le tuʻuina atu i le 3-7 aso. O faʻataʻitaʻiga o le a tuʻuina atu ia te oe e ala ile faʻaalia ma taunuu ile 3-5 aso faigaluega. E mafai ona e fa'aogaina lau oe fa'amatalaga fa'amatalaga pe totogi muamua matou pe a leai sau teugatupe.

9) Faʻafefea lau faʻasoa?

E tele a matou oloa i totonu o faʻatau, ituaiga masani ma lapopoa o loʻo i totonu uma.

10) E mafai ona lafo fua?

Matou te le ofo fua le felauaiga. E mafai ona matou maua se fa'aitiitiga pe afai e te fa'atau se oloa tele

Lagona le saoloto e fa'afeso'ota'i a'u:

Aimee

Pule fa'atau

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Imeli: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688