- Grade: CD7225

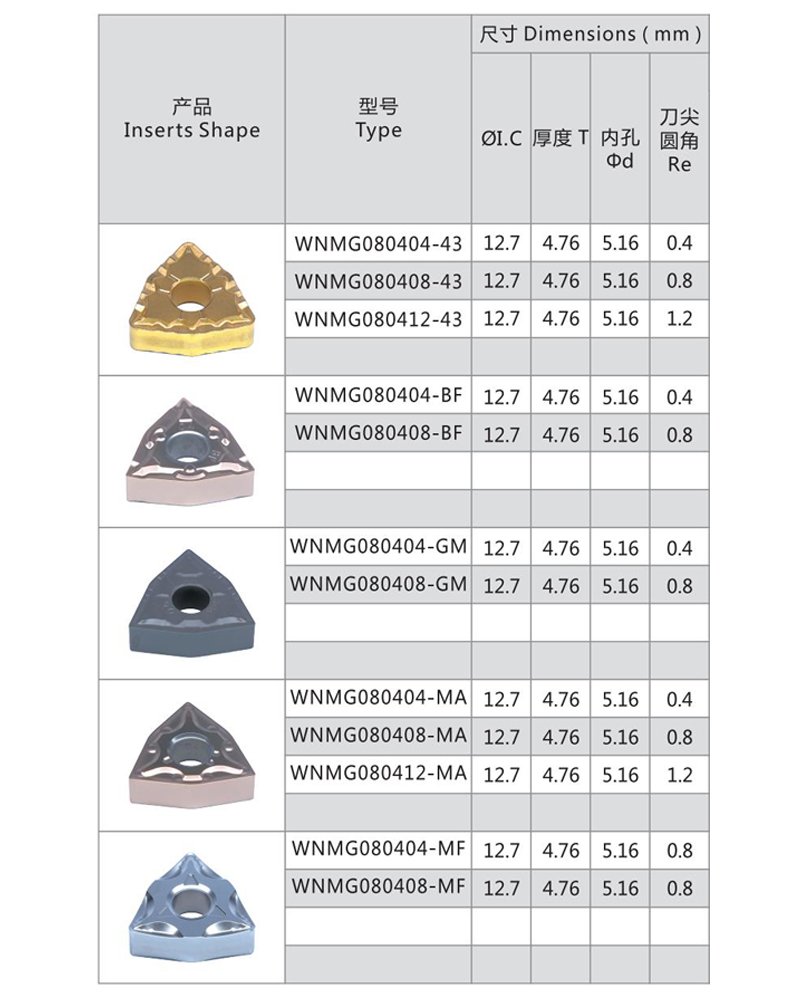

- Model: WNMG080404-MA WNMG080408-MA WNMG080412-MA

- Application: CNC Lathe Machine

- Cutting Condition: High Precision Finishing Cutting

FAAMATALAGA

Cemented tungsten carbide threading turning insert WNMG0804-MA for CNC Lathe Machine

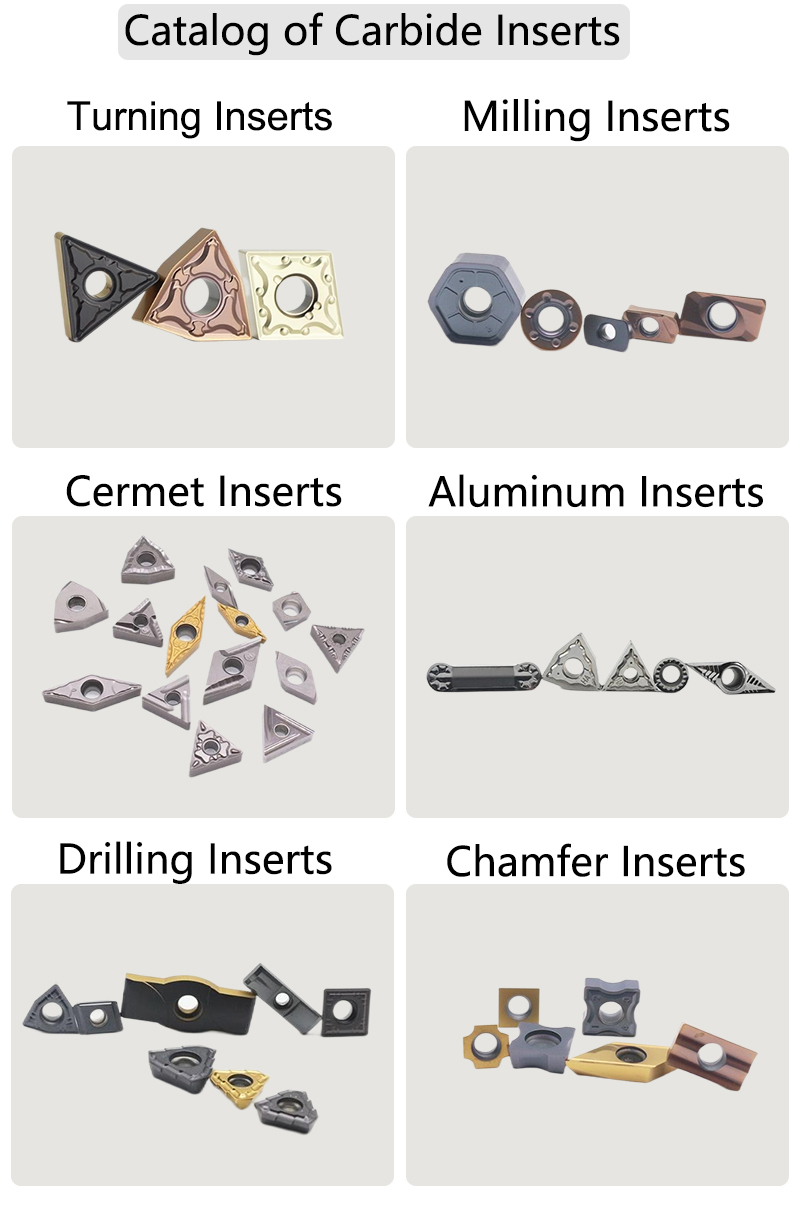

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

FAQ

1) O afea e mafai ai ona ou maua le tau?

E masani ona matou sii maia i totonu ole 24 itula talu ona maua lau suʻesuʻega.Afai e te matua faanatinati e maua le tau, faʻamolemole valaʻau mai pe taʻu mai ia i matou i lau imeli ina ia matou manatu i lau suʻesuʻega faʻamuamua.

2) E mafai faapefea ona ou maua se faʻataʻitaʻiga e siaki ai lou tulaga lelei?

A maeʻa faʻamaoniga tau, e mafai ona e manaʻomia mo faʻataʻitaʻiga e siaki ai lo matou lelei. Afai e te manaʻomia se faʻataʻitaʻiga avanoa e siaki ai le mamanu ma le tulaga lelei o pepa, matou te tuʻuina atu ia te oe faʻataʻitaʻiga e aunoa ma se totogi, pe afai e te gafatia le uta faʻaalia.

3) O le a le umi e mafai ona ou faʻamoemoe e maua ai le faʻataʻitaʻiga?

A maeʻa ona e totogiina le tau faʻataʻitaʻiga ma auina mai ia i matou faila faʻamaonia, o le a saunia faʻataʻitaʻiga mo le tuʻuina atu i le 3-7 aso. O faʻataʻitaʻiga o le a tuʻuina atu ia te oe e ala ile faʻaalia ma taunuu ile 3-7 aso faigaluega. E mafai ona e fa'aogaina lau oe fa'amatalaga fa'amatalaga pe totogi muamua matou pe a leai sau teugatupe.

4) O le a le umi e fa'atino ai le fa'agasologa atoa?

A maeʻa ona e tuʻuina se faʻatonuga, o le taimi e faʻatautaia ai le gaosiga e tusa ma le 20-25 aso. Matou te manaʻomia 7 aso e saunia ai mea uma ona 15 aso mo le gaosiga.

5) Ae faapefea le felauaiga ma le tuʻuina atu o aso?

E masani lava matou te faʻaaogaina uta e faʻafeiloaʻi ai oloa. E tusa ma le 7-25 aso. E faʻalagolago foi i le coutry ma le taulaga e te iai. Afai e iai ni fa'alavelave fa'afuase'i e mafai ona matou lafo atu oloa e ala i le ea express, pe afai e te gafatia le tau o felauaiga.

6) O oe kamupani fefaʻatauaʻiga poʻo le faʻatau?

O matou o le gaosiga faʻapolofesa. E le gata ina matou umia a matou fale gaosi mea faigaluega, ae o loʻo iai foʻi fale gaosi carbide sima.

7) O fea o iai lau falegaosimea?

O loʻo matou i totonu o le taulaga o Zhuzhou, Hunan Province., Tungsten carbide base taulaga o Saina

8) O le a le umi e mafai ona ou faʻamoemoe e maua ai le faʻataʻitaʻiga?

A maeʻa ona e totogiina le tau faʻataʻitaʻiga ma auina mai ia i matou faila faʻamaonia, o le a saunia faʻataʻitaʻiga mo le tuʻuina atu i le 3-7 aso. O faʻataʻitaʻiga o le a tuʻuina atu ia te oe e ala ile faʻaalia ma taunuu ile 3-5 aso faigaluega. E mafai ona e fa'aogaina lau oe fa'amatalaga fa'amatalaga pe totogi muamua matou pe a leai sau teugatupe.

9) Faʻafefea lau faʻasoa?

E tele a matou oloa i totonu o faʻatau, ituaiga masani ma lapopoa o loʻo i totonu uma.

10) E mafai ona lafo fua?

Matou te le ofo fua le felauaiga. E mafai ona matou maua se fa'aitiitiga pe afai e te fa'atau se oloa tele

Lagona le saoloto e fa'afeso'ota'i a'u:

Aimee

Pule fa'atau

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

Imeli: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688