Chii chinonzi carbide inserts chinoshandiswa?

Carbide inoisa inoita basa rakakosha mukushanda kwemazuva ano machining mumaindasitiri akasiyana siyana, nekuda kwavo.

kusimba kwakasiyana-siyana, kuita zvakasiyana-siyana, uye nemazvo. Aya mapeji anoshandiswa muhuwandu hwekucheka uye kuumba

maitiro, achipa mabhenefiti akakosha pamusoro pechinyakare high-speed simbi maturusi. Muchinyorwa chino, tinoongorora

mashandisirwo, zvakanakira, uye zvakakosha kufunga zvine chekuita necarbide inoiswa.

Nhanganyaya kune Carbide Insets:

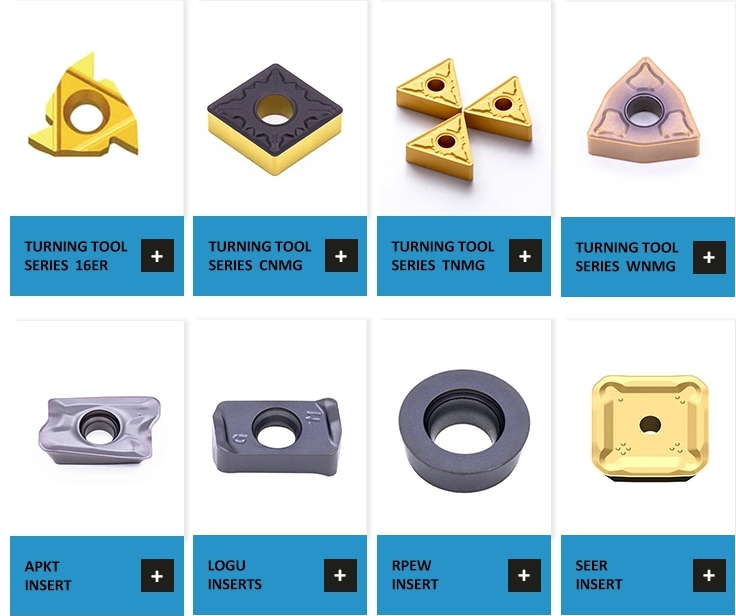

Chuangde mugadziri uye muparidzi wecarbide yekucheka maturusi uye zvine hukama zvigadzirwa zvakavakirwa muZhuzhou, China. Iyo kambani inogadzira maturusi ekucheka e-carbide anoshandiswa mukugadzira uye kugadzira simbi maitiro ekuomarara uye kupfeka kuramba. Izvi zvinosanganisira kuisa, kupera zvigayo, drill, reamers, burr, uye yakakosha tooling. Zvigadzirwa zvayo zvakagadzirirwa Metal working.Tinopa mitengo yakakwirira yemakwikwi uye zvigadzirwa zvemhando. In stock, Yemahara sampuro.

Applications:

Carbide inserts anoshandiswa zvakanyanya mukuchinjisa shinda, kucheka nekukorokoza nezvimwewo. Isarudzo yakanaka pakukorobha, semi-finishing, finishing.general machining of steel, stainless steel necast iron.

1. Kutendeuka uye Kugaya: Carbide anoisa anoshandiswa zvakanyanya mukutenderedza uye kugaya mashandiro munzvimbo dzakafara

zvinhu zvakasiyana-siyana, zvinosanganisira simbi, simbi isina tsvina, simbi yakakandwa, aluminium, uye yakakwirira-tembiricha alloys.

Ivo vanokunda mukugadzira macontours chaiwo, shinda, uye nzvimbo dzine kupedzisa kwepamusoro.

2. Kuboora uye Kufinha: Carbide inoiswa inoshandiswa mukuchera uye inofinha maapplication kugadzira maburi e

kudzika nekudzika kwakasiyana-siyana. Yavo yakakwirira yekupisa conductivity uye kuramba kune deformation inovimbisa

kushanda kunoenderana kunyangwe mumamiriro ezvinhu akaoma ekuchera.

3. Threading: Carbide inoisirwa inosarurwa yekugadzira tambo nekuda kwekugona kwavo kuchengetedza yakapinza

kucheka mipendero pamusoro pekushandisa kwenguva refu, zvichikonzera iwo echokwadi tambo profiles uye kuderedzwa kwezvishandiso kupfeka.

4. Grooving uye Kuparadzana: Carbide inoisa inofambisa inoshanda grooving uye yekuparadzanisa mashandiro, ichigonesa iyo

kusikwa kwematanho akamanikana uye kupatsanurwa kwemaworkpieces ane kushomeka kwekutambisa zvinhu.

5. High-Speed Machining (HSM):Kuisa Carbide kunokosha mukushandisa kweHSM uko zvinhu zvinokurumidza

kubviswa mitengo kwakakosha. Kuoma kwavo kwepamusoro uye kugadzikana kwekupisa kunogonesa kukurumidza kucheka

uye mitengo yekudyisa, inosimudzira kugadzirwa uye kudhura-kushanda.

Zvakanakira:

1. Yakawedzerwa Chishandiso Hupenyu: Carbide inoisa inoratidza yakarebesa hupenyu hwematurusi zvichienzaniswa neyakajairwa yakakwirira-kumhanya.

maturusi esimbi, kuderedza maturusi ekuchinja uye nguva yekudzikira.

2. Kuwedzeredzwa Kugadzirwa: Iyo yepamusoro yekucheka kuita uye kupfeka kuramba kweiyo carbide inoisa inoguma

kukurumidza machining kumhanya uye kuwedzera throughput, kuwedzera kubereka kwese.

3. Yakanatsiridzwa Yepamusoro Pedzisa: Carbide inoisa inoburitsa yakatsetseka pamusoro pekupedzisira ine maburrs mashoma uye hurema,

kubvisa kudiwa kwechipiri kupedzisa mashandiro uye kuvandudza chikamu chemhando.

4. Kushanda kwakasiyana-siyana: Carbide inoiswa inowanikwa mune dzakasiyana siyana dzejometri, machira, uye mamakisi akagadzirirwa

chaiyo machining application, ichipa kuita kwakasiyana-siyana uye kuchinjika mukusarudza chishandiso.

5. Kuchengeta Mutengo: Pasinei nemutengo wavo wepamusoro wekutanga, carbide inoisa inopa mutengo wepamusoro pane yavo.

Hupenyu hurefu nekuda kwekuderedzwa kwemari yekushandisa, yakawedzera kugadzirwa, uye yakaderera pachikamu-chikamu mutengo wekugadzira.

Mukupedzisa, kuiswa kwecarbide kunomiririra ibwe repakona remazuva ano machining tekinoroji, ichipa isingaenzaniswi kuita, kuita kwakasiyana-siyana, uye kugona kwemutengo pane dzakasiyana siyana dzekushandisa.