Lisebelisoa tsa carbide li sebelisetsoa eng?

Lisebelisoa tsa Carbide li bapala karolo ea bohlokoa ts'ebetsong ea mochini oa sejoale-joale ho pholletsa le liindasteri tse fapaneng, ka lebaka la bona.

ho tšoarella ho ikhethang, ho feto-fetoha ha maemo, le ho nepahala. Lisebelisoa tsena li sebelisoa ka mefuta e mengata ea ho itšeha le ho etsa sebōpeho

lits'ebetso, tse fanang ka melemo e mengata ho feta lisebelisoa tsa tšepe tse lebelo le holimo. Sehloohong sena, re hlahloba

lisebelisoa, melemo, le lintlha tsa bohlokoa tse amanang le ho kenya carbide.

Kenyelletso ea Carbide Insets:

Chuangde ke moetsi le morekisi oa lisebelisoa tsa ho seha carbide le lihlahisoa tse amanang le tsona tse thehiloeng Zhuzhou, China. Khamphani e hlahisa lisebelisoa tsa ho itšeha tsa carbide tse sebelisoang mekhoeng ea machining le ea tšepe bakeng sa ho thatafala le ho hanyetsa ho roala. Tsena li kenyelletsa li-insert, li-end Mills, li-drill, reamers, burr, le lisebelisoa tse khethehileng. Lihlahisoa tsa eona li etselitsoe ho sebetsa ka Metal.Re fana ka litheko tse phahameng tsa tlhōlisano le lihlahisoa tsa boleng. E fumaneha, sampole ea mahala.

Lisebelisoa:

Lisebelisoa tsa carbide tse sebelisoang haholo ho fetola khoele, ho seha le ho betla.

1. Ho phethoha le ho Milling: Lisebelisoa tsa carbide li sebelisoa haholo ts'ebetsong ea ho reteleha le ho sila hohle

mefuta e mengata ea lisebelisoa, ho kenyelletsa tšepe, tšepe e sa hloekang, tšepe e entsoeng ka tšepe, aluminium le li-alloys tse phahameng tsa mocheso.

Li ipabola ka ho etsa li-contours, likhoele le bokaholimo bo nang le bokaholimo bo holimo.

2. Ho cheka le ho bora: Li-insert tsa Carbide li sebelisoa ho cheka le lits'ebetso tse borang ho theha masoba a

botebo le bophara bo fapaneng. Ts'ebetso ea bona e phahameng ea mocheso le ho hanyetsa deformation ho netefatsa

tshebetso e tsitsitseng esita le maemong a thata a ho cheka.

3. Khoele: Lisebelisoa tsa carbide li khethoa bakeng sa ts'ebetso ea likhoele ka lebaka la bokhoni ba tsona ba ho boloka li le bohale

ho itšehla thajana ka lebaka la tšebeliso ea nako e telele, e hlahisang lintlha tse nepahetseng tsa likhoele le ho fokotseha ha lisebelisoa tsa lisebelisoa.

4. Grooving le Karohano: Lisebelisoa tsa Carbide li thusa ho sebetsa ka mokhoa o atlehileng oa grooving le karohano, ho nolofalletsa

ho theha likanale tse moqotetsane le karohano ea li-workpieces tse nang le tšenyo e nyane ea thepa.

5. High-Speed Machining (HSM): Lisebelisoa tsa carbide li bohlokoa haholo lits'ebetsong tsa HSM moo thepa e potlakileng.

litefiso tsa ho tlosa li bohlokoa. Ho thatafala ha tsona le ho tsitsisa ha mocheso ho etsa hore ho be le lebelo le tsitsitseng la ho itšeha

le litekanyetso tsa lijo, ho matlafatsa tlhahiso le ho boloka litšenyehelo.

Melemo:

1. Bophelo ba Sesebelisoa bo Atolositsoeng: Lisebelisoa tsa Carbide li bonts'a bophelo bo bolelele ba sesebelisoa ha bo bapisoa le lebelo le tloaelehileng le phahameng.

lisebelisoa tsa tšepe, ho fokotsa ho fetoha ha lisebelisoa le ho fokotsa nako.

2. Tlhahiso e Ntlafetseng: Ts'ebetso e phahameng ea ho itšeha le ho apara ho hanyetsa ha li-carbide ho kenya ho fella ka

lebelo la machining le ntseng le eketseha, ho matlafatsa tlhahiso ka kakaretso.

3. Qetello e Ntlafetseng ea Bokahohle: Lisebelisoa tsa Carbide li hlahisa lithaelese tse boreleli tse nang le li-burrs tse nyane le liphoso,

ho felisa tlhokahalo ea ts'ebetso ea ho qetela ea bobeli le ho ntlafatsa boleng ba karolo.

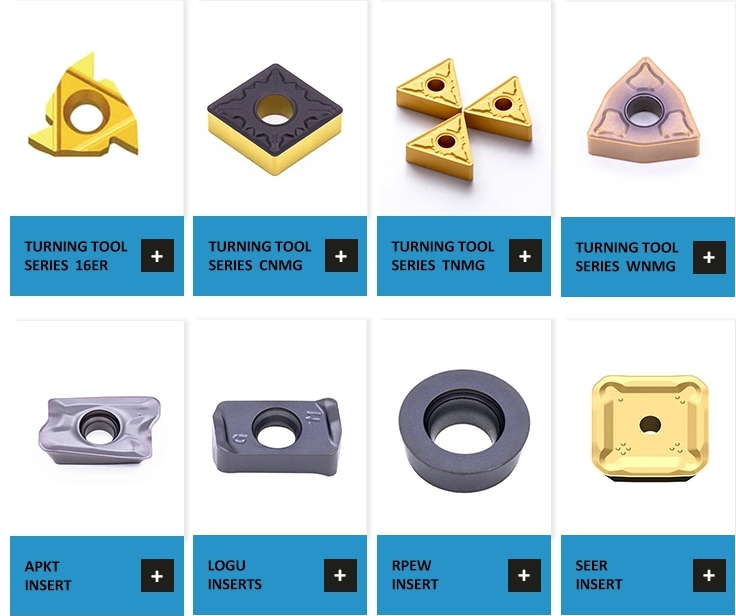

4. Mefuta-futa: Li-carbide tse kentsoeng li fumaneha ka mefuta e mengata ea lijeometri, lirafshoa le limaraka tse etselitsoeng

lisebelisoa tse khethehileng tsa machining, tse fanang ka mekhoa e mengata le ho feto-fetoha ha khetho ea lisebelisoa.

5. Ho Boloka Litšenyehelo: Ho sa tsotellehe litšenyehelo tsa bona tse phahameng tsa pele, lisebelisoa tsa carbide li fana ka litšenyehelo tse phahameng ho feta tsa bona.

nako ea bophelo ka lebaka la litšenyehelo tse fokotsehileng tsa lisebelisoa, tlhahiso e ntlafalitsoeng, le litšenyehelo tse tlase tsa karolo e 'ngoe le e 'ngoe ea mochini.

Qetellong, lisebelisoa tsa carbide li emela lejoe la sekhutlo la theknoloji ea morao-rao ea machining, e fanang ka ts'ebetso e ke keng ea lekanngoa, ho feto-fetoha ha maemo, le katleho ea litšenyehelo ho pholletsa le mefuta e fapaneng ea likopo.