- lintho tse bonahalang: tungsten carbide

- Kopo: ts'ebetso ea tšepe e sa hloekang

- Mekhoa ea ho sebetsa: Ho qetela

Tlhaloso

Tlhaloso ea Sehlahisoa:

1. Lintlha tsa Motheo:

Lisebelisoa tsa ho seha Tungsten carbide kenya WNMG080404-OPM CNC Insets

Mohlala | WNMG060404/08 | WNMG080404/08/12 | WNMA080404/08/12 |

Kereiti | CD8025/CD8125/CD8020/CD8010 | ||

Mosebetsi | tshepe/ tshepe e thatafetseng/ tshepe e sa hlwekang/ tshepe e lahliloeng | ||

Ho roala | Ho roala ha CVD/PVD | ||

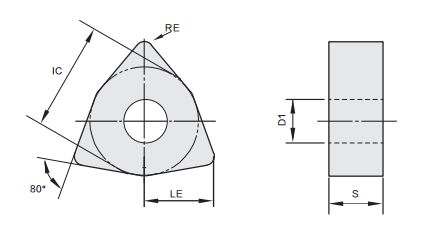

2. Moralo oa Moralo:

Kenya Sebopeho |

Mofuta | Boemo | |||||

LE |

IC |

S |

D1 |

RE | |||

|

Semi Finishing | WNMG060408-OPM | 6.5 | 9.525 | 4.76 | 3.81 | 0.8 |

WNMG080404-OPM | 8.7 | 12.7 | 4.76 | 5.16 | 0.4 | ||

WNMG080408-OPM | 8.7 | 12.7 | 4.76 | 5.16 | 0.8 | ||

WNMG080412-OPM | 8.7 | 12.7 | 4.76 | 5.16 | 1.2 | ||

WNMG060408-OMM | 6.5 | 9.525 | 4.76 | 3.81 | 0.8 | ||

WNMG060412-OMM | 6.5 | 9.525 | 4.76 | 3.81 | 1.2 | ||

WNMG080404-OMM | 8.7 | 12.7 | 4.76 | 5.16 | 0.4 | ||

WNMG080408-OMM | 8.7 | 12.7 | 4.76 | 5.16 | 0.8 | ||

WNMG080412-OMM | 8.7 | 12.7 | 4.76 | 5.16 | 1.2 | ||

| WNMG060408-MF | 6.5 | 9.525 | 4.76 | 3.81 | 0.8 | |

WNMG080408-MF | 8.7 | 12.7 | 4.76 | 5.16 | 0.8 | ||

WNMG080412-MF | 8.7 | 12.7 | 4.76 | 5.16 | 1.2 | ||

3. Lenaneo la Sehlahisoa:

4.

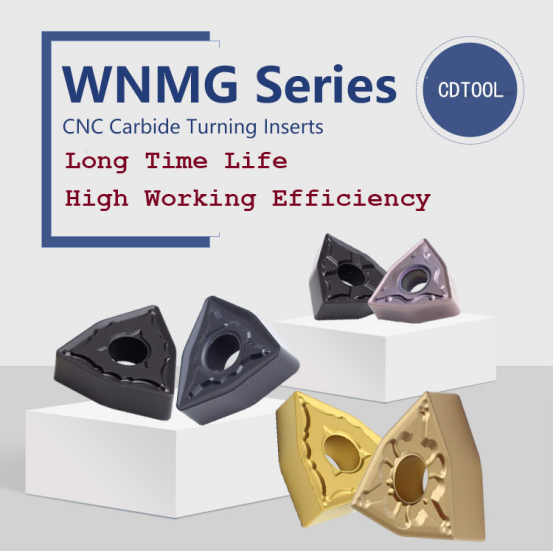

Kereiti ea Cemented Carbide e kenya mofuta oa WNMG Insert CNC Indexable Cutter PVD Coating

| Kereiti ya ho Fetola Insets | ||||

| MPHATO | PHEKO | MOLAOLI | LIEKETSENG MOSEBETSI | KOPO |

| CD8025 | CVD | bosehla ba kgauta | P10-P30 | Carbide substrate e na le khanyetso e ntle ea anti-deformation le ho tiea. MT-TiCN+Al2O3+TiN coating e na le boleng bo holimo haholo 'me e thusa ho lemoha ho apara habonolo. E loketse ho qeta halofo le ho qeta machining a tšepe. |

| (MT-TiCN+Al2O3+TiN) | ||||

| CD8125 | CVD | ntsho | P10-P40 | Carbide substrate e na le lintho tse bonolo tsa cobalt le li-cubic tse ngata, tse kopantsoeng le TiCN e teteaneng le Al2O3, e tšoaroang ke theknoloji ea sepcial ka mor'a phekolo ea ho roala, e fanang ka ho kenya ho hanyetsa ho matla ho apara. Ke prority bakeng sa semi-finishing ho qetela machining tšepe. |

| (Multi-TiCN+Al2O3) | ||||

| CD8020 | PVD (Silicon+TiAlN) | pherese | M10-M30 | Micro WC grain substrate e nang le high Co e boloka matla a ho itšeha 'me e na le khohlano e nyane le ho thatafala ha nano e nang le silicon e tsitsitseng e tsitsitseng ea mocheso. Kereiti e ntle haholo bakeng sa ho sitisa ho phethoha le ho sila bakeng sa tšepe e sa hloekang. |

| CD8010 | CVD | ntsho | K10-K30 | Substrate e mahareng e mahoashe e kopane le TiCN e teteaneng le Al2O3 e entsoeng ka masela, kamora kalafo e khethehileng ea ho roala, e na le matla. |

| (TiCN+ e teteaneng e entsoeng ka Al2O3) | ho hanana le ho roala. Mophato o loketse bakeng sa ho phethoha ka tšepe ea tšepe ea semi-finishing ka lebelo le phahameng tlas'a boemo bo tsitsitseng ba ho sebetsa. | |||

LBH

1) Nka fumana theko neng?

Hangata re qotsa ka hare ho lihora tse 24 ka mor'a hore re fumane potso ea hau.

2) Nka fumana mohlala joang ho hlahloba boleng ba hau?

Kamora netefatso ea theko, o ka hloka hore lisampole li hlahlobe boleng ba rona. Haeba u hloka feela sampole e se nang letho ho lekola moralo le boleng ba pampiri, re tla u fa sampole mahala, ha feela u khona ho reka thepa e potlakileng.

3) Nka lebella ho fumana sampole nako e kae?

Ka mor'a hore u lefelle tefo ea mohlala 'me u re romelle lifaele tse tiisitsoeng, mehlala e tla be e loketse ho tsamaisoa ka matsatsi a 3-7. Mehlala e tla romelloa ho uena ka tsela ea Express 'me e fihle ka mor'a matsatsi a 3-7 a mosebetsi. U ka sebelisa ak'haonte ea hau ea Express kapa ua re lefa esale pele haeba u sena ak'haonte.

4) Tsamaiso eohle e sebetsa nako e kae?

Ka mor'a hore u behe taelo, nako ea ho sebetsana le tlhahiso e ka ba matsatsi a 20-25. Re hloka matsatsi a 7 ho lokisa lintho tsohle ebe matsatsi a 15 bakeng sa tlhahiso.

5) Ho thoe'ng ka letsatsi la lipalangoang le la thomello?

Ka tloaelo re sebelisa thomello ho transprot thepa.E ka ba matsatsi a 7-25. E boetse e itšetlehile ka hore na u coutry le port eo u leng teng.E ka ba khutšoanyane haeba u hloka ho romela thepa e kang ea Asia. Haeba ho na le maemo a tšohanyetso re ka romella thepa ka air Express, ha feela o khona ho lefella litšenyehelo tsa sephethephethe.

6) Na u khoebo ea k'hamphani kapa moetsi?

Re moetsi oa litsebi. Ha re na feme ea lisebelisoa tsa rona feela, empa hape re na le feme ea carbide e samenteng.

7) Feme ea hau e hokae?

Re fumaneha toropong ea Zhuzhou, Profinseng ea Hunan., Tungsten carbide base town of China.

8) Nka lebella ho fumana sampole nako e kae?

Ka mor'a hore u lefelle tefo ea mohlala 'me u re romelle lifaele tse tiisitsoeng, mehlala e tla be e loketse ho tsamaisoa ka matsatsi a 3-7. Mehlala e tla romelloa ho uena ka tsela ea Express 'me e fihle ka mor'a matsatsi a 3-5 a mosebetsi. U ka sebelisa ak'haonte ea hau ea Express kapa ua re lefa esale pele haeba u sena ak'haonte.

9) Ho thoe'ng ka stock ea hau?

Re na le lihlahisoa tse ngata setokong, mefuta e tloaelehileng le boholo bo teng kaofela.

10) Na ho romelloa mahala hoa khoneha?

Ha re fane ka litšebeletso tsa mahala tsa thomello. Re ka ba le theolelo haeba u reka lihlahisoa tse ngata haholo

Ikutloe u lokolohile ho ikopanya le 'na:

Aimee

Mookameli oa thekiso

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Setereke sa Tianyuan, Zhuzhou City.

Lengolo-tsoibila: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688