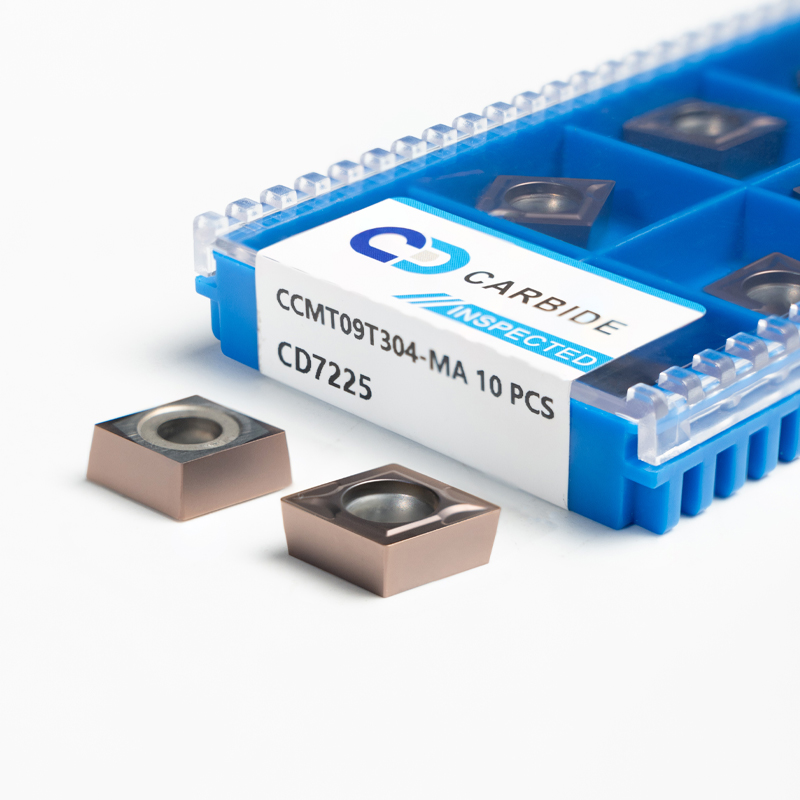

- Grade: CD7225

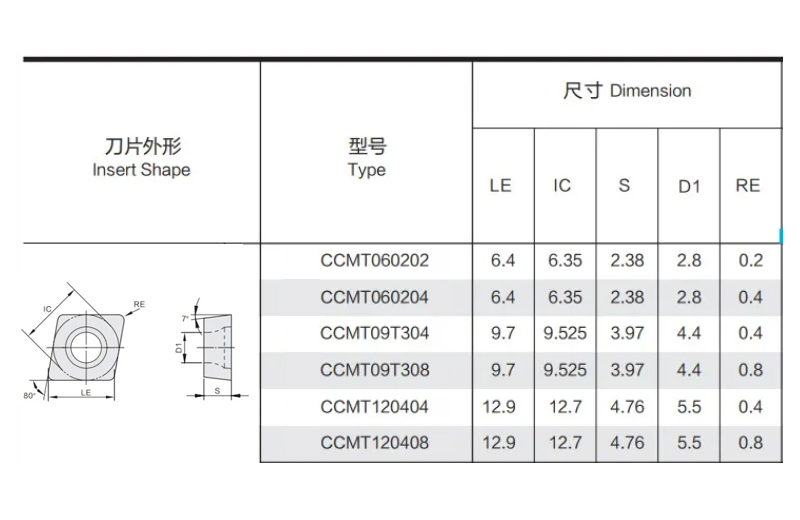

- Model: CCMT09T304-MA DCMT11T308-MA

- Coating:PVD

- Application: Used for steel hard material, stainless steel processing

TLHALOSO

Cemented tungsten carbide turning insert CCMT09T304-MA DCMT11T308-MA for CNC Lathe Machine

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

LBH

1) Nka fumana theko neng?

Hangata re qotsa ka hare ho lihora tse 24 ka mor'a hore re fumane potso ea hau.

2) Nka fumana mohlala joang ho hlahloba boleng ba hau?

Kamora netefatso ea theko, o ka hloka hore lisampole li hlahlobe boleng ba rona. Haeba u hloka feela sampole e se nang letho ho lekola moralo le boleng ba pampiri, re tla u fa sampole mahala, ha feela u khona ho reka thepa e potlakileng.

3) Nka lebella ho fumana sampole nako e kae?

Ka mor'a hore u lefelle tefo ea mohlala 'me u re romelle lifaele tse tiisitsoeng, mehlala e tla be e loketse ho tsamaisoa ka matsatsi a 3-7. Mehlala e tla romelloa ho uena ka tsela ea Express 'me e fihle ka mor'a matsatsi a 3-7 a mosebetsi. U ka sebelisa ak'haonte ea hau ea Express kapa ua re lefa esale pele haeba u sena ak'haonte.

4) Tsamaiso eohle e sebetsa nako e kae?

Ka mor'a hore u behe taelo, nako ea ho sebetsana le tlhahiso e ka ba matsatsi a 20-25. Re hloka matsatsi a 7 ho lokisa lintho tsohle ebe matsatsi a 15 bakeng sa tlhahiso.

5) Ho thoe'ng ka letsatsi la lipalangoang le la thomello?

Ka tloaelo re sebelisa thomello ho transprot thepa.E ka ba matsatsi a 7-25. E boetse e itšetlehile ka hore na u coutry le port eo u leng teng.E ka ba khutšoanyane haeba u hloka ho romela thepa e kang ea Asia. Haeba ho na le maemo a tšohanyetso re ka romella thepa ka air Express, ha feela o khona ho lefella litšenyehelo tsa sephethephethe.

6) Na u khoebo ea k'hamphani kapa moetsi?

Re moetsi oa litsebi. Ha re na feme ea lisebelisoa tsa rona feela, empa hape re na le feme ea carbide e samenteng.

7) Feme ea hau e hokae?

Re fumaneha toropong ea Zhuzhou, Profinseng ea Hunan., Tungsten carbide base town of China.

8) Nka lebella ho fumana sampole nako e kae?

Ka mor'a hore u lefelle tefo ea mohlala 'me u re romelle lifaele tse tiisitsoeng, mehlala e tla be e loketse ho tsamaisoa ka matsatsi a 3-7. Mehlala e tla romelloa ho uena ka tsela ea Express 'me e fihle ka mor'a matsatsi a 3-5 a mosebetsi. U ka sebelisa ak'haonte ea hau ea Express kapa ua re lefa esale pele haeba u sena ak'haonte.

9) Ho thoe'ng ka stock ea hau?

Re na le lihlahisoa tse ngata setokong, mefuta e tloaelehileng le boholo bo teng kaofela.

10) Na ho romelloa mahala hoa khoneha?

Ha re fane ka litšebeletso tsa mahala tsa thomello. Re ka ba le theolelo haeba u reka lihlahisoa tse ngata haholo

Ikutloe u lokolohile ho ikopanya le 'na:

Aimee

Mookameli oa thekiso

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Setereke sa Tianyuan, Zhuzhou City.

Lengolo-tsoibila: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688