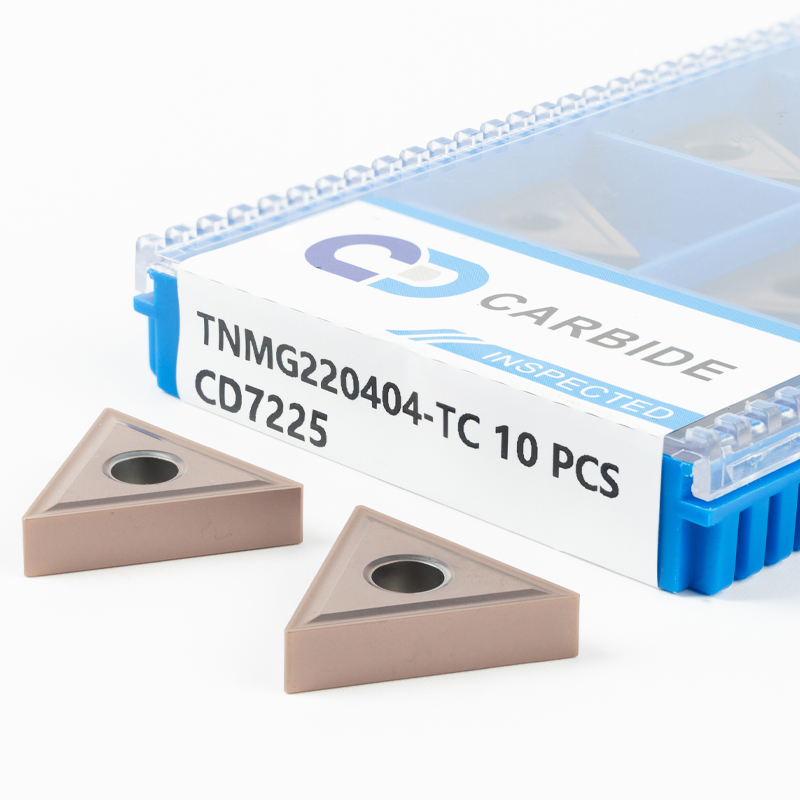

- Grade: CD7225

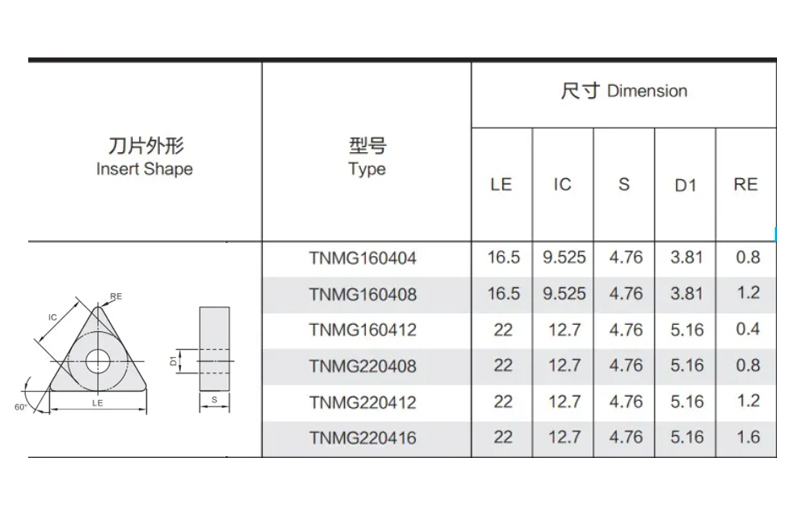

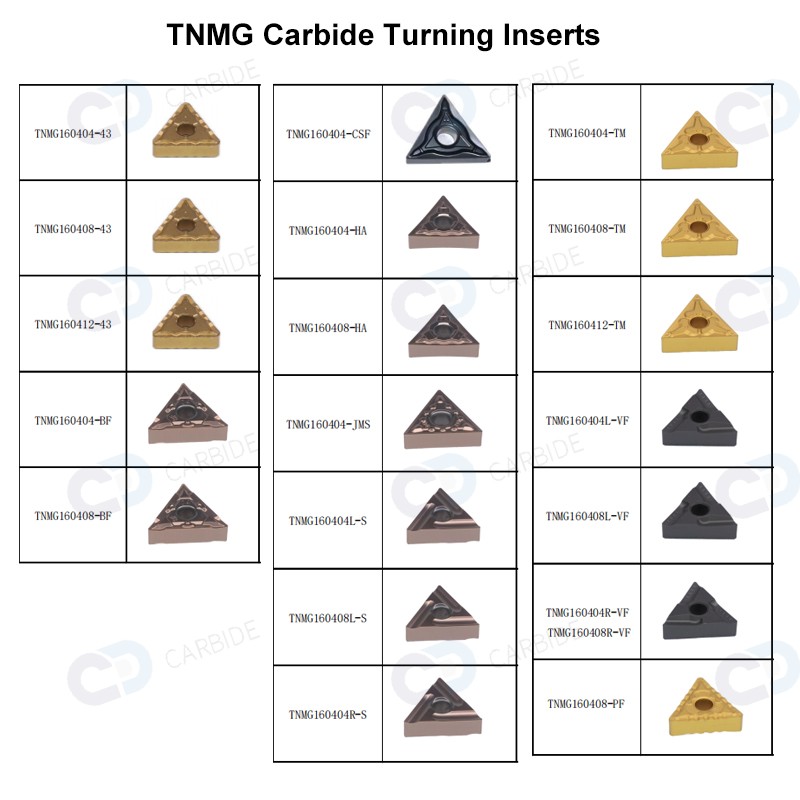

- Model: TNMG220404-TC TNMG220408-TC

- Coating:PVD

- Application: Used for steel hard material, stainless steel processing

Panjelasan

TNMG220404-TC TNMG220408-TC TNMG Carbide cutting tool inserts CNC Lathe Turning Inserts for Steel General machining

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

FAQ

1) Iraha abdi tiasa kéngingkeun hargana?

Urang biasana cutatan dina 24 jam sanggeus urang meunang inquiry.If Anjeun pisan urgent pikeun meunangkeun harga, mangga nelepon kami atawa ngabejaan urang dina email anjeun ku kituna urang bakal nganggap prioritas panalungtikan Anjeun.

2) Kumaha carana abdi tiasa sampel mariksa kualitas anjeun?

Saatos konfirmasi harga, anjeun tiasa meryogikeun conto pikeun pariksa kualitas kami. Upami anjeun ngan ukur peryogi sampel kosong pikeun mariksa desain sareng kualitas kertas, kami bakal nyayogikeun anjeun conto gratis, salami anjeun mampuh angkutan barang ekspres.

3) Sabaraha lami abdi tiasa nyangka meunang sampel?

Saatos Anjeun mayar muatan sampel sarta ngirim kami dikonfirmasi file, sampel bakal siap pikeun pangiriman dina 3-7 poé. Sampel bakal dikirim ka anjeun via express sarta anjog di 3-7 workdays. Anjeun tiasa make akun express sorangan atawa prepay kami lamun teu boga akun.

4) Sabaraha lami sadayana prosedur didamel?

Saatos anjeun nempatkeun pesenan, waktos penanganan produksi sakitar 20-25 dinten. Urang peryogi 7 dinten kanggo nyiapkeun sadaya barang teras 15 dinten kanggo manufaktur.

5) Kumaha upami tanggal transportasi sareng pangiriman?

Biasana kami nganggo kiriman pikeun transprot barang. Éta sakitar 7-25 dinten. Éta ogé gumantung kana coutry sareng palabuhan anjeun. Éta tiasa langkung pondok upami anjeun kedah ngirim barang sapertos Asia. Lamun aya sababaraha kaayaan darurat urang bisa ngirim barang via express hawa, salami anjeun mampuh ongkos lalulintas.

6) Dupi anjeun dagang parusahaan atawa manufaturer?

Kami produsén profésional. Kami henteu ngan ukur gaduh pabrik alat kami, tapi ogé gaduh pabrik karbida anu disemén.

7) Dimana lokasina pabrik anjeun?

Kami lokasina di kota Zhuzhou, Propinsi Hunan., kota dasar tungsten carbide Cina

8) Sabaraha lami abdi tiasa nyangka meunang sampel?

Saatos Anjeun mayar muatan sampel sarta ngirim kami dikonfirmasi file, sampel bakal siap pikeun pangiriman dina 3-7 poé. Sampel bakal dikirim ka anjeun via express sarta anjog di 3-5 workdays. Anjeun tiasa make akun express sorangan atawa prepay kami lamun teu boga akun.

9) Kumaha ngeunaan saham anjeun?

Kami ngagaduhan produk kuantitas ageung, jinis sareng ukuran biasa sadayana aya di saham.

10) Naha pengiriman barang gratis tiasa?

Kami henteu nawiskeun jasa pengiriman barang gratis. Urang bisa boga diskon lamun meuli produk kuantitas badag

Ngarasa Luncat ngahubungan kuring:

Aimee

Ménéjer panjualan

Zhuzhou Chuangde Cemented Carbide Co Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Distrik, Zhuzhou Kota.

Surélék: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688