- Tungsten carbide

- Coating: PVD

- Hardness: 92HRA

MAELEZO

CCMT09T302-FM4 Turning Carbide Inserts in China

1.Product description:

The advantages:

1. Good chip control for steel machining . Provides perfect turning surface of the workpiece .

2. CVD coating ensures the high wear resistance.

3. Less tool breakage, saving costs and reduce the cost of each component to increase the profits .

4. Long tool life, get higher machine utilization and higher production.

5. A reliable and secure performance every time.

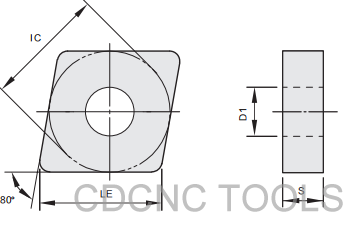

2.design drawings:

Insert Shape |

Type | Dimension | |||||

LE |

IC |

S |

D1 |

RE | |||

| Semi Finishing | CNMG120404-OMM | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

CNMG120408-OMM | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG160608-OMM | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 | ||

| CNMG090308-MF | 9.7 | 9.525 | 3.18 | 3.81 | 0.8 | |

CNMG120408-MF | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG120412-MF | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

CNMG160612-MF | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 | ||

| CNMG120404-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 | |

CNMG120408-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 | ||

CNMG120412-OSM | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

| Roughing | CNMG120408-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

CNMG120412-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 | ||

CNMG120416-OPR | 12.9 | 12.7 | 4.76 | 5.16 | 1.6 | ||

CNMG160608-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 | ||

CNMG160612-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 1.2 | ||

CNMG160616-OPR | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 | ||

CNMG190608-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 0.8 | ||

CNMG190612-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 1.2 | ||

CNMG190616-OPR | 19.3 | 19.05 | 6.35 | 7.94 | 1.6 | ||

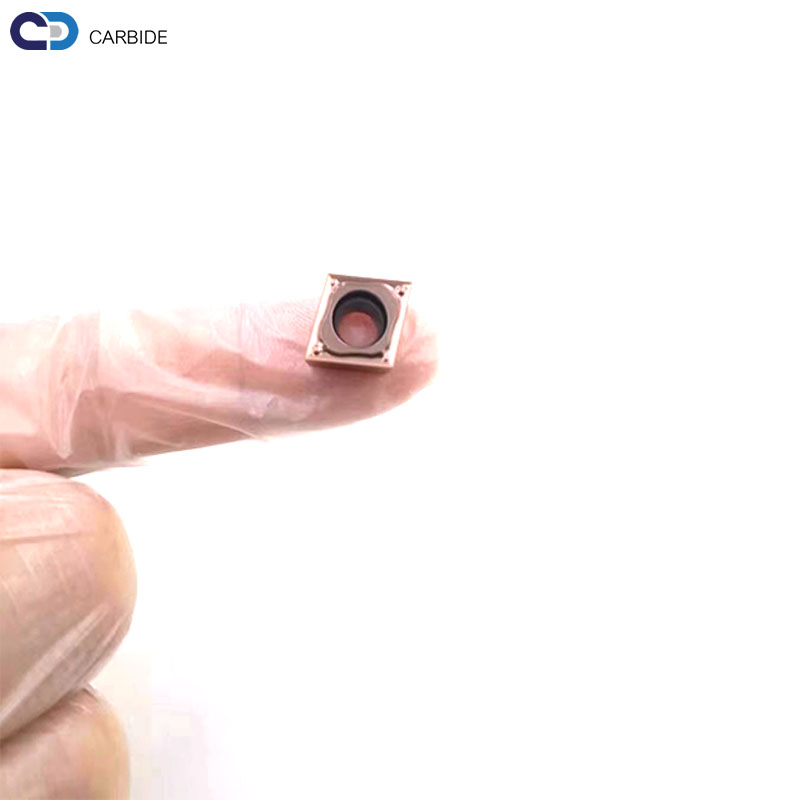

3. product show:

5.Grade:

| Grade for Turning Inserts | ||||

| GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

| CD8025 | CVD | golden yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. MT-TiCN+Al2O3+TiN coating has very good surface quality and help to recognize wear easily. It is suitable for semi-finishing and finishing steel machining. |

| (MT-TiCN+Al2O3+TiN) | ||||

| CD8125 | CVD | black | P10-P40 | The carbide substrate have mild cobalt content and high cubic content, combining with thick TiCN and Al2O3, treated by sepcial technology after coating treatment, which gives inserts strong wearing resistance. It is prority for semi-finishing to finishing steel machining. |

| (Multi-TiCN+Al2O3) | ||||

| CD8020 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel. |

| CD8010 | CVD | black | K10-K30 | The medium-coarse substrate combine with thick TiCN and textured Al2O3, after special coating treatment, it has strong |

| (thick TiCN+ textured Al2O3) | wear-resistance. The grade is suitable for high-speed semi-finishing cast iron turning under stable working condition. | |||

Maswali Yanayoulizwa Mara kwa Mara

1) Ninaweza kupata bei lini?

Kwa kawaida tunanukuu ndani ya saa 24 baada ya kupata uchunguzi wako. Ikiwa una haraka sana kupata bei, tafadhali tupigie simu au utuambie katika barua pepe yako ili tuzingatie swali lako kipaumbele.

2) Ninawezaje kupata sampuli ili kuangalia ubora wako?

Baada ya uthibitisho wa bei, unaweza kuhitaji sampuli ili kuangalia ubora wetu. Iwapo unahitaji tu sampuli tupu ili kuangalia muundo na ubora wa karatasi, tutakupa sampuli bila malipo, mradi tu unamudu usafirishaji wa moja kwa moja.

3) Je, ninaweza kutarajia kupata sampuli kwa muda gani?

Baada ya kulipa sampuli ya malipo na kututumia faili zilizothibitishwa, sampuli zitakuwa tayari kutumwa baada ya siku 3-7. Sampuli zitatumwa kwako kupitia Express na kuwasili katika siku 3-7 za kazi. Unaweza kutumia akaunti yako ya Express au ulipe mapema ikiwa huna akaunti.

4) Utaratibu wote unatekelezwa kwa muda gani?

Baada ya kuweka agizo, wakati wa kushughulikia uzalishaji ni kama siku 20-25. Tunahitaji siku 7 kuandaa vitu vyote kisha siku 15 kwa utengenezaji.

5) Vipi kuhusu tarehe ya usafirishaji na utoaji?

Kwa kawaida sisi hutumia usafirishaji kusafirisha bidhaa. Ni takriban siku 7-25. Pia inategemea uko wapi na bandari gani. Inaweza kuwa fupi zaidi ikiwa unahitaji kutuma bidhaa kama vile za Asia. Ikiwa kuna dharura fulani tunaweza kutuma bidhaa kupitia air Express, mradi tu unamudu gharama za trafiki.

6) Je, wewe ni kampuni ya biashara au mtengenezaji?

Sisi ni watengenezaji wa kitaalamu. Sisi sio tu tunamiliki kiwanda chetu cha zana, lakini pia tuna kiwanda cha kaboni kilichotiwa simenti.

7) Kiwanda chako kiko wapi?

Tunapatikana katika mji wa Zhuzhou, Mkoa wa Hunan., Tungsten carbide base town of China.

8) Je, ninaweza kutarajia kupata sampuli kwa muda gani?

Baada ya kulipa sampuli ya malipo na kututumia faili zilizothibitishwa, sampuli zitakuwa tayari kutumwa baada ya siku 3-7. Sampuli zitatumwa kwako kupitia Express na zitafika baada ya siku 3-5 za kazi. Unaweza kutumia akaunti yako ya Express au ulipe mapema ikiwa huna akaunti.

9) Vipi kuhusu hisa yako?

Tuna bidhaa nyingi kwenye hisa, aina za kawaida na saizi zote ziko kwenye hisa.

10) Je, usafirishaji wa bure unawezekana?

Hatutoi huduma ya usafirishaji bila malipo. Tunaweza kuwa na punguzo ikiwa unununua bidhaa nyingi

Jisikie huru kuwasiliana nami:

Aimee

Meneja mauzo

Zhuzhou Chuangde Cemented Carbide Co

215, building 1, International Students Pioneer Park,

TaishanRoad, Wilaya ya Tianyuan, Mji Zhuzhou.

Barua pepe: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688