- Grade: CD8125

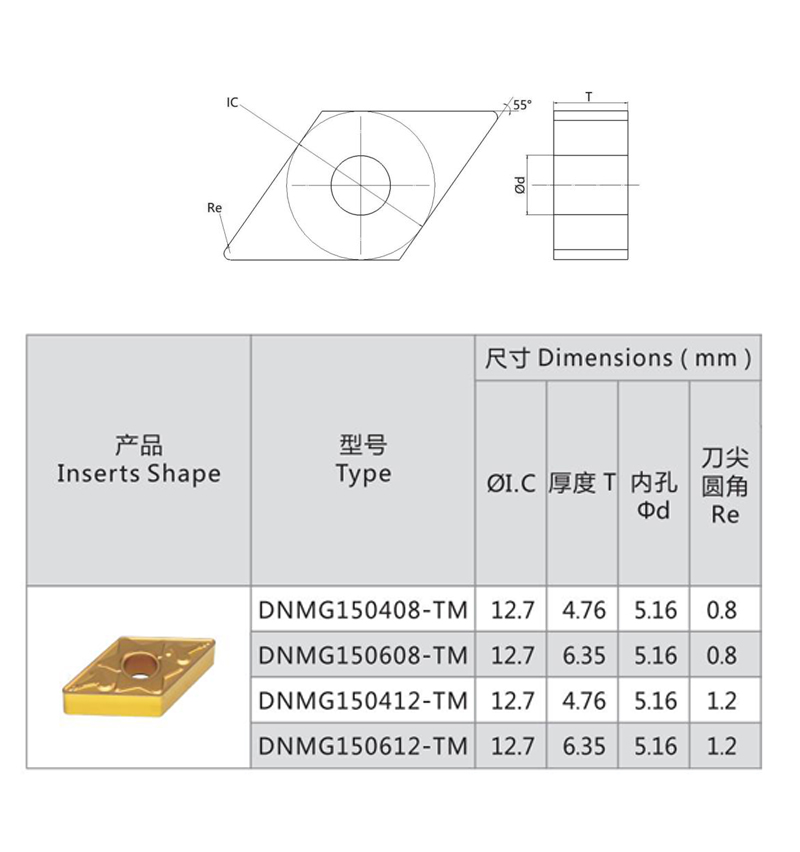

- Model: DNMG150608-TM DNMG150612-TM

- Application: CNC Lathe Machine

- Cutting Condition: High Precision Finishing Cutting

MAELEZO

DNMG Carbide Cutting Inserts DNMG150608-TM DNMG150612-TM CNC Lathe Turning Inserts for Steel General machining

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

Maswali Yanayoulizwa Mara kwa Mara

1) Ninaweza kupata bei lini?

Kwa kawaida tunanukuu ndani ya saa 24 baada ya kupata uchunguzi wako. Ikiwa una haraka sana kupata bei, tafadhali tupigie simu au utuambie katika barua pepe yako ili tuzingatie swali lako kipaumbele.

2) Ninawezaje kupata sampuli ili kuangalia ubora wako?

Baada ya uthibitisho wa bei, unaweza kuhitaji sampuli ili kuangalia ubora wetu. Iwapo unahitaji tu sampuli tupu ili kuangalia muundo na ubora wa karatasi, tutakupa sampuli bila malipo, mradi tu unamudu usafirishaji wa moja kwa moja.

3) Je, ninaweza kutarajia kupata sampuli kwa muda gani?

Baada ya kulipa sampuli ya malipo na kututumia faili zilizothibitishwa, sampuli zitakuwa tayari kutumwa baada ya siku 3-7. Sampuli zitatumwa kwako kupitia Express na kuwasili katika siku 3-7 za kazi. Unaweza kutumia akaunti yako ya Express au ulipe mapema ikiwa huna akaunti.

4) Utaratibu wote unatekelezwa kwa muda gani?

Baada ya kuweka agizo, wakati wa kushughulikia uzalishaji ni kama siku 20-25. Tunahitaji siku 7 kuandaa vitu vyote kisha siku 15 kwa utengenezaji.

5) Vipi kuhusu tarehe ya usafirishaji na utoaji?

Kwa kawaida sisi hutumia usafirishaji kusafirisha bidhaa. Ni takriban siku 7-25. Pia inategemea uko wapi na bandari gani. Inaweza kuwa fupi zaidi ikiwa unahitaji kutuma bidhaa kama vile za Asia. Ikiwa kuna dharura fulani tunaweza kutuma bidhaa kupitia air Express, mradi tu unamudu gharama za trafiki.

6) Je, wewe ni kampuni ya biashara au mtengenezaji?

Sisi ni watengenezaji wa kitaalamu. Sisi sio tu tunamiliki kiwanda chetu cha zana, lakini pia tuna kiwanda cha kaboni kilichotiwa simenti.

7) Kiwanda chako kiko wapi?

Tunapatikana katika mji wa Zhuzhou, Mkoa wa Hunan., Tungsten carbide base town of China.

8) Je, ninaweza kutarajia kupata sampuli kwa muda gani?

Baada ya kulipa sampuli ya malipo na kututumia faili zilizothibitishwa, sampuli zitakuwa tayari kutumwa baada ya siku 3-7. Sampuli zitatumwa kwako kupitia Express na zitafika baada ya siku 3-5 za kazi. Unaweza kutumia akaunti yako ya Express au ulipe mapema ikiwa huna akaunti.

9) Vipi kuhusu hisa yako?

Tuna bidhaa nyingi kwenye hisa, aina za kawaida na saizi zote ziko kwenye hisa.

10) Je, usafirishaji wa bure unawezekana?

Hatutoi huduma ya usafirishaji bila malipo. Tunaweza kuwa na punguzo ikiwa unununua bidhaa nyingi

Jisikie huru kuwasiliana nami:

Aimee

Meneja mauzo

Zhuzhou Chuangde Cemented Carbide Co

215, building 1, International Students Pioneer Park,

TaishanRoad, Wilaya ya Tianyuan, Mji Zhuzhou.

Barua pepe: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688