Ukufakwa okufakelweyo: Olona khetho lufanelekileyo kwihlabathi lokusika

Ukujika okufakelweyozizinto zeZixhobo ezisetyenziswa kwi-latheun. Umsebenzi wabo ophambili kukususa umbandela ogqithisileyo ukusuka kwi-Worpiece ngentshukumo ephakathi yokusebenza kunye nokufakwa okusigxina, ngaloo ndlela kulawula umsebenzi ofunekayo kunye nobungakanani. Kufana nesixhobo esibonisa ngokuchanekileyo esinokusika ngezinto ezahlukeneyo kwaye sidlala indima ephambili kwicandelo lemveliso yoomatshini.

Xa kuthelekiswa nezixhobo zesintu, ukufakwa kwe-carbide kufana nezibonelelo zilandelayo

1. Ubunzima obukhulu kwaye banxibe ukunganyangeki:

Ubulukhuni be-carbide buphakame kakhulu kuneso sezixhobo zesiko, ezinje ngentsimbi ephakamileyo. Oku kuvumela ukutshintsha kwe-carbide kufana ukugcina ubugqwirha obuhle ngexesha lenkqubo yokusika kunye nokuxhathisa ukunxiba kwezinto zomsebenzi kwibala, ngaloo ndlela kwandisa ubomi benkonzo. Umzekelo, xa kusenziwa izixhobo ezinzima ezinobunzima obuphezulu njengentsimbi yentsimbi kunye nentsimbi eqingqiweyo, impahla yokunxiba icacile kakhulu, inokulondoloze ukusebenza rhoqo, kunye nokuphucula ukusebenza kakuhle.

2. Amandla aphezulu kunye nobunzima:

Izixhobo ze-carbide azikho kuphela, kodwa zinamandla okuthile kunye nobunzima. Ukuvula, banokumelana namandla amakhulu okukhulu kunye nemikhosi yefuthe, kwaye ayihambelani ekuchitheni nasekuqhekezweni. Ngokwahlukileyo, izixhobo zeStoel zeStowel zithambekele ekungcungcuthekise nasemonakalo xa ziphantsi kwemithwalo enkulu, echaphazela ukuchaneka kokulungiswa nokusebenza kwemveliso.

I-3. Uzinzo oluhle kakhulu lobushushu:

Inani elikhulu lobushushu liya kuveliswa ngexesha lokujika, lenze ukuba iqondo lobushushu lesixhobo linyuke. I-carbide yamandla inamamela obushushu obuphakamileyo kunye nokuzinza kobushushu, isenokugcina iipropathi ezinobuchule kumaqondo obushushu aphezulu, kwaye akukho lula ukuthambisa okanye ukuthoba ngenxa yobushushu obuphezulu. Oku kufaka i-carbide ye-carbide ethengisayo ukuba iguqulwe kakuhle phantsi kokusika isantya esiphezulu, ukusikwa esomileyo kunye nezinye iimeko zomsebenzi, kwaye zinokuqinisekisa ukwenziwa komgangatho kunye nokuchaneka.

4. Ukuchaneka okuphezulu kunye nokusebenza okuhle:

Ukufakelwa kwemveliso ukufaka i-Carbide ye-Carbide ephezulu kuphezulu, kwaye ukuchaneka kobuso, ukuchaneka kobume, ukuchaneka kunye nomgangatho womda wamabala kunokuqinisekisiwe. Oku kwenza ukuba amabala afezekise ekunqunyulweni ngokuthe ngqo ngexesha lokusika, kwaye imisebenzi esetyenzwayo iye yasebenza ukuba ichanekile kwaye ilunge kakhulu. Kwangelo xesha, umda osikiweyo wokufakwa kwe-carbide ye-carbide right kwaye ukuchasana nokusika kuncinci, okunokunciphisa amandla okusika kunye nokusika amandla izixhobo, kunye nokuphucula ukusebenza kakuhle.

5. Uluhlu olubanzi lwezicelo:

Ukufakwa kwe-carbide ye-carbide kunokukhetha izixhobo ezizahlukileyo zedle, ubungakanani kunye neemfuno ezahlukeneyo zokulungisa, kubandakanya intsimbi, i-Iron engagungqiyo, nokuba yinto engekhoyo.

Imeko yesicelo

1.Roughing:

Kwinqanaba le-furing, ukujika i-kufan isetyenziswa ikakhulu ukususa ngokukhawuleza izixa ezikhulu. Ngeli xesha, faka imiphetho emikhulu yokusika kunye nobunzima obuqinileyo zihlala zikhethiwe, ezinjengeeffit-scar ezinkulu ze-carbide. Oku kufaka i-kufan kungakwazi ukumelana namandla amakhulu okusika kwaye kusebenzise ubunzulu bokusika kunye nokutya ukuphucula ukusebenza kakuhle. Umzekelo, xa kuphumelela amabala amathuba amakhulu eshaft, ukufaka ukufaka i-raft rives kungasusa ngokukhawuleza izinto ezigqithisileyo kwaye enze iprofayili yokusebenza.

2.Semi-finishing:

Inqanaba lokugqitha kukuphucula ukuqhubela phambili ukuchaneka komgangatho kunye nomgangatho womsebenzi wesiseko sokuqonda. Ngeli xesha, ukuguqulwa kokufakwa okhethiweyo kufuneka kube nokusika uzinzo kunye nokuchaneka komda, okoNjengoko i-Debide ye-DAMOND-Fide. Ngokunciphisa ngokufanelekileyo ngokufanelekileyo iqondo lokudalwa kunye nexabiso lokutya, umsebenzi wokusebenza usetyenzwa kusetyenziswa umda wokuchaneka okuphezulu weflow ukuze ulungiselele ukugqiba.

3.Finishing:

Ukugqitywa kufuna ukufaka ukufaka ukufaka ukuze ukwazi ukuqhubekeka ukuchaneka okuphezulu, okuphakathi kwenqanaba eliphantsi. Ngokubanzi, amagqabi abukhali kunye nokuchaneka okuphezulu kukhethiwe, njengokufakwa kwe-ceramic okanye ukufaka i-carbide efaka iingubo ezintle. Kweli nqanaba, ireyithi yexabiso elisikiweyo kunye nereyithi yondla incinci kakhulu, kwaye i-blade isetyenziselwa ukwenza ukusika i-cerpiece kumhlaba wokusebenza. Umzekelo, xa kuqhubela phambili icandelo eliphezulu lokuchaneka njengemikhono, ukugqiba kwebala kunokwenza ukuba i-subriece ifikelela kwi-ra0.8μm okanye ngaphantsi.

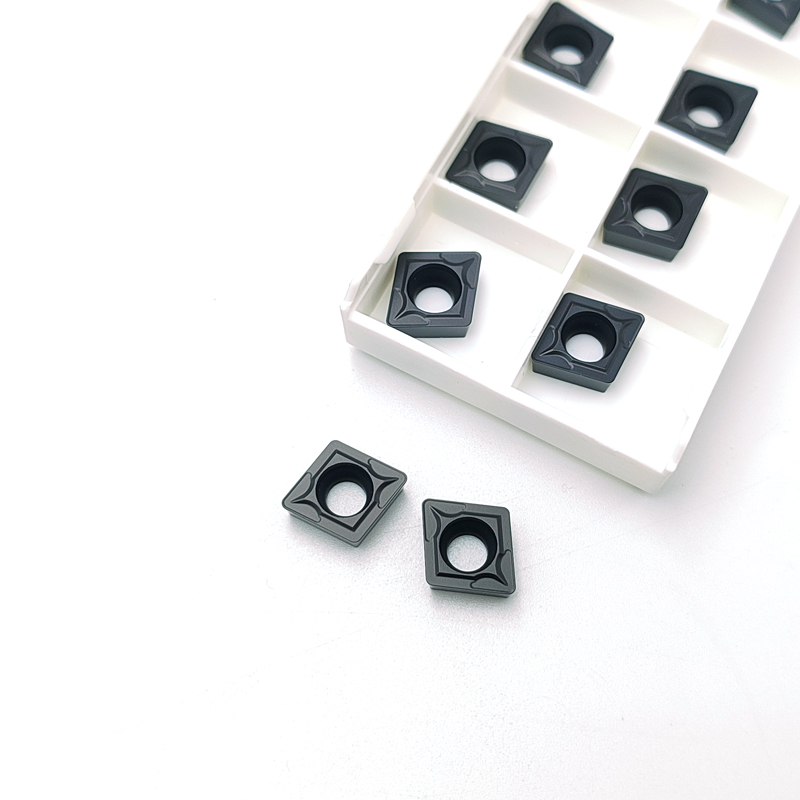

Iimodeli

1.Ukufunyanwa kwezinto:ikakhulu i-carbide ye-carbide ijika ii-Blades, i-Ceramic ijika ii-blades, i-ceramic ye-ceramic ye-cerbic, njl njl. Iijika ze-ceramic ze-ceramic zinobuqili obuphezulu kwaye zinxibe ukuxhathisa, zilungele ukusika isantya esiphezulu kunye nokulungisa izinto ezinzima; I-ceramic ye-ceramic ye-ceramic idibanisa izibonelelo ze-carbide kunye ne-ceramics, ngokusebenzisa kakuhle ukunqunyulwa kunye nokunganyangeki.

2.Ukuziswa kwakhona ngobume:Abantu abaqhelekileyo banxantathu, isikwere, idayimani, isangqa, njl njl.

3.Ukuzibandakanya ngokusetyenziswa:Kubandakanywa ii-blades zangaphandle, ii-Blade zangaphakathi ezijika ii-blades, ukusika i-Blade, intambo ijika ii-blades, njl njl.

IIMPICISO

I-1.High Jikelele kunye nokuqina:Ukufumana izinto ezahlukeneyo ezibalaseleyo ezinjengobunzima obuphakamileyo, nxiba ngokuchasene nenqanaba eliphezulu lokugqiba ukuqinisekisa ukufunyanwa kwe-chip egudileyo.

Itekhnoloji yeTekhnoloji yokuqinisekisa: Ubukhali buqhutywa kwitekhnoloji yobukrelekrele bobuchwephesha obuphezulu kwaye bomelele ukuqina ngokubanzi kunye nexesha elide lokuphila, kunye nomda wokusika ubukhali kwaye ngaphezulu kokunganyangeki.

I-3.untench ye-Forden kunye ne-Milling elula:I-blades ekhethekileyo yokuchaphazela ukunciphisa ukunxiba ngokuncipha kwengqungquthela, ngaphantsi kokubangela i-blade inamathela okanye iqhekeza elaphukileyo.

Imveliso yethu yeMveliso