Zisetyenziselwa ntoni ukufaka i-carbide?

Ukufakwa kweCarbide kudlala indima ebalulekileyo kwimisebenzi yomatshini yale mihla kuwo wonke amashishini ahlukeneyo, ngenxa yobuchule babo.

Ukuqina okukhethekileyo, ukuguquguquka, kunye nokuchaneka. Ezi zifakelo zisetyenziselwa ubuninzi bokusika kunye nokubunjwa

iinkqubo, ukunika iingenelo ezibalulekileyo phezu izixhobo zentsimbi zemveli ngesantya esiphezulu. Kweli nqaku, siza kuhlolisisa

usetyenziso, izibonelelo, kunye neengqalelo eziphambili ezinxulumene nokufakwa kwe-carbide.

Intshayelelo kwiCarbide Insert:

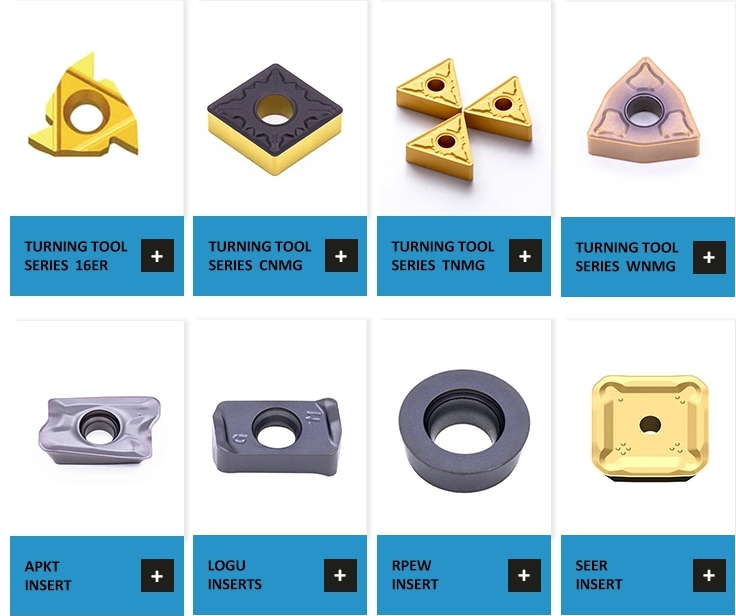

UChuangde ngumvelisi kunye nomthengisi wezixhobo zokusika i-carbide kunye neemveliso ezinxulumene nazo eziseZhuzhou, eChina. Inkampani ivelisa izixhobo zokusika i-carbide ezisetyenziswa kumatshini kunye neenkqubo zesinyithi zokuqina kunye nokunganyangeki. Ezi ziquka izinto ezifakelwayo, ii-end Mills, iidrill, ii-reamers, i-burr, kunye nezixhobo ezizodwa. Iimveliso zayo zenzelwe iMetal working.We inikezela ngamaxabiso aphezulu akhuphisanayo kunye neemveliso ezisemgangathweni. Ikhona, isampuli yasimahla.

Usetyenziso:

Ufakelo lweCarbide olusetyenziswa kakhulu ekujikeni umsonto, ukusika kunye nokugroova njalo njalo. Lukhetho olulungileyo lokurhabaxa, ukugqiba, ukugqibezela.umatshini jikelele wentsimbi, intsimbi engatyiwa kunye nentsimbi etyhidiweyo.

1. Ukujika kunye nokugaya: Ufakelo lweCarbide lusetyenziswa kakhulu ekujikeni nakwimisebenzi yokugaya kwindawo ebanzi

uluhlu lwezixhobo, kubandakanywa intsimbi, insimbi engenasici, intsimbi, i-aluminium, kunye ne-alloys ephezulu yokushisa.

Bagqwesa ekudaleni iicontours ezichanekileyo, imisonto, kunye nemigangatho enomphezulu ongaphezulu.

2. Ukugrumba kunye nokukruqula: Ukufakwa kweCarbide kuqeshwe kwi-drilling kunye nezicelo ezidikayo zokudala imingxuma

ubunzulu kunye nobukhulu obahlukeneyo. I-conductivity ephezulu ye-thermal kunye nokuchasana ne-deformation kuqinisekisa

ukusebenza okungaguquguqukiyo nakwiimeko zokomba ezinomngeni.

3. Umsonto: Ukufakwa kwe-Carbide kukhethwa kwimisebenzi yokuthunga ngenxa yokukwazi ukugcina ibukhali

ukusika imiphetho yokusetyenziswa ixesha elide, okukhokelela kwiiprofayili zemisonto ezichanekileyo kunye nokuncipha kokunxiba kwesixhobo.

4. Ukugroova kunye nokwahlula: Ufakelo lweCarbide luququzelela ukusebenza ngokufanelekileyo kwe-grooving kunye nokwahlukana, okwenza ukuba

ukudalwa kwemijelo emxinwa kunye nokwahlulwa kwezinto zokusebenza kunye nenkcitho encinci yezinto.

5. High-Speed Machining (HSM): Ukufakwa Carbide ziyimfuneko kwizicelo HSM apho izinto ngokukhawuleza

amazinga okususwa abalulekile. Ubunzima babo obuphezulu kunye nokuzinza kwe-thermal kwenza ukuba isantya sokusika siqhubeke

kunye namazinga esondlo, ukwandisa imveliso kunye nokusebenza kakuhle kweendleko.

Izinto eziluncedo:

1. Ubomi besixhobo esandisiweyo: Ukufakwa kweCarbide kubonisa ubomi besixhobo obude kakhulu xa kuthelekiswa nesantya esiphezulu esiqhelekileyo.

izixhobo zentsimbi, ukunciphisa utshintsho lwesixhobo kunye nexesha lokuphumla.

2. Imveliso ephuculweyo: Ukusebenza okuphezulu kokusika kunye nokuxhatshazwa kokugqoka kokufakwa kwe-carbide kubangela

Izantya zoomatshini ezikhawulezayo kunye nokwanda kokuphuma kwemveliso, ukuphucula imveliso iyonke.

3. UkuGqibezela koMphezulu oPhuculweyo: Ukufakwa kweCarbide kuvelisa umphezulu ogudileyo ogqityiweyo onama-burrs amancinci kunye neziphene,

ukuphelisa imfuno yokugqiba imisebenzi yesibini kunye nokuphucula umgangatho wenxalenye.

4. Ukuguquguquka: Ukufakwa kweCarbide kufumaneka kuluhlu olubanzi lweejometri, iingubo, kunye namabanga alungiselelwe

usetyenziso oluthile lomatshini, olunikezela ngezinto ezininzi kunye nokuguquguquka ekukhetheni izixhobo.

5. Ukugcinwa kweendleko: Nangona ixabiso labo lokuqala liphezulu, ukufakwa kwe-carbide kuzisa ixabiso eliphezulu kakhulu kunexabiso labo.

ixesha lokuphila ngenxa yokuncipha kweendleko zezixhobo, imveliso eyandisiweyo, kunye nexabiso eliphantsi lecandelo ngalinye lomatshini.

Ukuqukumbela, ukufakwa kwe-carbide kumela ilitye lembombo letekhnoloji yomatshini yanamhlanje, ebonelela ngokusebenza okungenakulinganiswa, ukuguquguquka, kunye nokusebenza kakuhle kweendleko kuluhlu oluhlukeneyo lwezicelo.