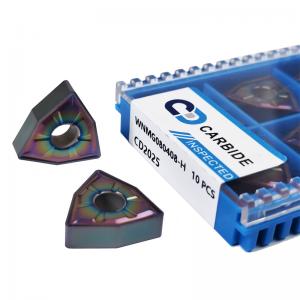

- Materials: 100% raw material tungsten carbide

- Coating:PVD/CVD

- Use for General machining Steel, Mould steel, Cast iron, Alloy steel

- Service: OEM & ODM

Inkcazo

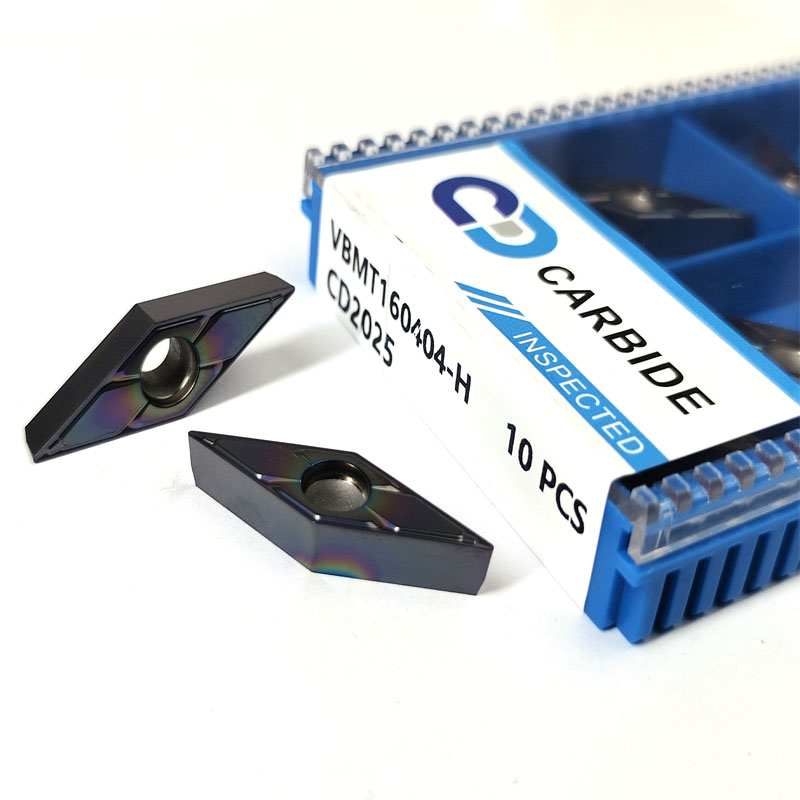

VBMT160404-H PVD Coated Carbide Insert | Hard Steel Turning Tool | High Wear Resistance

Product Description:

The VBMT160404-H is a premium PVD-coated carbide turning insert specially designed for Hard Steel machining applications. Featuring advanced TiAlN/AlCrN multi-layer coating technology, this high-performance insert delivers exceptional wear resistance and thermal stability for superior machining results.

Applications:

Ideal for machining various stainless steels including:

• Austenitic grades (304, 316, 317L)

• Duplex stainless steels (2205, 2507)

• Martensitic and precipitation-hardening grades

Why Choose Our Insert?

40% longer tool life compared to standard grades

Excellent built-up edge prevention

Consistent performance in continuous and interrupted cuts

ISO certified quality assurance

Available in standard packaging of 10 inserts/box. Contact us today for technical

FAQ

1) Ndingalifumana nini ixabiso?

Sidla ngokucaphula kwiiyure ezingama-24 emva kokuba sifumene i-inquiry.Ukuba ungxamiseke kakhulu ukufumana ixabiso, nceda usitsalele umnxeba okanye usixelele kwi-imeyile yakho ukuze siwuthathele ingqalelo umbuzo wakho.

2) Ndingayifumana njani isampuli ukujonga umgangatho wakho?

Emva kokuqinisekiswa kwexabiso, unokufuna iisampuli ukujonga umgangatho wethu. Ukuba ufuna nje isampulu engenanto ukujonga uyilo kunye nomgangatho wephepha, siya kukubonelela ngesampulu simahla, ukuba nje unakho ukuthenga iimpahla ezicacileyo.

3) Ndingalindela ixesha elingakanani ukufumana isampuli?

Emva kokuba uhlawule intlawulo yesampuli kwaye usithumele iifayile eziqinisekisiweyo, iisampuli ziya kuba zilungele ukuhanjiswa kwiintsuku ze-3-7. Iisampuli ziya kuthunyelwa kuwe nge-express kwaye zifike ngeentsuku ezi-3-7 zomsebenzi. Ungasebenzisa i-akhawunti yakho ye-express okanye usihlawule kwangaphambili ukuba awunayo i-akhawunti.

4) Ingaba yonke inkqubo yenziwa ixesha elingakanani?

Emva kokuba ufake iodolo, ixesha lokuphatha imveliso limalunga neentsuku ezingama-20-25. Sidinga iintsuku ezisi-7 ukulungiselela zonke izinto emva koko iintsuku ezili-15 zokwenziwa.

5) Kuthekani ngomhla wokuthutha kunye nokuhanjiswa?

Ngokuqhelekileyo sisebenzisa ukuthunyelwa ukuhambisa iimpahla.Kumalunga ne-7-25 iintsuku.Kwaye kuxhomekeke kwi-coutry kunye ne-port okhoyo.Inokuba mfutshane ukuba ufuna ukuthumela iimpahla ezifana ne-Asian. Ukuba kukho izinto ezingxamisekileyo singazithumela iimpahla nge-air Express, ukuba nje uneendleko zendlela.

6) Ngaba uyinkampani yokurhweba okanye umenzi?

Singabavelisi abaqeqeshiweyo. Asinabanini kuphela umzi-mveliso wezixhobo zethu, kodwa sikwanawo nomzi-mveliso we-carbide onesamente.

7) Uphi umzi-mveliso wakho?

Sizinze kwidolophu yase Zhuzhou, kwiPhondo lase Hunan

I-8) Ndingalindela ixesha elingakanani ukufumana isampuli?

Emva kokuba uhlawule intlawulo yesampuli kwaye usithumele iifayile eziqinisekisiweyo, iisampuli ziya kuba zilungele ukuhanjiswa kwiintsuku ze-3-7. Iisampulu ziya kuthunyelwa kuwe nge-express kwaye zifike ngeentsuku ezi-3-5 zomsebenzi. Ungasebenzisa i-akhawunti yakho ye-express okanye usihlawule kwangaphambili ukuba awunayo i-akhawunti.

9) Kuthekani ngesitokhwe sakho?

Sinemveliso eninzi kwisitokhwe, iintlobo eziqhelekileyo kunye nobukhulu zonke zikhoyo.

10) Ngaba ukuthunyelwa kwamahhala kunokwenzeka?

Asinikezeli ngenkonzo yokuthumela simahla. Sinokuba nesaphulelo ukuba uthenga iimveliso zesixa esikhulu

Nceda uqhagamshelane nam:

Aimee

Umlawuli wentengiso

Zhuzhou Chuangde Cemented Carbide Co

215, building 1, International Students Pioneer Park,

I-TaishanRoad, iSithili se-Tianyuan, iSixeko sase-Zhuzhou.

I-imeyile: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688