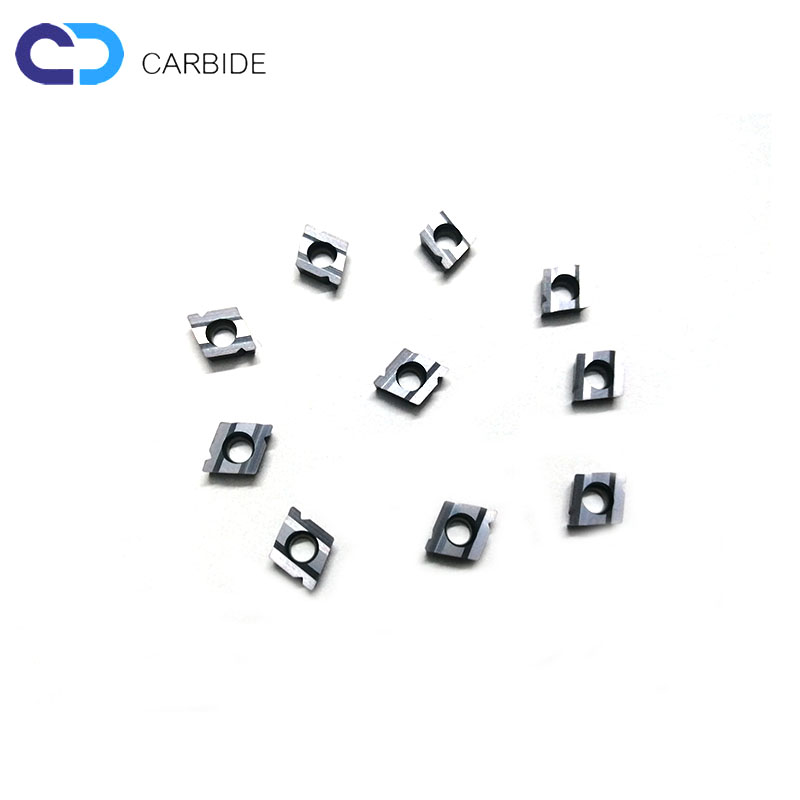

- Grade: P05-P20,M05-M20,K05-K20

- Application: CNC Lathe Machine

- Advantage: High Wear Resistance

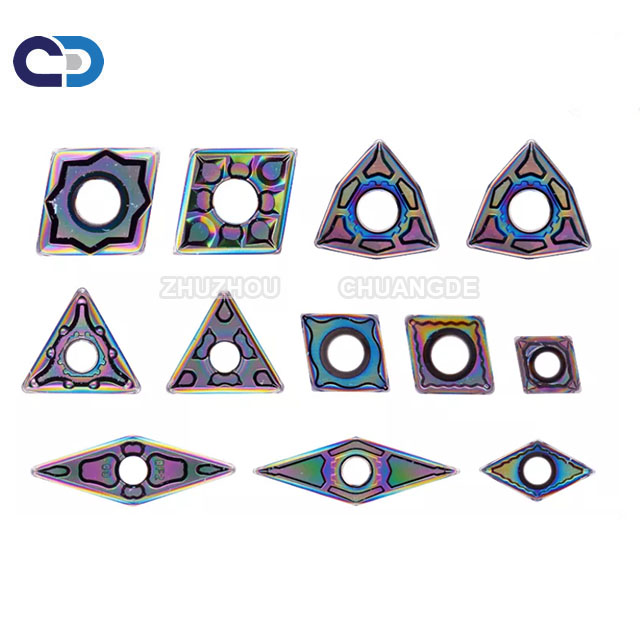

- Item: SEEN1203,CCMT09T304-HQ,SPKN1504EDSKR,CNMG120404,TNMG160408

INKCAZO

ceramic cermet carbide turning inserts lathe For Bearing Steel

Grade and application of Cermet turning insert tools CNC machines

| Grade for Turning Inserts | ||||

| GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

| CD8025 | CVD | golden yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. MT-TiCN+Al2O3+TiN coating has very good surface quality and help to recognize wear easily. It is suitable for semi-finishing and finishing steel machining. |

| (MT-TiCN+Al2O3+TiN) | ||||

| CD8125 | CVD | black | P10-P40 | The carbide substrate have mild cobalt content and high cubic content, combining with thick TiCN and Al2O3, treated by sepcial technology after coating treatment, which gives inserts strong wearing resistance. It is prority for semi-finishing to finishing steel machining. |

| (Multi-TiCN+Al2O3) | ||||

| CD8020 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel. |

| CD8010 | CVD | black | K10-K30 | The medium-coarse substrate combine with thick TiCN and textured Al2O3, after special coating treatment, it has strong |

| (thick TiCN+ textured Al2O3) | wear-resistance. The grade is suitable for high-speed semi-finishing cast iron turning under stable working condition. | |||

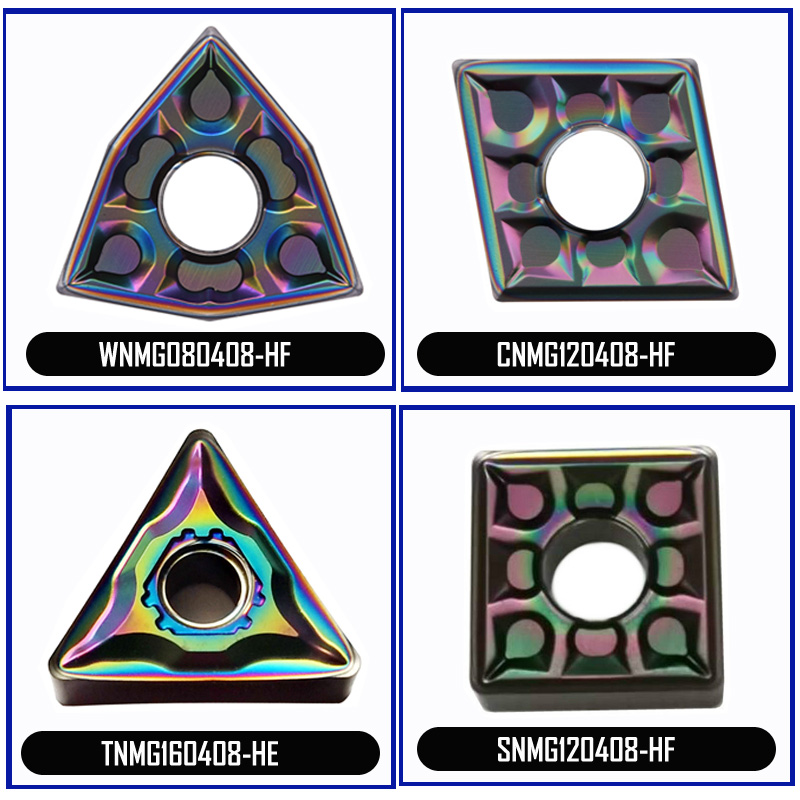

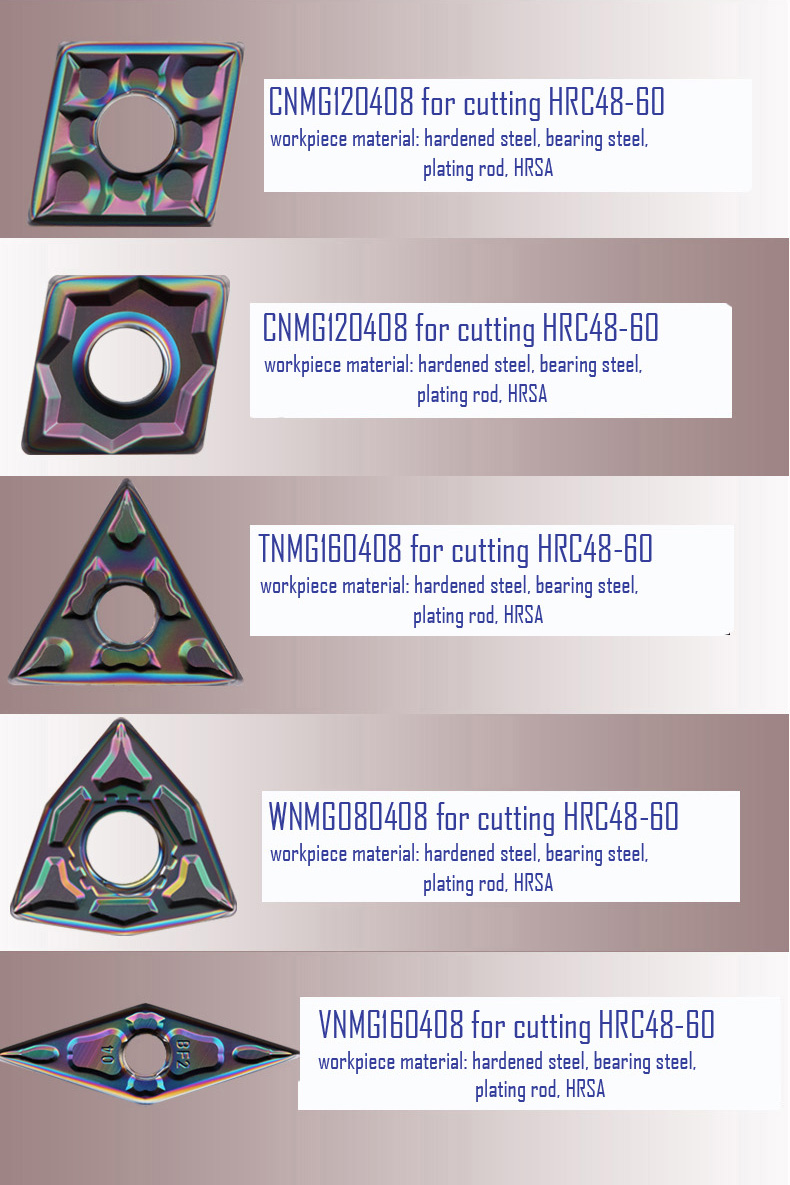

Carbide inserts for HRC48-60 Steel、hardened steel、bearing steel and HRSA

Cermer inserts turing tools for HRC 48-60 Steel

Colorful coating with High wear resistance cermet inserts

FAQ

1) Ndingalifumana nini ixabiso?

Sidla ngokucaphula kwiiyure ezingama-24 emva kokuba sifumene i-inquiry.Ukuba ungxamiseke kakhulu ukufumana ixabiso, nceda usitsalele umnxeba okanye usixelele kwi-imeyile yakho ukuze siwuthathele ingqalelo umbuzo wakho.

2) Ndingayifumana njani isampuli ukujonga umgangatho wakho?

Emva kokuqinisekiswa kwexabiso, unokufuna iisampuli ukujonga umgangatho wethu. Ukuba ufuna nje isampulu engenanto ukujonga uyilo kunye nomgangatho wephepha, siya kukubonelela ngesampulu simahla, ukuba nje unakho ukuthenga iimpahla ezicacileyo.

3) Ndingalindela ixesha elingakanani ukufumana isampuli?

Emva kokuba uhlawule intlawulo yesampuli kwaye usithumele iifayile eziqinisekisiweyo, iisampuli ziya kuba zilungele ukuhanjiswa kwiintsuku ze-3-7. Iisampuli ziya kuthunyelwa kuwe nge-express kwaye zifike ngeentsuku ezi-3-7 zomsebenzi. Ungasebenzisa i-akhawunti yakho ye-express okanye usihlawule kwangaphambili ukuba awunayo i-akhawunti.

4) Ingaba yonke inkqubo yenziwa ixesha elingakanani?

Emva kokuba ufake iodolo, ixesha lokuphatha imveliso limalunga neentsuku ezingama-20-25. Sidinga iintsuku ezisi-7 ukulungiselela zonke izinto emva koko iintsuku ezili-15 zokwenziwa.

5) Kuthekani ngomhla wokuthutha kunye nokuhanjiswa?

Ngokuqhelekileyo sisebenzisa ukuthunyelwa ukuhambisa iimpahla.Kumalunga ne-7-25 iintsuku.Kwaye kuxhomekeke kwi-coutry kunye ne-port okhoyo.Inokuba mfutshane ukuba ufuna ukuthumela iimpahla ezifana ne-Asian. Ukuba kukho izinto ezingxamisekileyo singazithumela iimpahla nge-air Express, ukuba nje uneendleko zendlela.

6) Ngaba uyinkampani yokurhweba okanye umenzi?

Singabavelisi abaqeqeshiweyo. Asinabanini kuphela umzi-mveliso wezixhobo zethu, kodwa sikwanawo nomzi-mveliso we-carbide onesamente.

7) Uphi umzi-mveliso wakho?

Sizinze kwidolophu yase Zhuzhou, kwiPhondo lase Hunan

I-8) Ndingalindela ixesha elingakanani ukufumana isampuli?

Emva kokuba uhlawule intlawulo yesampuli kwaye usithumele iifayile eziqinisekisiweyo, iisampuli ziya kuba zilungele ukuhanjiswa kwiintsuku ze-3-7. Iisampulu ziya kuthunyelwa kuwe nge-express kwaye zifike ngeentsuku ezi-3-5 zomsebenzi. Ungasebenzisa i-akhawunti yakho ye-express okanye usihlawule kwangaphambili ukuba awunayo i-akhawunti.

9) Kuthekani ngesitokhwe sakho?

Sinemveliso eninzi kwisitokhwe, iintlobo eziqhelekileyo kunye nobukhulu zonke zikhoyo.

10) Ngaba ukuthunyelwa kwamahhala kunokwenzeka?

Asinikezeli ngenkonzo yokuthumela simahla. Sinokuba nesaphulelo ukuba uthenga iimveliso zesixa esikhulu

Nceda uqhagamshelane nam:

Aimee

Umlawuli wentengiso

Zhuzhou Chuangde Cemented Carbide Co

215, building 1, International Students Pioneer Park,

I-TaishanRoad, iSithili se-Tianyuan, iSixeko sase-Zhuzhou.

I-imeyile: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688