404 IPHEPHA IXESHA

- Ikhaya

- |- Ngathi

- |- Iimveliso

- |-- Ukujika Ufaka izixhobo

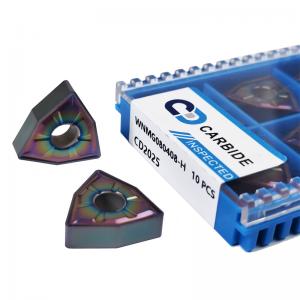

- |--- Ukuguqula izixhobo zokuLungisa iNsimbi

- |--- Ukuguqula izixhobo zeStainless Steel Processing

- |--- Ukuguqula izixhobo zeCast iron Processing

- |--- Drilling Insert

- |--- Ukuguqula izixhobo zeAluminium Processing

- |--- CBN & PCD Inserts

- |--- Cermet Insets

- |--- Umphathi wesixhobo se-CNC

- |--- Ukufakwa koqobo

- |-- IiMill zokuphela kweCarbide

- |--- Izixhobo zokusika kwamanzi

- |--- 2/4 Corner Radius End Mills

- |--- 2/4 Flutes Ball Nose End Mills

- |--- 2/4 Flutes Flat End Mills

- |--- I-HRC55 ye-Square End Mills yokusika

- |--- Roughing End Mills

- |--- I-Chamfer end Mill

- |--- UCwangciso lweCarbide eSolid

- |--- Iinqwelo zeCarbide

- |-- Cermet End Mill

- |- Khuphela

- |-- Uxwebhu loncedo

- |-- ukhuphelo lwefayile

- |- Iindaba

- |-- Inkampani entsha

- |--- ISebe leendaba

- |-- Iindaba zeshishini

- |- Ifoto

- |-- I-albhamu yeefoto zabasebenzi

- |-- Ityala lomthengi

- |- Qhagamshelana nathi