404 oju-iwe aṣiṣe

- Ile

- |- Nipa re

- |- Awọn ọja

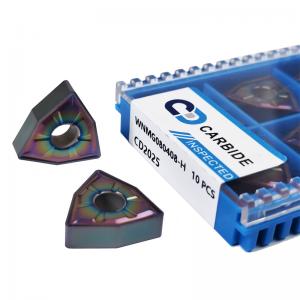

- |-- Awọn irinṣẹ Awọn ifibọ titan

- |--- Titan-irinṣẹ fun Irin Processing

- |--- Awọn irinṣẹ titan fun Ṣiṣeto Irin Alagbara

- |--- Awọn irinṣẹ titan fun Ṣiṣẹda Irin Simẹnti

- |--- Awọn ifibọ liluho

- |--- Awọn irinṣẹ titan fun Ṣiṣe Aluminiomu

- |--- CBN & Awọn ifibọ PCD

- |--- Awọn ifibọ Cermet

- |--- Dimu Ọpa CNC

- |--- Awọn ifibọ atilẹba

- |-- Ri to Carbide Ipari Mills

- |--- Awọn irinṣẹ gige gige

- |--- 2/4 Igun Radius Ipari Mills

- |--- 2/4 Flute Ball Imu Ipari Mills

- |--- 2/4 Flutes Flat Ipari Mills

- |--- HRC55 Square End ọlọ fun Ige

- |--- Roughing Ipari Mills

- |--- Chamfer opin ọlọ

- |--- Ri to Carbide Drills

- |--- Carbide Reamers

- |-- Cermet Ipari Mill

- |- Gbigba lati ayelujara

- |-- Iwe iranlọwọ

- |-- download faili

- |- Iroyin

- |-- Ile-iṣẹ tuntun

- |--- Department of iroyin

- |-- Awọn iroyin ile-iṣẹ

- |- aworan

- |-- Abáni Fọto album

- |-- Onibara nla

- |- Pe wa