- Material: Cermet carbide

- Processing: Finishing

- Appllication: Steel and Stainless Steel Processing

Apejuwe

Product description

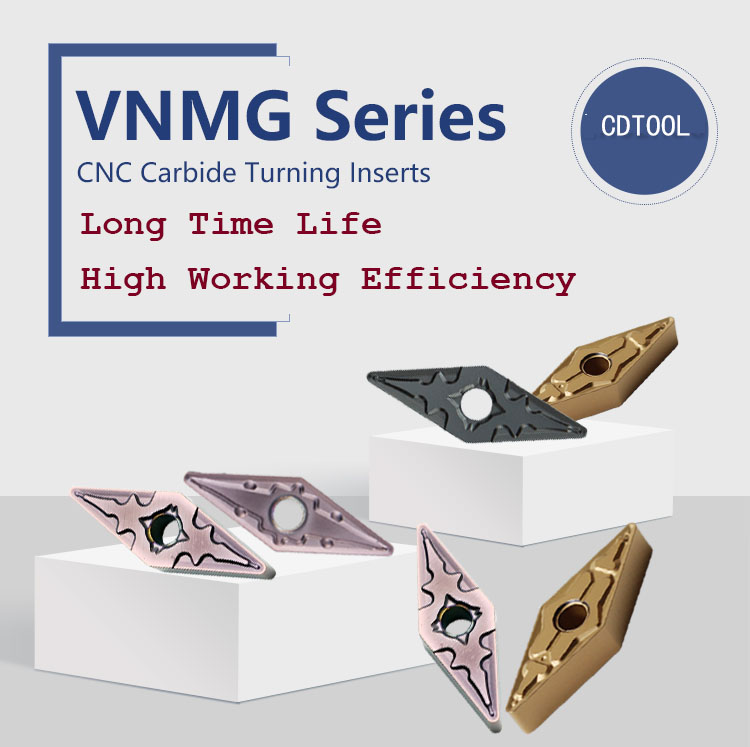

CNC machine turning tools carbide cermet inserts VNMG for Metal Steel and Stainless Steel

1. Basic Information:

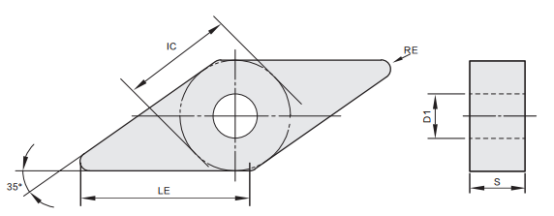

2. Design Drawing:

Insert Shape |

Type | Dimension | |||||

LE |

IC |

S |

D1 |

RE | |||

| Finishing | VNMG160404-OPF | 16.6 | 9.525 | 4.76 | 3.81 | 0.4 |

VNMG160408-OPF | 16.6 | 9.525 | 4.76 | 3.81 | 0.8 | ||

| VNMG160404-MSF | 16.6 | 9.525 | 4.76 | 3.81 | 0.4 | |

Semi Finishing | VNMG160404-OPM | 16.6 | 9.525 | 4.76 | 3.81 | 0.4 | |

VNMG160408-OPM | 16.6 | 9.525 | 4.76 | 3.81 | 0.8 | ||

VNMG160412-OPM | 16.6 | 9.525 | 4.76 | 3.81 | 1.2 | ||

| VNMG160404-OMM | 16.6 | 9.525 | 4.76 | 3.81 | 0.4 | |

VNMG160408-OMM | 16.6 | 9.525 | 4.76 | 3.81 | 0.8 | ||

VNMG160408-MF | 16.6 | 9.525 | 4.76 | 3.81 | 0.8 | ||

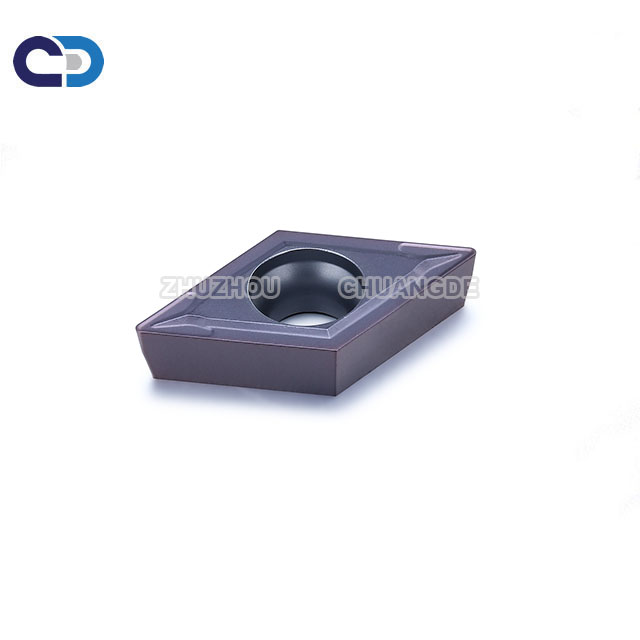

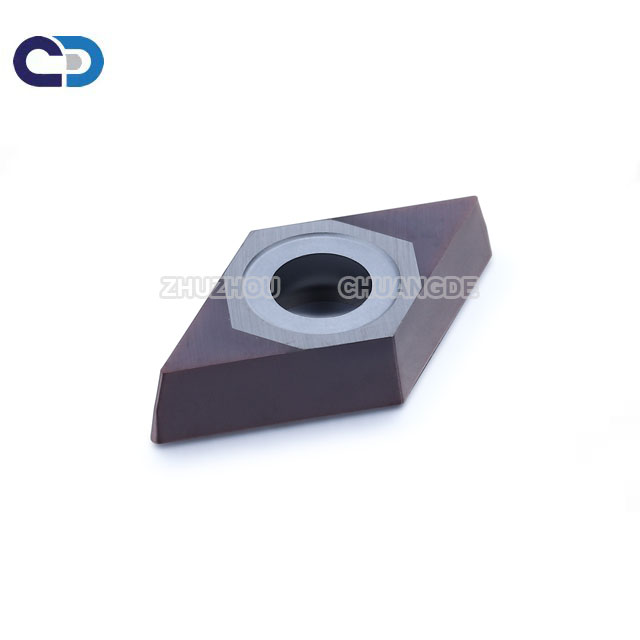

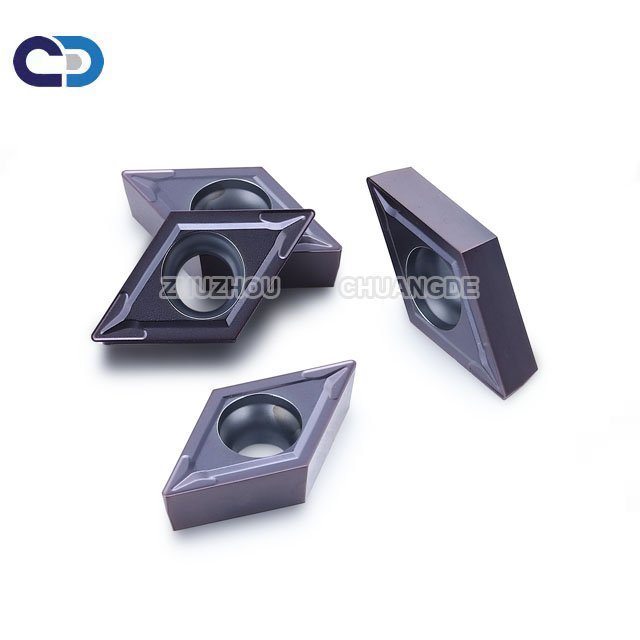

3. Product Show:

4. Grade for Cemented Carbide inserts VNMG type

| Grade for Turning Inserts | ||||

| GRADE | COATING | COLOR | WORKING MATERIAL | APPLICATION |

| CD8025 | CVD | golden yellow | P10-P30 | The carbide substrate have good anti-deformation resistance and toughness. MT-TiCN+Al2O3+TiN coating has very good surface quality and help to recognize wear easily. It is suitable for semi-finishing and finishing steel machining. |

| (MT-TiCN+Al2O3+TiN) | ||||

| CD8125 | CVD | black | P10-P40 | The carbide substrate have mild cobalt content and high cubic content, combining with thick TiCN and Al2O3, treated by sepcial technology after coating treatment, which gives inserts strong wearing resistance. It is prority for semi-finishing to finishing steel machining. |

| (Multi-TiCN+Al2O3) | ||||

| CD8020 | PVD (Silicon+TiAlN) | purple | M10-M30 | Micro WC grain substrate with high Co maintain cutting edge strength and it has smallest coefficient of friction and good nano hardness with good thermal stability silicon coating. The grade is very good for interrupt turning and milling for stainless steel. |

| CD8010 | CVD | black | K10-K30 | The medium-coarse substrate combine with thick TiCN and textured Al2O3, after special coating treatment, it has strong |

| (thick TiCN+ textured Al2O3) | wear-resistance. The grade is suitable for high-speed semi-finishing cast iron turning under stable working condition. | |||

FAQ

1) Nigbawo ni MO le gba idiyele naa?

A maa n sọ laarin awọn wakati 24 lẹhin ti a gba ibeere rẹ.Ti o ba ni iyara pupọ lati gba idiyele naa, jọwọ pe wa tabi sọ fun wa ninu imeeli rẹ ki a le ṣe akiyesi pataki ibeere rẹ.

2) Bawo ni MO ṣe le gba ayẹwo lati ṣayẹwo didara rẹ?

Lẹhin ijẹrisi idiyele, o le nilo fun awọn ayẹwo lati ṣayẹwo didara wa. Ti o ba kan nilo ayẹwo òfo lati ṣayẹwo apẹrẹ ati didara iwe, a yoo fun ọ ni ayẹwo fun ọfẹ, niwọn igba ti o ba ni ẹru ọkọ oju-omi kiakia.

3) Igba melo ni MO le reti lati gba ayẹwo naa?

Lẹhin ti o san idiyele ayẹwo ati firanṣẹ awọn faili ti a fọwọsi, awọn ayẹwo yoo ṣetan fun ifijiṣẹ ni awọn ọjọ 3-7. Awọn ayẹwo naa yoo ranṣẹ si ọ nipasẹ kiakia ati de ni awọn ọjọ iṣẹ 3-7. O le lo akọọlẹ kiakia ti ara rẹ tabi sanwo tẹlẹ wa ti o ko ba ni akọọlẹ kan.

4) Bawo ni pipẹ gbogbo ilana ti n ṣiṣẹ jade?

Lẹhin ti o paṣẹ, akoko mimu iṣelọpọ jẹ nipa awọn ọjọ 20-25. A nilo awọn ọjọ 7 lati ṣeto gbogbo nkan naa lẹhinna awọn ọjọ 15 fun iṣelọpọ.

5) Kini nipa gbigbe ati ọjọ ifijiṣẹ?

Ni deede a lo gbigbe lati gbe awọn ọja naa pada. O jẹ nipa awọn ọjọ 7-25. O tun da lori iru ile-iṣẹ ati ibudo ti o wa. O le jẹ kukuru ti o ba nilo lati firanṣẹ awọn ọja bi Asia. Ti o ba wa diẹ ninu awọn pajawiri a le fi awọn ẹru ranṣẹ nipasẹ afẹfẹ kiakia, niwọn igba ti o ba ni owo-owo ijabọ naa.

6) Ṣe o jẹ ile-iṣẹ iṣowo tabi olupilẹṣẹ?

A ni o wa ọjọgbọn olupese. A ko ni ile-iṣẹ irinṣẹ wa nikan, ṣugbọn tun ni ile-iṣẹ carbide ti simenti.

7) Nibo ni ile-iṣẹ rẹ wa?

A wa ni ilu Zhuzhou, Hunan Province., Tungsten carbide base town of China

8) Igba melo ni MO le reti lati gba ayẹwo naa?

Lẹhin ti o san idiyele ayẹwo ati firanṣẹ awọn faili ti a fọwọsi, awọn ayẹwo yoo ṣetan fun ifijiṣẹ ni awọn ọjọ 3-7. Awọn ayẹwo naa yoo ranṣẹ si ọ nipasẹ kiakia ati de ni awọn ọjọ iṣẹ 3-5. O le lo akọọlẹ kiakia ti ara rẹ tabi sanwo tẹlẹ wa ti o ko ba ni akọọlẹ kan.

9) Bawo ni nipa ọja iṣura rẹ?

A ni awọn ọja ti o tobi pupọ ni iṣura, awọn oriṣi deede ati awọn titobi gbogbo wa ni iṣura.

10) Ṣe ifijiṣẹ ọfẹ ṣee ṣe?

A ko funni ni iṣẹ gbigbe ọfẹ. A le ni ẹdinwo ti o ba ra ọja ti o tobi pupọ

Lero lati kan si mi:

Aimee

Alabojuto nkan tita

Zhuzhou Chuangde Cemented Carbide Co. Ltd

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan Agbegbe, Zhuzhou Ilu.

Imeeli: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype: 0086 13786352688