404 錯誤頁面

- 家

- |- 關於我們

- |- 產品

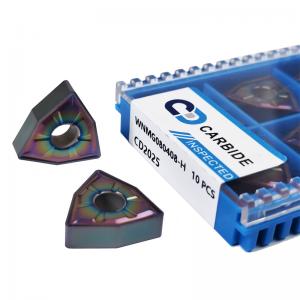

- |-- 車削刀片工具

- |--- 鋼材加工用車刀

- |--- 不銹鋼加工車刀

- |--- 鑄鐵加工用車刀

- |--- 鑽孔刀片

- |--- 鋁加工車刀

- |--- CBN 和 PCD 刀片

- |--- 金屬陶瓷刀片

- |--- CNC刀架

- |--- 原創插頁

- |-- 整體硬質合金立銑刀

- |--- 木工切割工具

- |--- 2/4 角半徑立銑刀

- |--- 2/4 刃球頭立銑刀

- |--- 2/4 刃平頭銑刀

- |--- 用於切削的 HRC55 方形立銑刀

- |--- 粗加工立銑刀

- |--- 倒角立銑刀

- |--- 整體硬質合金鑽頭

- |--- 硬質合金鉸刀

- |-- 金屬陶瓷立銑刀

- |- 下載

- |-- 幫助文檔

- |-- 文件下載

- |- 消息

- |-- 公司新

- |--- 新聞部

- |-- 行業新聞

- |- 照片

- |-- 員工相冊

- |-- 客戶案例

- |- 聯繫我們