Ukuguqulwa okuguqukayo: Ukukhetha okuhle kakhulu ezweni lokusika

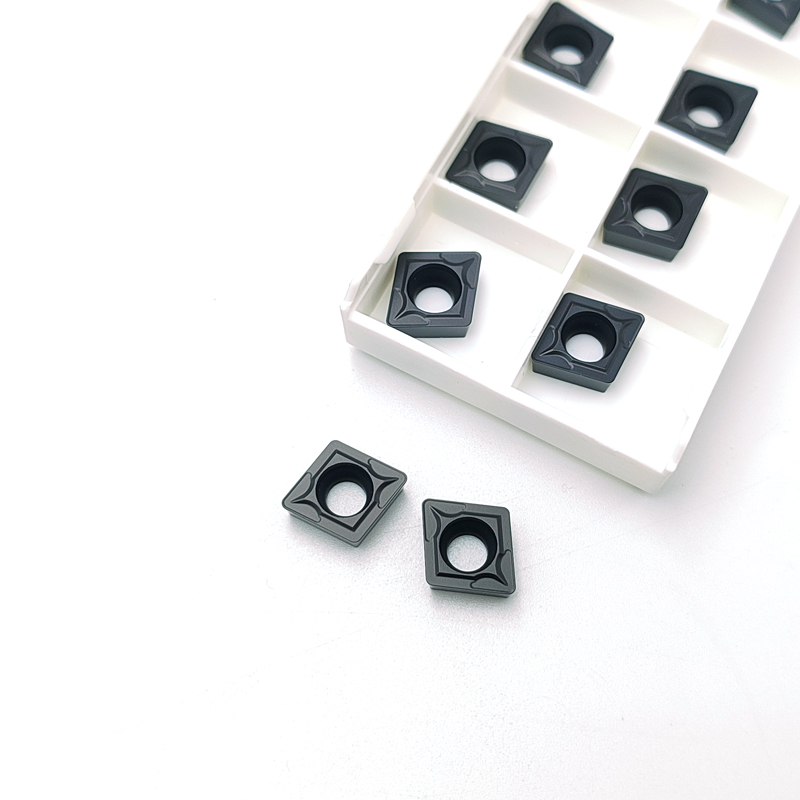

Ukuguqulwa okuguqukayoizingxenye zamathuluzi ezisetshenziswa emishini ye-lathe. Umsebenzi wabo oyinhloko ukususa impahla eyeqile kusuka endaweni yokusebenza ngokuhamba okuhlobene phakathi komsebenzi wokujikeleza kanye nokufakwa kwemishini, ngaleyo ndlela machine ngosayizi owufunayo. Kufana nethuluzi elinembile lokuqopha elinganciphisa izinto ezahlukahlukene futhi libamba iqhaza elibalulekile emkhakheni wokukhiqiza imishini.

Uma kuqhathaniswa namathuluzi endabuko, ukufakwa kwe-carbide Turning Inzuzo kunezindlela ezilandelayo

1. Ubulukhuni obuphezulu nokugqoka ukumelana:

Ubulukhuni be-carbide buphakeme kakhulu kunalokho kwezinto zamathuluzi endabuko, njengensimbi ephezulu. Lokhu kuvumela ukuguqulwa kwe-carbide ukufakwa ukuze kugcinwe ubukhali obuhle bemikhawulo ngesikhathi senqubo yokusika futhi kumelane nokugqokwa kwezinto zokwenza izinto ezisetshenziswayo ebala, ngaleyo ndlela kunwebe kakhulu impilo yenkonzo ye-blade. Isibonelo, lapho ucubungula izinto ezinobulukhuni obuphezulu njengensimbi ye-alloy nensimbi eqinile, ukumelana okuqinile kokufakwa kwe-carbide okusobala, kunciphisa imvamisa yokutshala okuzinzile, futhi kunciphise imvamisa yokubuyiselwa kwe-blade, futhi kuthuthukise ukusebenza kahle.

2. Amandla aphezulu kanye nobunzima:

Izinto ze-Carbide azigcini nje kanzima, kodwa futhi zinamandla athile nokuqina. Ekuguqukeni, bangamelana namandla amakhulu okusika kanye nomthelela amabutho, futhi abathambekele ekuphumeni nasekuphazamisekeni. Ngokuphambene, amathuluzi ensimbi endabuko athambekele ekuguqukeni nasekulimaleni lapho ngaphansi kwemithwalo emikhulu, ethinta ukunemba kokusebenza nokusebenza kahle kokukhiqiza.

3. Ukuqina okuhle okushisayo:

Kuzokhiqizwa inani elikhulu lokushisa ngesikhathi senqubo yokujika, okwenza ukuthi izinga lokushisa lamathuluzi likhuphuke. I-Carbide efakwe ngoCement inokumelana nokushisa okuphezulu nokuqina okushisayo, kusengagcina izakhiwo ezinhle zemishini emazingeni okushisa aphezulu, futhi akulula ukuthambisa noma ukuwohloka ngenxa yamazinga okushisa aphezulu. Lokhu kwenza ukuguqulwa kwe-carbide okufakiwe kwe-carbide ukuguqulwa kube nokuguquguquka okuhle ngaphansi kokusika okusheshayo, ukusika okusomile nezinye izimo zokusebenza, futhi kungaqinisekisa ikhwalithi yokucubungula nokunemba.

4. Ukunemba okuphezulu nokusebenza okuhle kokusika:

Ukunemba okukhiqizwayo kokufakwa kweCarbide Carbide Curning okuphezulu, kanye nokunemba okunobukhulu, ukunemba kwesimo kanye nekhwalithi ye-order yama-blade kungaqinisekiswa kahle. Lokhu kwenza ama-blade akwazi ukufezekisa ukusika okuqondile ngesikhathi senqubo yokusika, futhi amakhono asetshenzisiwe anokunemba okuphezulu okuphezulu kanye nekhwalithi enhle ebusweni. Ngasikhathi sinye, umphetho wokusika we-carbide ohlanganisiwe ubukhali futhi ukumelana nokusika kuncane, okunganciphisa amandla okusika namandla okusika, ukunciphisa umthwalo wamathuluzi womshini, futhi uthuthukise ukusebenza kahle.

I-5. Ububanzi bezicelo:

Ukufakwa kweCarbide Carbide Carbide kungakhetha izinto ezihlukile ze-blade, bobunjwa, osayizi kanye nezimbobo ngokuya ngezidingo ezahlukahlukene zokucubungula, futhi zilungele ukuguqulwa kwezinsimbi zezinto ezahlukahlukene, kufaka phakathi insimbi, ama-alloys aphezulu, njll.

Izimo Zokusebenza

1.Roughing:

Esigabeni esigoqisayo, ukuguqulwa okuguqukayo kusetshenziselwa ukususa ngokushesha inani elikhulu lezinto ezibonakalayo. Ngalesi sikhathi, ufaka ngemiphetho emikhulu yokusika nokuqina okunamandla kuvame ukukhethwa, njengokufakwa kwe-carbide yesikwele enkulu. Lokhu kufakwa kungabekezelela amandla amakhulu wokusika futhi usebenzise ukujula kokusika okukhulu nokuphakelwa kokwenza ngcono ukucubungula ukusebenza kahle. Ukwenza isibonelo, lapho izilonge izikhala zezingxenye ezinkulu shaft, ukufakwa okuvuthayo okuvuthayo kungasusa ngokushesha izinto ngokweqile futhi wenze umsebenzi wokusebenza eduze kwephrofayili yosayizi wokugcina.

2.Semi-finishing:

Isigaba sokuqeda ukuqeda ukuthuthukisa ukunemba okubucayi kanye nekhwalithi ephezulu yokwenziwa kwesisekelo sokuqina. Ngalesi sikhathi, ukuguqulwa okuguqukayo okukhethiwe kumele kube nokuqina okuhle nokunemba okulandelayo, okunjalonjengokufakwa kwe-carbide okwenziwe ngedayimane. Ngokunciphisa ngokufanele ukujula kokujula nokuphakelayo, umsebenzi wokwenziwa ucutshungulwa usebenzisa onqenqemeni olunembayo lokufaka ukulungiselela ukuqeda.

3.Finishing:

Ukuqeda kudinga ukuguqulwa kokuguqulwa ukuze ukwazi ukucubungula ukunemba okuphezulu, indawo ephansi yokhuni. Ngokuvamile, ama-blade anemiphetho ebukhali nokunemba okuphezulu kukhethiwe, njengokufakwa kwe-ceramic noma ukufakwa kwe-carbide ngezimbali ezinhle. Kulesi sigaba, ukujula kokusika kanye nezilinganiso zokuphakelayo zincane kakhulu, futhi ibala lisetshenziselwa ikakhulukazi ukwenza ukusika okuhle endaweni yokusebenza. Isibonelo, lapho kucutshungulwa izingxenye ezinengqondo eziphakeme njengemikhono, i-blade eguqukayo yokuqeda kungenza ukuthi i-workpiece surfaviece survice afinyelele ra0.8μm noma ngaphansi.

Amamodeli

1.Faka ngokwezinto ezibonakalayo:ikakhulukazi ama-blades ajika ama-carbide, ama-cramic ajika amabala, ama-carwamic ceramic ajika amabala, njll. Ama-Carbide Turning Blades anobulukhuni obuphezulu nobunzima, efanelekile ukucubungula izinto eziningi; Amabala wokujika ama-ceramic anobunzima obuphakeme futhi agqoke ukumelana, alungele ukusika okusheshayo nokucubungula izinto ezinzima; Ama-Metal Ceramic Turning Blades ahlanganisa izinzuzo ze-carbide ne-ceramics, ngokusebenza okuhle kokusika nokugqoka ukumelana.

I-2.Classification ngesimo:Okuvamile kungunxantathu, isikwele, idayimane, umbuthano, njll. I-Blades eguqukayo yezimo ezahlukahlukene ilungele amathuba ahlukene okucubungula, ngokwesibonelo, ama-blade anxantathu alungele ukucutshungulwa okunamandla nokuqeda, futhi amabala edayimane enza kahle ekusebenzeni kwentambo.

3.Classifing ngokusebenzisa:Kubandakanya ama-blades aguqulayo angaphandle, umgodi wangaphakathi wokuguqula amabala, ukusika ama-blades, ama-blade ajika, njll. Uhlobo ngalunye lwe-blade lube nedizayini yalo ethile futhi ngisebenzisa ukufeza izidingo ezahlukahlukene zokucubungula.

Isici seMikhiqizo

Ukunemba nokuqina:Unomsebenzi ohlukahlukene ongejwayelekile njengobulukhuni obuphezulu, gqoka ukumelana kanye nezinga eliphakeme lokuqeda ukuqinisekisa ukuphuma okubushelelezi kwe-chip.

Ubuchwepheshe be-2.adwads ukuqinisekisa: Ubukhali nokuqina okwenziwe ngobuchwepheshe obuphambili obuphezulu bokunemba futhi bunamandla aqinile kanye nesikhathi sokuphila isikhathi eside, nge-Cutting Edge Sharper kanye nokugqokwa okwengeziwe.

3.Khetha ukuqina nokuqina okulula:Ama-blades anembe ephezulu ukunciphisa ukugqokwa ngokuncipha kwengxabano, mancane amathuba okubangela ukunamathela noma ukuqhekeka okuphukile.

Umkhiqizo wethu ukhombisa