Zisetshenziselwa ini ukufaka i-carbide?

Ukufakwa kwe-Carbide kudlala indima ebalulekile ekusebenzeni kwemishini yesimanje kuzo zonke izimboni ezahlukahlukene, ngenxa yokuqina kwazo.

ukuqina okukhethekile, ukuguquguquka, nokunemba. Lezi zinto ezifakiwe zisetshenziswa ngobuningi bokusika nokubunjwa

izinqubo, ezihlinzeka ngezinzuzo ezibalulekile ngaphezu kwamathuluzi ensimbi esivinini esikhulu esivamile. Kulesi sihloko, sihlolisisa

izinhlelo zokusebenza, izinzuzo, kanye nokucatshangelwa okubalulekile okuhlotshaniswa nokufakwa kwe-carbide.

Isingeniso seCarbide Insert:

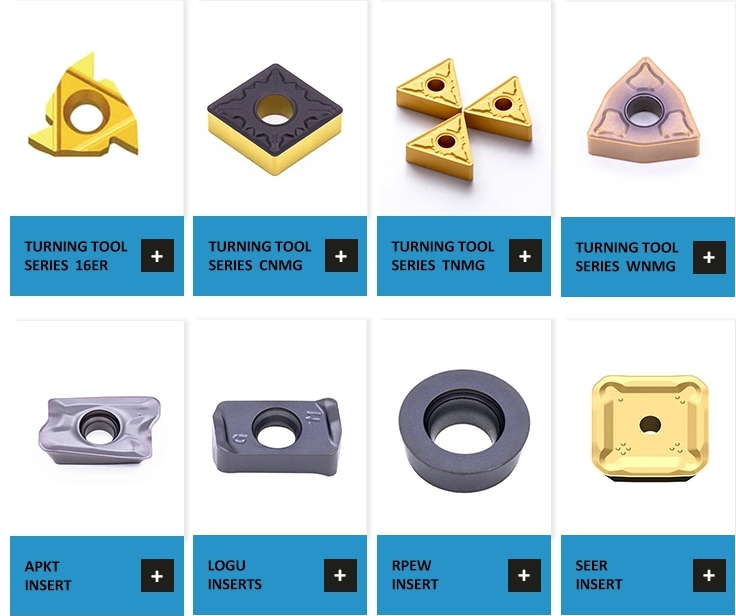

UChuangde ungumkhiqizi nomsabalalisi wamathuluzi okusika i-carbide nemikhiqizo ehlobene esekelwe eZhuzhou, eChina. Le nkampani ikhiqiza amathuluzi okusika i-carbide asetshenziswa emishinini nasezinqubweni zensimbi zokuqina nokumelana nokugqoka. Lokhu kufaka phakathi izinto ezifakwayo, izigayo, izinsimbi, ama-reamer, ama-burr, kanye namathuluzi akhethekile. Imikhiqizo yayo yakhelwe ukusebenza kwe-Metal.Sinikeza amanani aphezulu okuncintisana nemikhiqizo yekhwalithi. Ikhona esitokweni, isampuli yamahhala.

Izicelo:

I-Carbide inserts isetshenziswa kakhulu ekuguquleni intambo, ukusika kanye noku-grooving njll. Kuyinketho enhle yokwenza ama-roughing, semi-finishing, finishing.general machining yensimbi, insimbi engagqwali ne-cast iron.

1. Ukuphenduka nokugaya: Okufakwayo kwe-Carbide kusetshenziswa kakhulu ekuguquleni nasekugayeni imisebenzi yonkana

uhla lwezinto ezibonakalayo, okuhlanganisa insimbi, insimbi engagqwali, insimbi ecijile, i-aluminium, nama-alloys asezingeni lokushisa eliphezulu.

Bahamba phambili ekudaleni amakhonsathi anembile, izintambo, nezindawo ezinomphetho ongaphezulu.

2. Ukubhoboza Nokuyisicefe: I-Carbide inserts isetshenziswa ekubholeni nasezinhlelweni eziyisicefe ukudala izimbobo

ukujula nobubanzi obuhlukahlukene. I-conductivity yabo ephezulu yokushisa kanye nokumelana nokuguqulwa kuqinisekisa

ukusebenza okungaguquki ngisho nasezimeni zokumba eziyinselele.

3. Uchungechunge: Ukufakwa kwe-Carbide kukhethwa ekusebenzeni kwentambo ngenxa yekhono labo lokugcina libukhali

ukusika imiphetho ngokusetshenziswa isikhathi eside, okuholela kumaphrofayili entambo anembile nokuncipha kokugqoka kwamathuluzi.

4. I-Grooving kanye Nokwehlukana: Ukufakwa kwe-Carbide kusiza ukusebenza kahle kwe-grooving kanye nokuhlukanisa, okwenza kube lula

ukwakhiwa kwamashaneli emincane kanye nokuhlukaniswa kwezinto zokusebenza ezinokumoshwa okuncane.

5. I-High-Speed Machining (HSM):Ukufakwa kwe-Carbide kubalulekile ezinhlelweni ze-HSM lapho okokusebenza okusheshayo

amazinga okususwa abalulekile. Ukuqina kwazo okuphakeme nokuzinza kokushisa kwenza kube nesivinini esiqhubekayo sokusika

kanye namazinga okuphakelayo, athuthukisa ukukhiqiza kanye nokuphumelela kwezindleko.

Izinzuzo:

1. Impilo Yethuluzi Elinwetshiwe:Okufakwayo kwe-Carbide kubonisa impilo yamathuluzi ende kakhulu uma kuqhathaniswa nesivinini esivamile esivamile.

amathuluzi ensimbi, ukunciphisa ukushintsha kwamathuluzi kanye nesikhathi sokuphumula.

2. Ukukhiqiza Okuthuthukisiwe: Ukusebenza okuphakeme kokusika kanye nokumelana nokugqoka kokufakwa kwe-carbide kubangela umphumela

isivinini semishini esheshayo kanye nokukhuphuka kokuphuma komsebenzi, okuthuthukisa ukukhiqiza okuphelele.

3. I-Surface Finish Ethuthukisiwe: Ukufakwa kwe-Carbide kukhiqiza ukuqedwa okubushelelezi okunama-burrs amancane kanye nokukhubazeka,

ukususa isidingo sokuqedela imisebenzi yesibili kanye nokwenza ngcono ingxenye yekhwalithi.

4. Ukuguquguquka: Okufakwayo kwe-Carbide kuyatholakala ngezinhlobonhlobo zejometri, ama-coatings, namabanga aklanyelwe

izinhlelo zokusebenza ezithile zemishini, ezinikeza ukuguquguquka nokuguquguquka ekukhetheni amathuluzi.

5. Ukonga Izindleko: Naphezu kwezindleko zabo zokuqala eziphakeme, ukufakwa kwe-carbide kuletha izindleko ezingcono kakhulu kune

ubude besikhathi sokuphila ngenxa yezindleko ezincishisiwe zamathuluzi, ukukhiqiza okuthuthukisiwe, nezindleko eziphansi zokwenza imishini ngayinye.

Sengiphetha, ukufakwa kwe-carbide kumelela itshe legumbi lobuchwepheshe besimanje bemishini, obunikeza ukusebenza okungenakuqhathaniswa, ukuguquguquka, kanye nokusebenza kahle kwezindleko ezinhlotsheni ezahlukahlukene zezinhlelo zokusebenza.