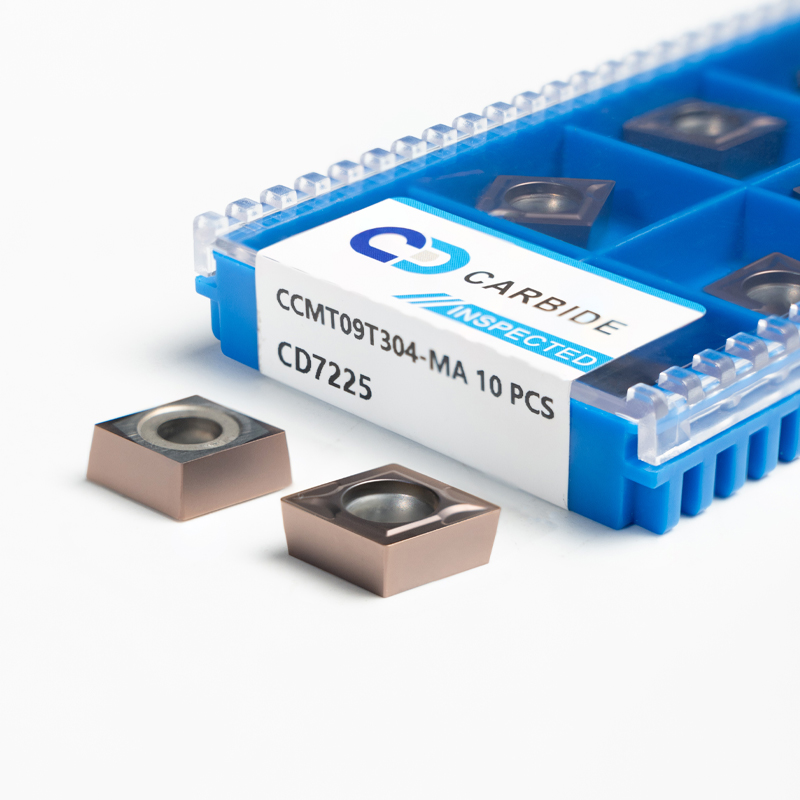

- Grade: CD7225

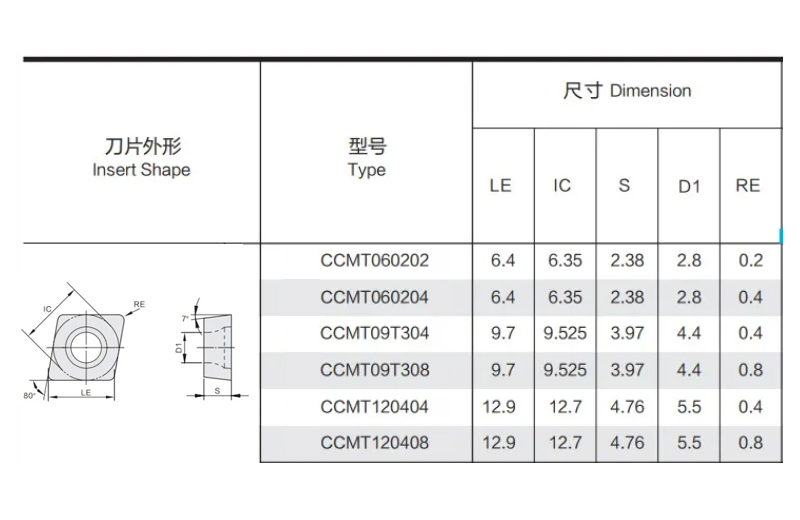

- Model: CCMT09T304-MA DCMT11T308-MA

- Coating:PVD

- Application: Used for steel hard material, stainless steel processing

DESCRIPTION

Cemented tungsten carbide turning insert CCMT09T304-MA DCMT11T308-MA for CNC Lathe Machine

1.Product description:

2.Grades:

1.High precision and stiffness

Possess various outstanding performances such as high hardness,wear resistance as well as high degree of finish to ensure smooth chip evacuation.

2.Advanced Technology to ensure

sharpness and durability Manufactured through advanced high-precision technology and has stronger general stiffness as well as longer lifetime,with the cutting edge sharper and more wear resistant.

3.Quench Hardening and Easy Milling

High-precision Blades to Reduce wear by decreasing friction,less likely to cause blade sticking or broken fracture.

Why Choose us

1. 100% new raw Materials

4. Large stock available for regular items to make fast delivery.

FAQ

1) Ngingayithola nini intengo?

Sivame ukucaphuna kungakapheli amahora angu-24 ngemva kokuthola umbuzo wakho.Uma uphuthuma kakhulu ukuthola inani, sicela usishayele noma usitshele ku-imeyili yakho ukuze sizobheka umbuzo wakho oza kuqala.

2) Ngingayithola kanjani isampula ukuhlola izinga lakho?

Ngemuva kokuqinisekiswa kwentengo, ungadinga amasampula ukuze uhlole ikhwalithi yethu. Uma nje udinga isampula elingenalutho ukuze uhlole ukwakheka kanye nekhwalithi yephepha, sizokunikeza isampula mahhala, inqobo nje uma ukwazi ukukhokhela impahla esheshayo.

3) Ngingalindela isikhathi esingakanani ukuthola isampula?

Ngemva kokukhokha inkokhiso yesampula futhi usithumelele amafayela aqinisekisiwe, amasampula azobe elungele ukulethwa ezinsukwini ezingu-3-7. Amasampula azothunyelwa kuwe nge-express futhi afike ezinsukwini zokusebenza ezi-3-7. Ungasebenzisa i-akhawunti yakho ye-express noma usikhokhele kusengaphambili uma ungenayo i-akhawunti.

4) Ngabe yonke inqubo yenziwa isikhathi esingakanani?

Ngemva kokufaka i-oda, isikhathi sokuphatha ukukhiqiza singaba yizinsuku ezingama-20-25. Sidinga izinsuku eziyi-7 ukulungisa zonke izinto bese kuba yizinsuku eziyi-15 zokukhiqiza.

5) Kuthiwani ngosuku lokuhamba nokulethwa?

Imvamisa sisebenzisa ukuthunyelwa ukudlulisa impahla.Kungaba yizinsuku eziyi-7-25.Futhi kuya ngokuthi ukuyiphi i-coutry nechweba.Kungaba kufushane uma udinga ukuthumela impahla efana ne-Asian. Uma kunezimo eziphuthumayo singathumela izimpahla nge-air Express, inqobo nje uma ukwazi ukukhokhela izindleko zomgwaqo.

6) Ingabe uyinkampani yokuhweba noma umenzi?

Singumkhiqizi ochwepheshe. Asigcini nje ngokuba ngabanikazi bemboni yethu yamathuluzi, kodwa futhi sinefektri ye-carbide enosimende.

7) Ikuphi imboni yakho?

Sitholakala edolobhaneni lase-Zhuzhou, esifundazweni sase-Hunan., i-tungsten carbide base town yase-China.

8) Ngingalindela isikhathi esingakanani ukuthola isampula?

Ngemva kokukhokha inkokhiso yesampula futhi usithumelele amafayela aqinisekisiwe, amasampula azobe elungele ukulethwa ezinsukwini ezingu-3-7. Amasampula azothunyelwa kuwe nge-express futhi afike ezinsukwini zokusebenza ezi-3-5. Ungasebenzisa i-akhawunti yakho ye-express noma usikhokhele kusengaphambili uma ungenayo i-akhawunti.

9) Kuthiwani ngesitoko sakho?

Sinemikhiqizo eningi esitokweni, izinhlobo ezivamile namasayizi konke kusesitokweni.

10) Ingabe ukuthunyelwa kwamahhala kungenzeka?

Asinikezi isevisi yamahhala yokuthumela. Singaba nesaphulelo uma uthenga imikhiqizo eningi

Zizwe ukhululekile ukuxhumana nami:

Aimee

Umphathi wezentengiso

Inkampani Zhuzhou Chuangde Cemented Carbide Co

215, building 1, International Students Pioneer Park,

TaishanRoad, Tianyuan District, Zhuzhou City.

I-imeyili: cd@cdcarbide.com

Tel:+86-731-22506139

Mobile:+8613786352688

Whatspp/wechat/Skype : 0086 13786352688