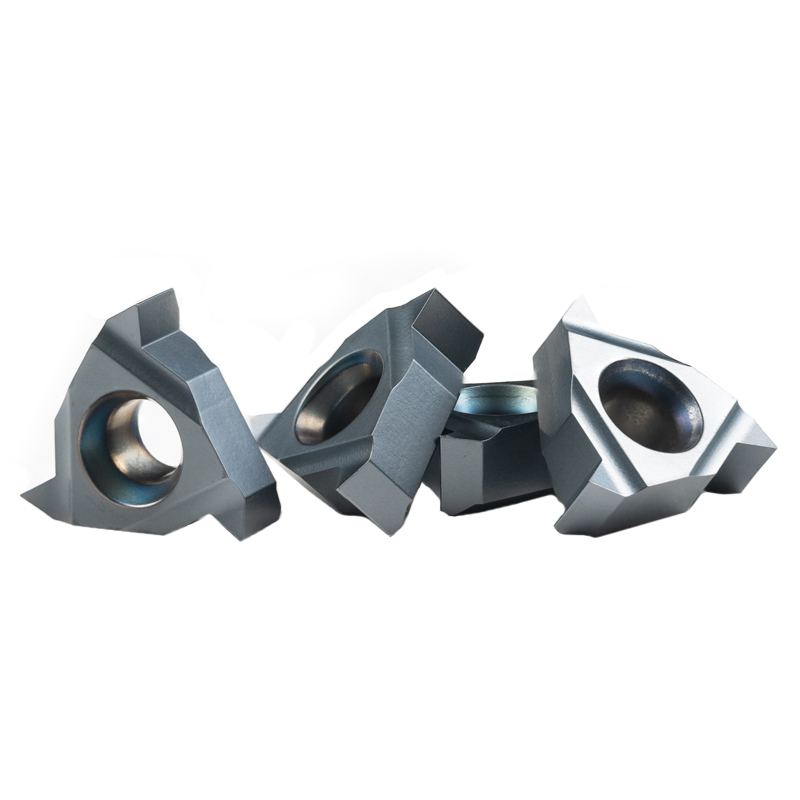

El cor de la dissipació de calor de tall d'alta velocitat i el disseny resistent al desgast de fulles CNC d'alt rendiment

—— CDCARBIDE CNC Tool Factory Remoda el futur del processament de metalls amb tecnologia patentada

Sota l’onada de fabricació intel·ligent i indústria 4.0, la tecnologia de tall d’alta velocitat s’ha convertit en el motor principal per millorar

Eficiència de processament. Com el cor del tall d’alta velocitat, el rendiment de les fulles CNC determina directament la precisió del processament, la vida de l’eina

i cost de producció. Amb diverses tecnologies patentades i innovació contínua d’equips tècnics professionals, Cdcarbide CNC Tool

La fàbrica ha llançat una solució de fulla d’alt rendiment amb dissipació de calor i resistència al desgast com a nucli, proporcionant un preu de fàbrica d’alta qualitat

Productes d’eines per a clients dels camps d’automòbils, aeroespacials, motlles, etc., ajudant la indústria a trencar el coll d’ampolla d’eficiència.

1. Disseny de dissipació de calor La forma tranquil·la del tall d’alta velocitat

Durant el tall d’alta velocitat, l’alta temperatura generada per la fricció entre la fulla i la peçafarà que la vora es suavitzi, agreuja el desgast i, fins i tot, causi una deformació del processament. Cdcarbide en fa servir tres

Tecnologies patentades de dissipació de calor per controlar la temperatura de tall en el rang ideal

Estructura de ranura de refrigeració de gradient La superfície de la fulla adopta una ranura de refrigeració en espiral dissenyada per bionics,

Combinat amb un angle de vora precís, de manera que el líquid de tall pugui arribar directament a la zona d’alta temperatura,

i l'eficiència de la dissipació de calor s'incrementa un 40%.

Recobriment conductor tèrmic nano El recobriment compost de TialN-WCC desenvolupat de manera independent té un 25%

una conductivitat tèrmica més elevada que els recobriments tradicionals, que transfereix ràpidament la calor al mànec per evitar -ho

Sobreescalfament de la vora.

Tecnologia de dispersió de la tensió dinàmica Optimitzar l'estructura de la matriu de la fulla mitjançant l'anàlisi d'elements finits

Per reduir la concentració d’estrès de tall i reduir el risc de deformació tèrmica.

2. Disseny resistent al desgast Força dura per suportar unes condicions laborals dures

Cdcarbide ha creat materials difícils de processar com ara acer inoxidable i aliatge de titani

Sistema de fulla resistent a ultra-desgast mitjançant la innovació col·laborativa del procés de materials-estructures

La matriu de carbur de grau ultrafí de gra ultrafí 90% WC-10% CO CO Ultrafine Powder (mida de gra 0,5 μm) s’utilitza,

amb una duresa de HRA93.5 i una força de flexió de més de 4.000MPa.

Recobriment compost de xapa d'ions multi-arc que combina la capa de transició TICN amb la capa superior Alcrn,

Es forma una estructura protectora de tres capes de resistent a la corrosió dura, que encara manté alta

Duresa a temperatures altes.

Tecnologia de passivació patentada a través d’equips de passivació làser intel·ligents, el radi de vora

es controla precisament a 2-5 μm, equilibrant la nitidesa i la resistència al desgast.

L’avanç tècnic en el processament d’aliatges de titani, la vida única de les fulles de cdcarbide supera

800 minuts, superant amb escreix la mitjana de la indústria.

Iii. El valor complet de la cadena de Cdcarbide de la tecnologia de la tecnologia a la tecnologia

Com a fàbrica d’eines CNC professional, el cdcarbide no només proporciona fulles d’alt rendiment, sinó que també condueix

Tecnologia + Servei per crear un valor a llarg termini per als clients

Capacitats personalitzades de R + D en resposta a les necessitats especials del client, l'equip tècnic professional pot

Proporcioneu solucions d’optimització d’eines en un termini de 72 hores, donant suport a serveis personalitzats com ara material

Adaptació i disseny de ranures.

SmGarantia de fabricació d’art La fàbrica està equipada amb equips avançats com ara alemany de cinc eixos

Les rectificadores d’enllaç i els forns de sinterització japonesos de buit per aconseguir un control de qualitat de procés complet de RAW

Materials per a productes acabats.

Mode de subministrament directe de fàbrica Elimina els enllaços intermedis, redueix els costos de contractació dels clients a

Els preus de la fàbrica i prometen millorar el rendiment del cost de productes similars en més del 15%.

Avanç amb el nucli per definir un nou punt de referència per al tall d’alta velocitat

En el camp del tall d’alta velocitat, Cdcarbide CNC Tool Factory continua liderant la innovació de la indústria amb

Els dobles avantatges de la dissipació de calor i el disseny resistent al desgast, múltiples tecnologies patentades i

Suport a l’equip professional. Tant si es tracta d’un rendiment estable en condicions de treball complexes com de cost

L’optimització de la fabricació verda, el cdcarbide sempre té un alt rendiment, alta fiabilitat i alta

Servei com a nucli per ajudar els clients a aprofitar la iniciativa en l'era de la fabricació intel·ligent.

L’elecció de cdcarbide significa triar

✅ Garantia de qualitat de la fàbrica d’eines CNC professional

✅ Revolució de l'eficiència impulsada per la tecnologia patentada

✅ Avantatge de costos aportat pel preu de la fàbrica